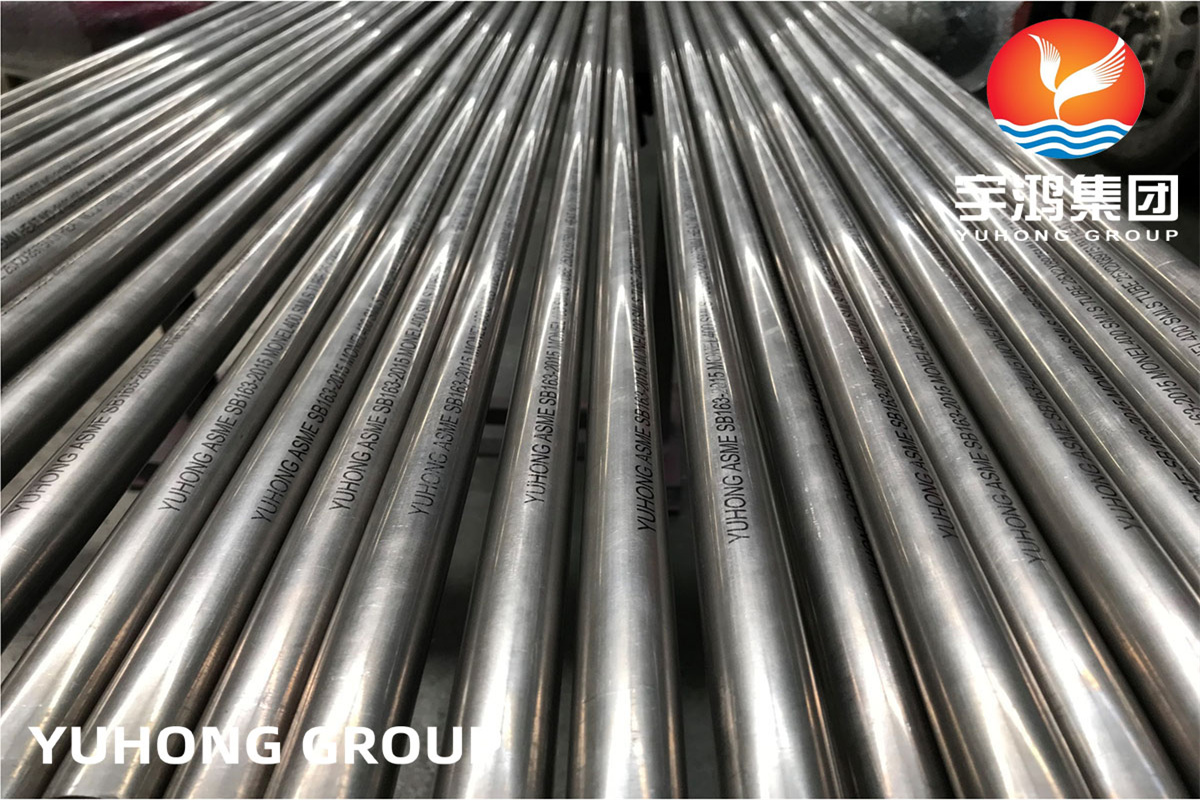

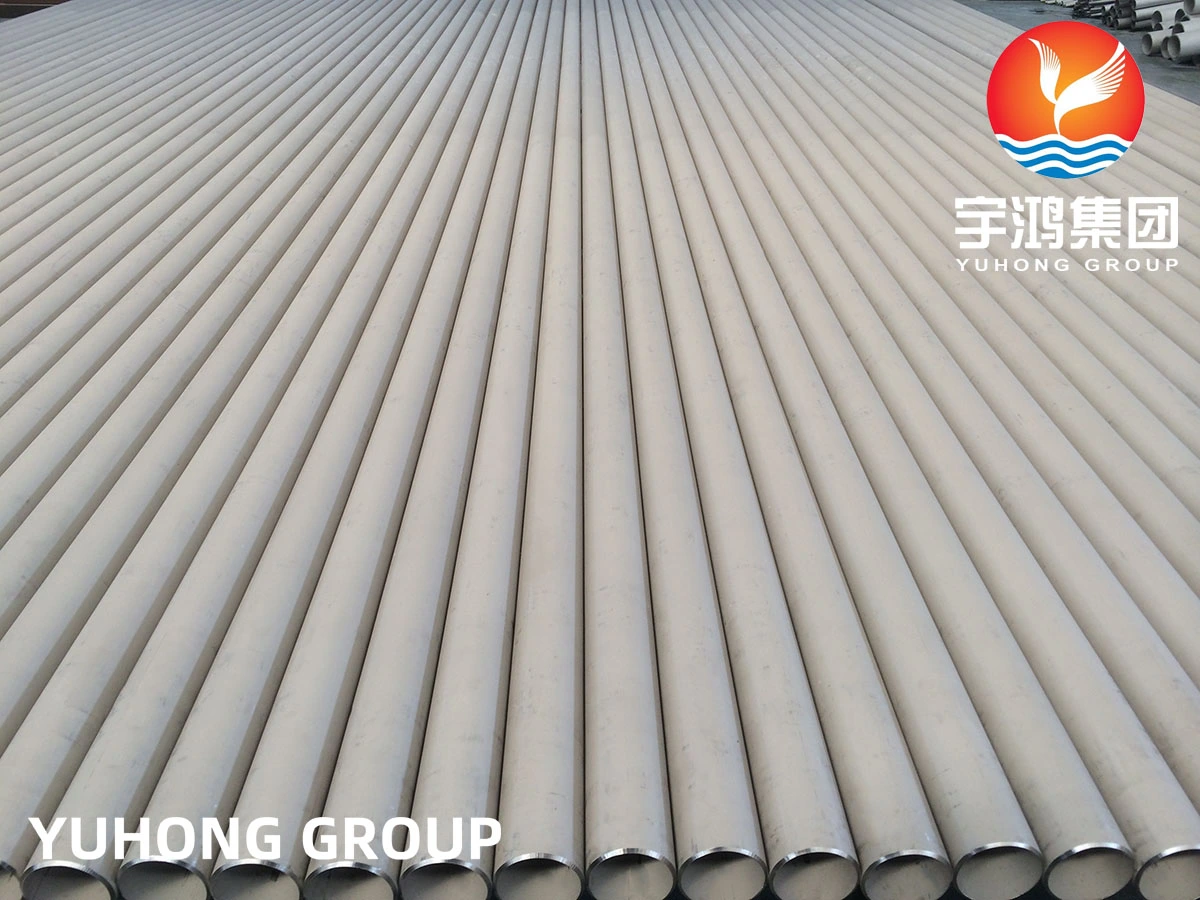

A seamless tube is a type of tube or pipe made from a solid billet that is heated and then stretched over a series of mandrels until it achieves the desired size and thickness. Unlike welded tubes, seamless tubes have no seam or weld joint. This results in a uniform and continuous structure throughout the length of the tube, allowing for thicker walls and higher strengths.

Yuhong Group is a seamless tube manufacturer, offering products in various material grades and standards:

Stainless Steel: TP304,TP304L,TP316,TP316L,TP316H,TP321,TP321H,TP347,TP347H,etc

Duplex Steel: UNS S31803, S32205, S31500, S32750, S32760, S32304, S32900

Seamless Stainless Steel Tubes: ASTM A213/ASTM A268/ASTM A269,etc

Seamless Stainless Steel Pipes: ASTM A312, etc

Seamless Duplex Steel tubes: ASTM A789, etc

Seamless Duplex Steel Pipes: ASTM A790, etc

For those seeking tailored solutions, our skilled team is ready to provide bespoke customization services.

Features of Seamless Tube and Pipe

High Strength and Durability: Seamless steel tubes are renowned for their exceptional strength and durability.

Leak Resistance: With no weld seam, these tubes are less likely to develop leaks.

Pressure and Stress Tolerance: Seamless tubes can withstand higher pressures and stresses due to their continuous steel construction.

Uniform Wall Thickness: The manufacturing process ensures a consistent wall thickness throughout the tube.

Consistent Material Properties: Seamless tubes have uniform material properties, which are crucial for certain engineering applications.

High-Temperature Tolerance: These tubes can endure high temperatures, making them ideal for use in boilers, heat exchangers, and other high-temperature applications.

Applications of Seamless Tube and Pipe

Due to their features, seamless steel tubes are used in a wide range of industries and applications, including automotive, aerospace, construction, oil and gas, and manufacturing. They are often preferred for critical applications where safety and performance are paramount.

English

English

_副本.webp)

_副本.webp)