In the ever-evolving landscape of the oil and gas industry, the quest for efficiency and reliability is unending. One crucial aspect that often goes unnoticed but plays a pivotal role in ensuring seamless operations is the choice of materials and components. Hastelloy tube fittings have emerged as unsung heroes, connecting the dots and contributing to the uninterrupted flow of oil and gas operations.

The Unrivaled Properties of Hastelloy

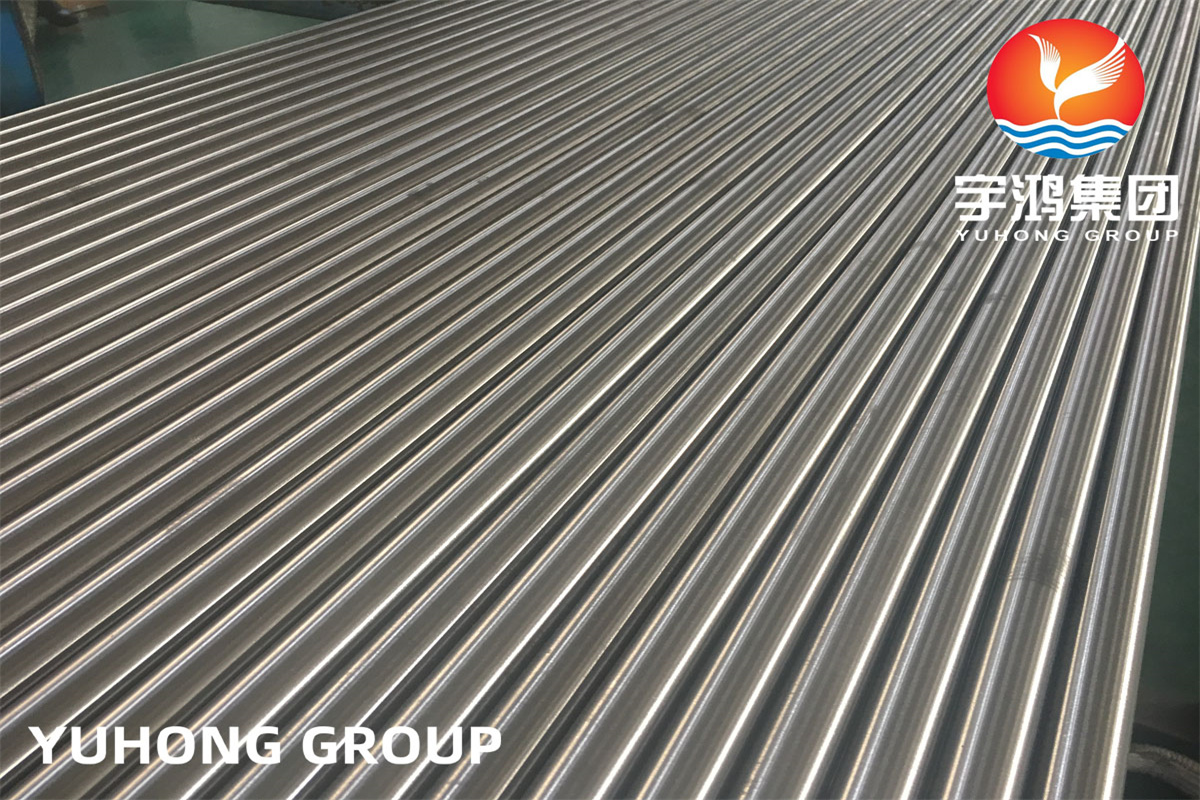

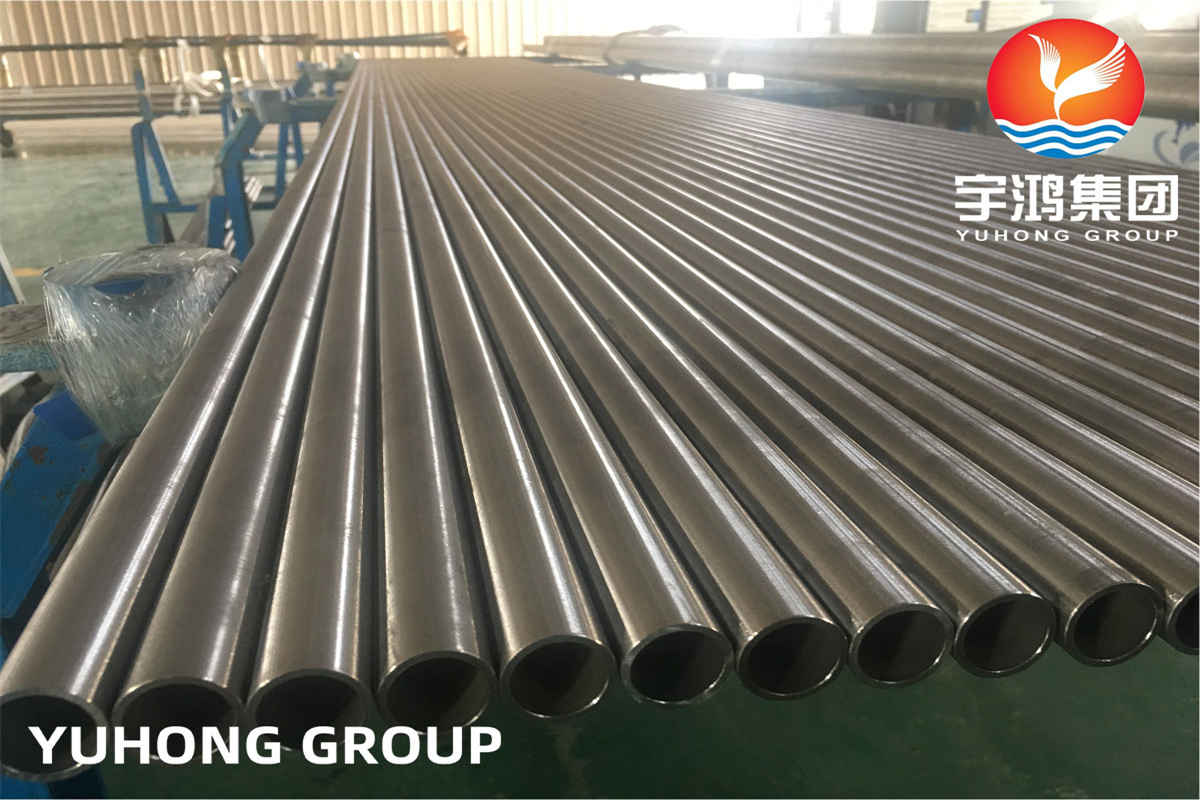

Hastelloy, a nickel-based alloy, boasts exceptional corrosion resistance, high strength, and durability. These properties make it an ideal choice for tube fittings in the harsh and corrosive environments prevalent in the oil and gas sector. Whether exposed to corrosive chemicals, extreme temperatures, or high pressures, Hastelloy stands strong, ensuring the integrity of the entire system.

Corrosion Resistance: A Game-Changer in Hostile Environments

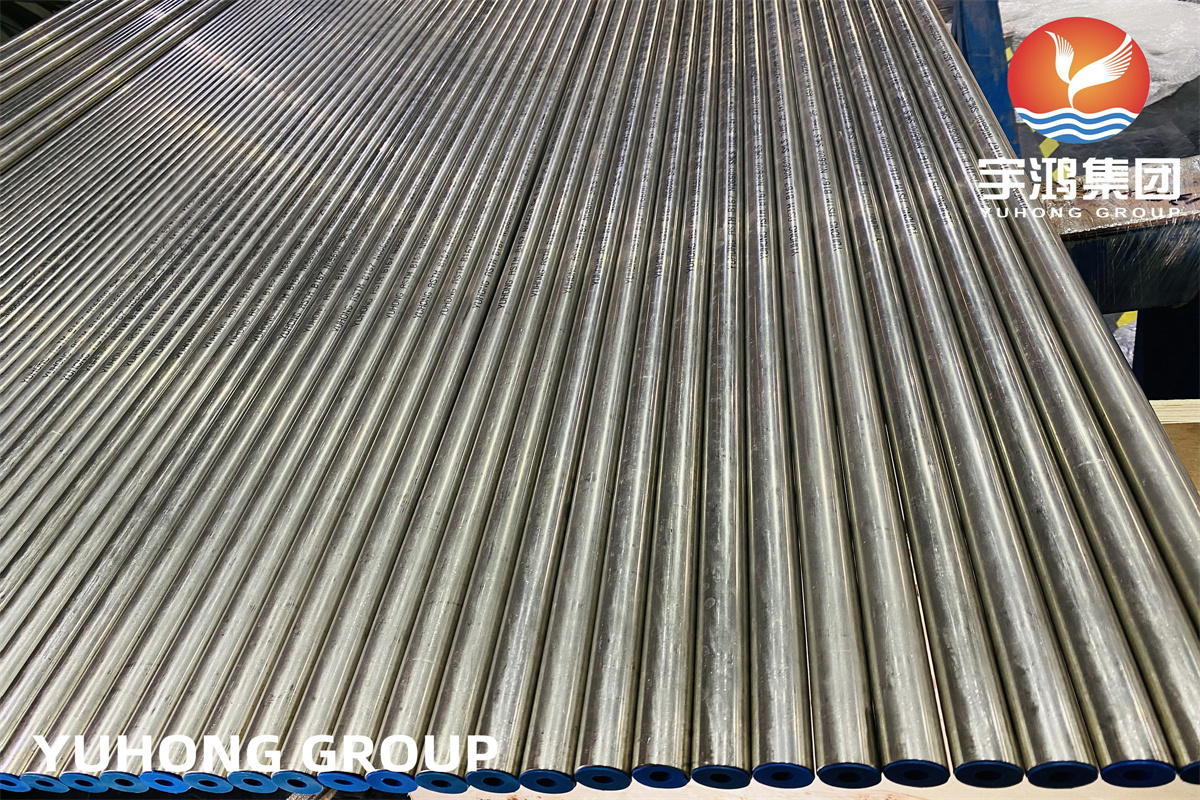

Oil and gas operations often take place in aggressive environments that can lead to corrosion-related failures. Hastelloy tube fittings act as a shield against corrosion, preventing leaks and ensuring the safety and longevity of the equipment. This resistance to corrosion is particularly crucial in offshore drilling operations, where exposure to saltwater can wreak havoc on traditional materials.

Seamless Integration for Efficient Operations

Efficiency is the lifeblood of the oil and gas industry. Hastelloy tube fittings facilitate seamless integration within the intricate network of pipelines and equipment. Their precise design and compatibility ensure a tight fit, reducing the risk of leaks and inefficiencies. This seamless integration contributes to the overall efficiency of the operation, enabling a smooth and continuous flow of oil and gas.

Meeting Stringent Safety Standards

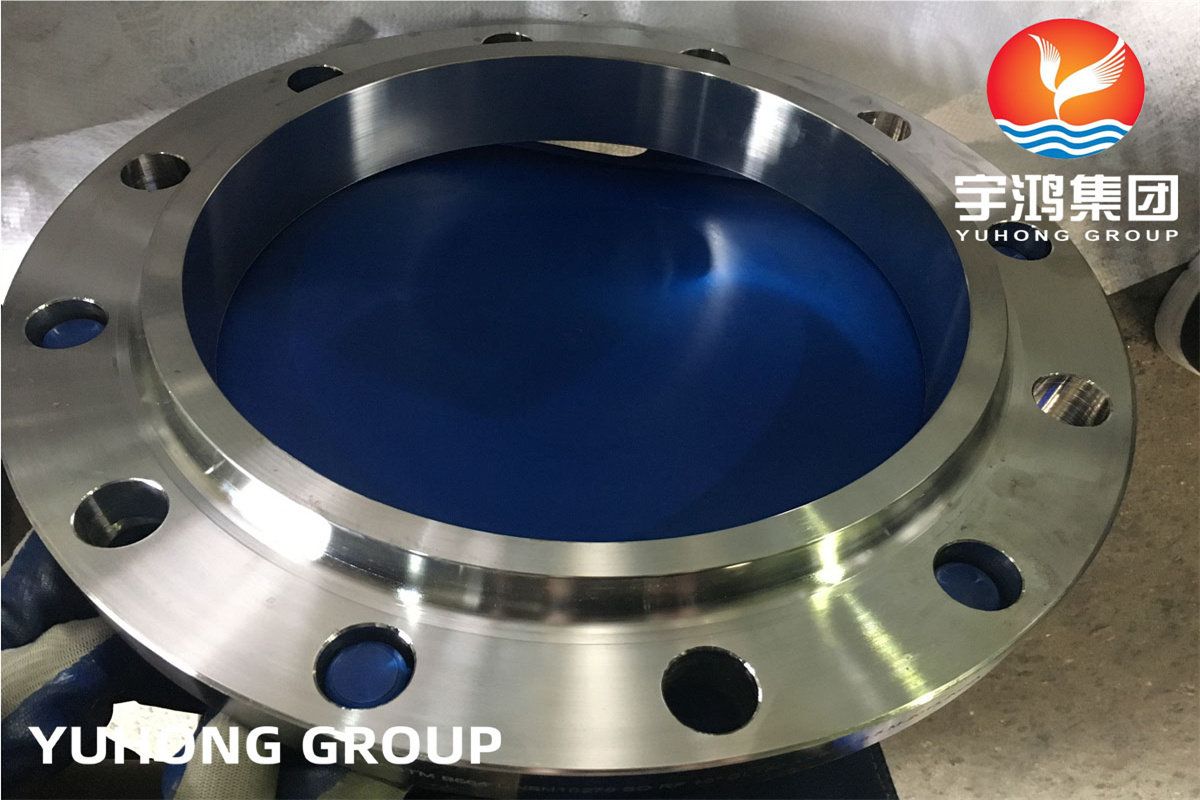

Safety is paramount in the oil and gas sector, and choosing the right materials for equipment is non-negotiable. Hastelloy's ability to withstand extreme conditions and resist corrosion aligns with the stringent safety standards of the industry. By incorporating Hastelloy tube fittings, companies can enhance the reliability of their systems, reducing the likelihood of accidents and ensuring the well-being of personnel and the environment.

The Future of Oil and Gas Relies on Resilient Materials

As the oil and gas industry continues to evolve, the demand for resilient materials that can withstand the challenges of modern extraction and processing methods is on the rise. Hastelloy tube fittings, with their proven track record, are poised to play a significant role in shaping the future of the industry. Their contribution to reducing downtime, enhancing safety, and optimizing operations positions them as a crucial element in the quest for sustainability and efficiency.

In the intricate tapestry of oil and gas operations, every component plays a vital role. Hastelloy tube fittings may go unnoticed, but their impact on the seamless flow of operations is undeniable. As the industry marches towards a future marked by innovation and sustainability, the role of robust materials like Hastelloy becomes increasingly prominent, ensuring that the dots are connected for a reliable and efficient energy sector.

English

English

_副本.webp)