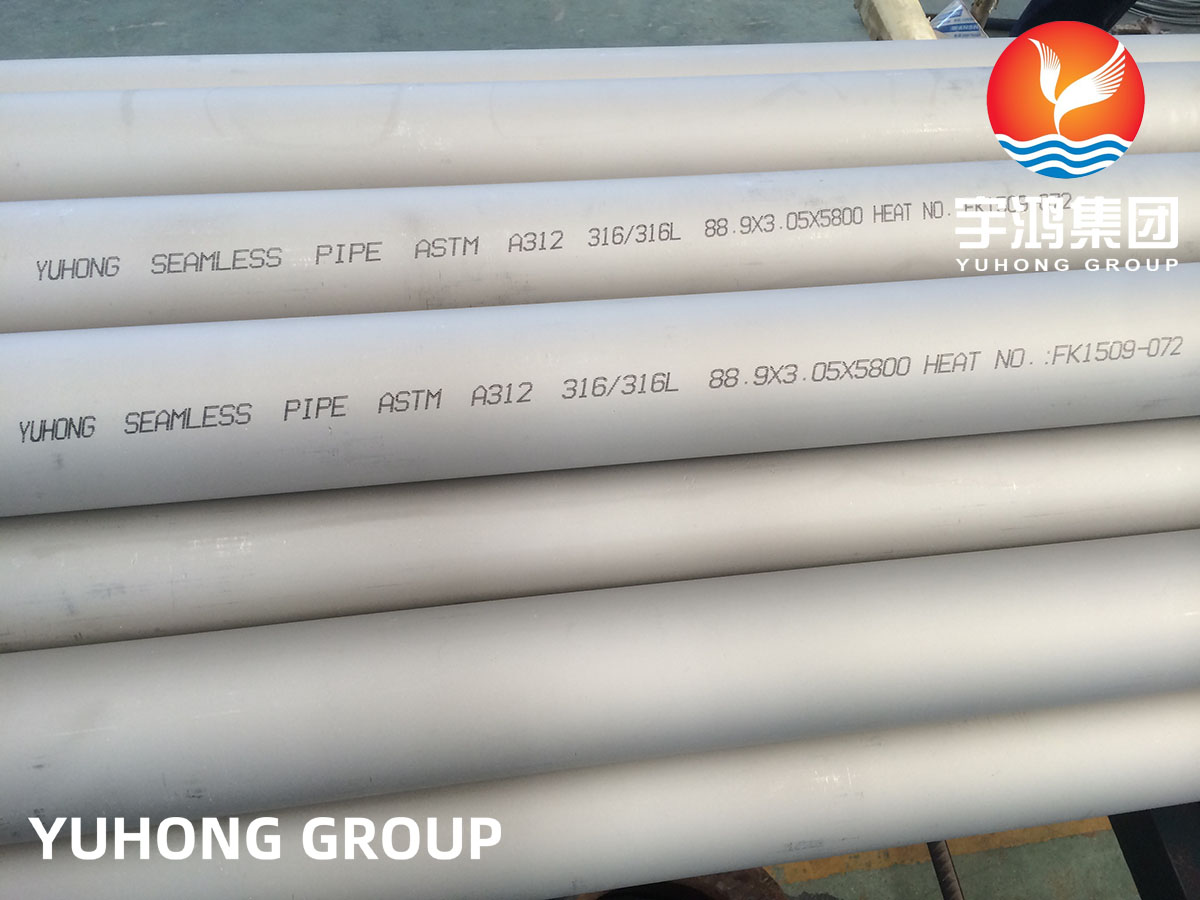

As we all know, the price of 316 stainless tube is more expensive than that of 304 stainless tube. There are many customers who consult the performance differences between the two. The difference in their application is the most consulted topic for stainless tubes 304 and 316.

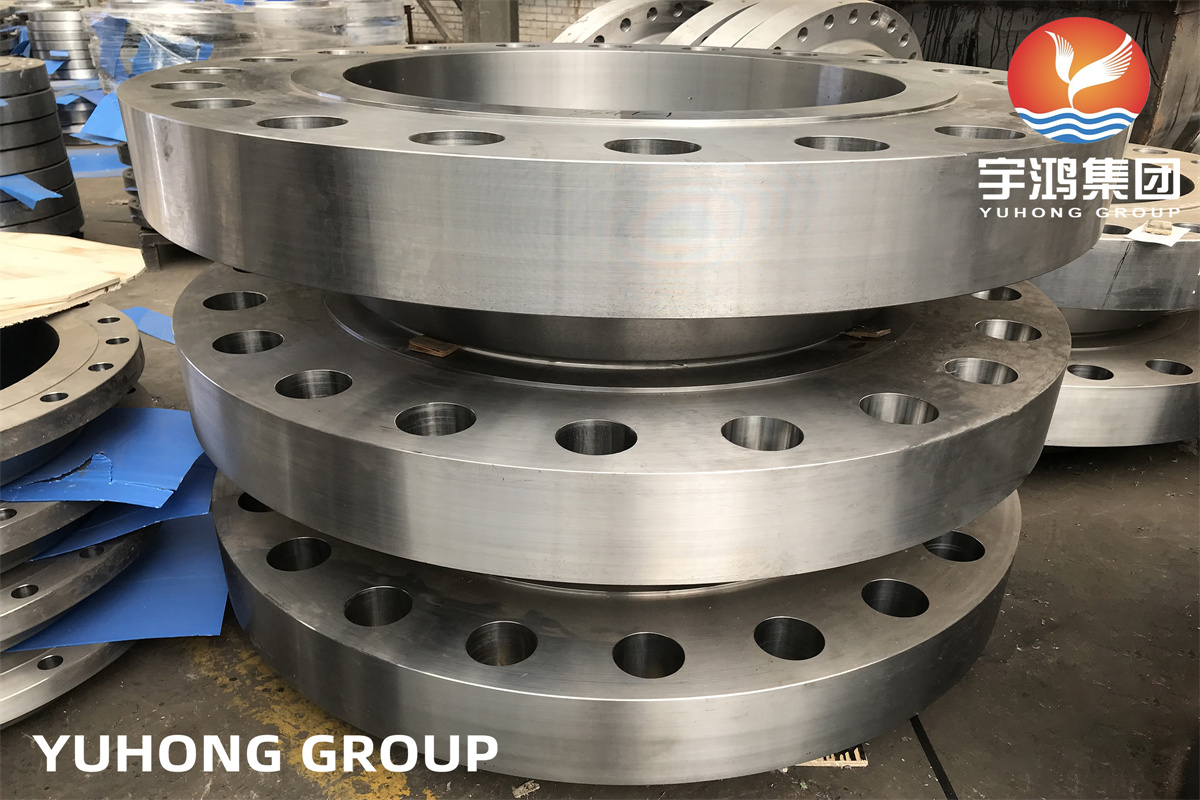

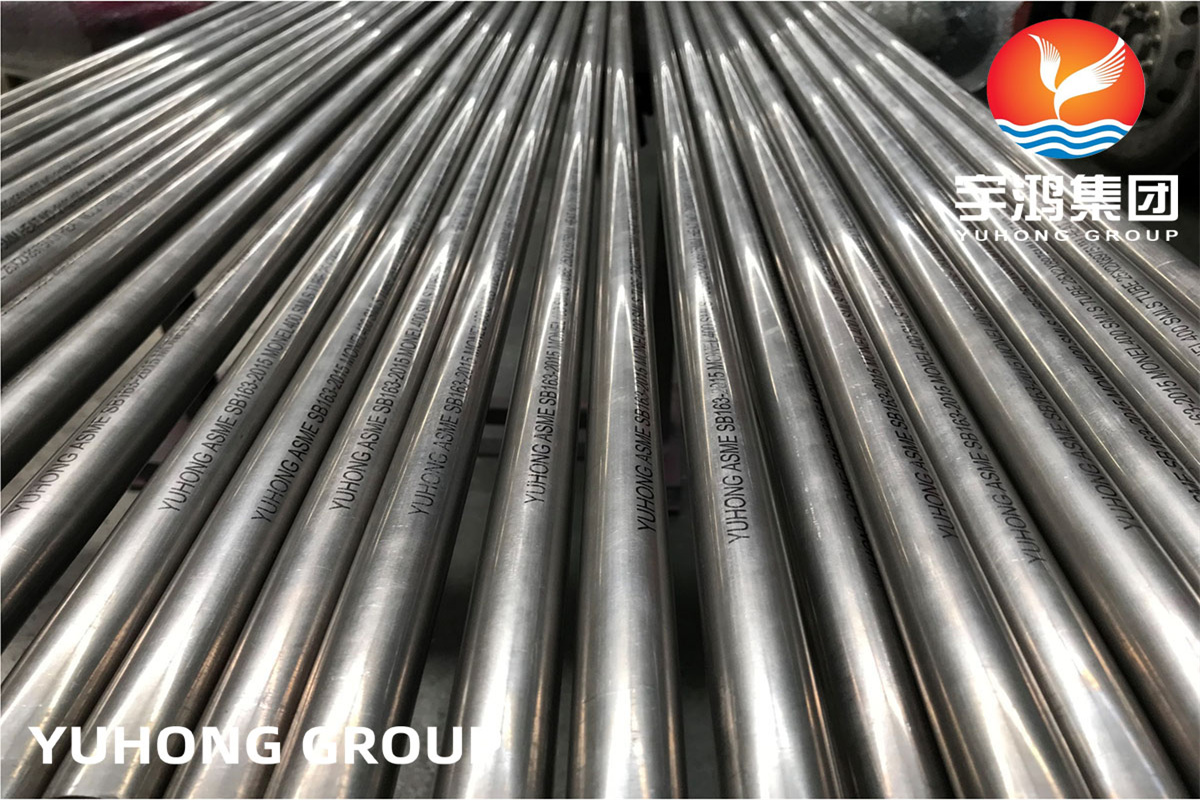

304 stainless tube and 316 are both codes for stainless steel. In essence, they have no difference and are both stainless steel, but they belong to different categories when divided into specific types. The quality of 316 stainless tube is higher than that of 304 stainless tube. 316 stainless tube incorporates molybdenum, which can further solidify the molecular structure of stainless steel, making it more wear-resistant and oxidation-resistant, and greatly enhancing its corrosion resistance. So what is the difference in their application scope?

Application scope of 304 stainless tube

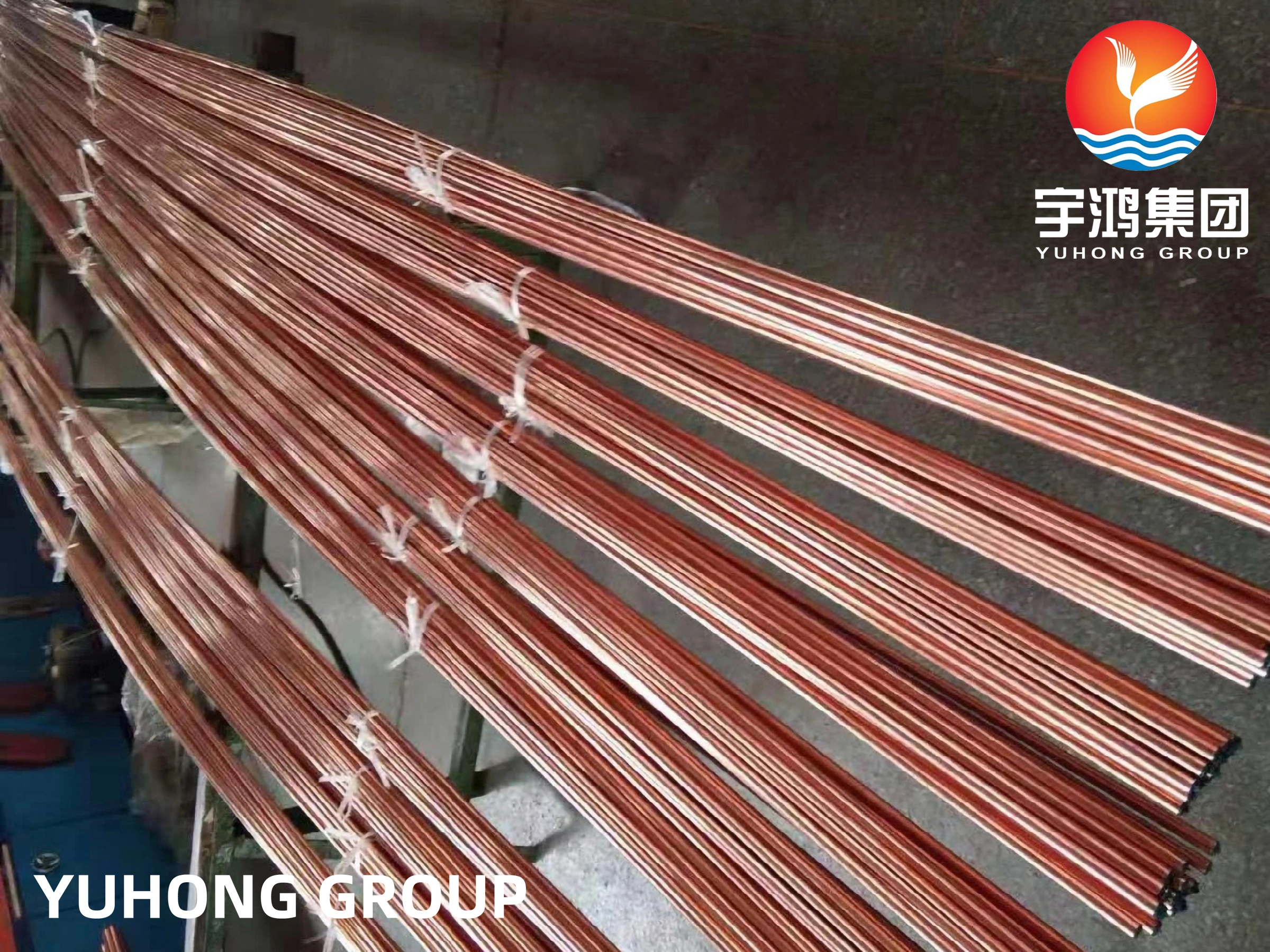

304 stainless tube is a widely used chromium-nickel stainless tube, which as a widely used steel, has good corrosion resistance, heat resistance, low-temperature strength, and mechanical properties. It has good thermal processing properties such as stamping and bending, and does not harden after thermal treatment. It is corrosion-resistant in the atmosphere, but if it is in an industrial atmosphere or heavily polluted area, it needs to be cleaned regularly to avoid corrosion. Suitable for decoration and construction (stainless steel anti-theft windows, stainless steel stair handrails, etc.), automotive parts (windshield wipers, mufflers, molded products), medical equipment, building materials, chemical, food industry, agriculture, ship components, etc.

The effect of using 304 stainless tube in dry indoor environment is quite good. However, in rural and urban areas, if you want to maintain its appearance outdoors, you need to clean it regularly. However, in industrially or oceanically corrosive environments, 316 stainless tubes are used.

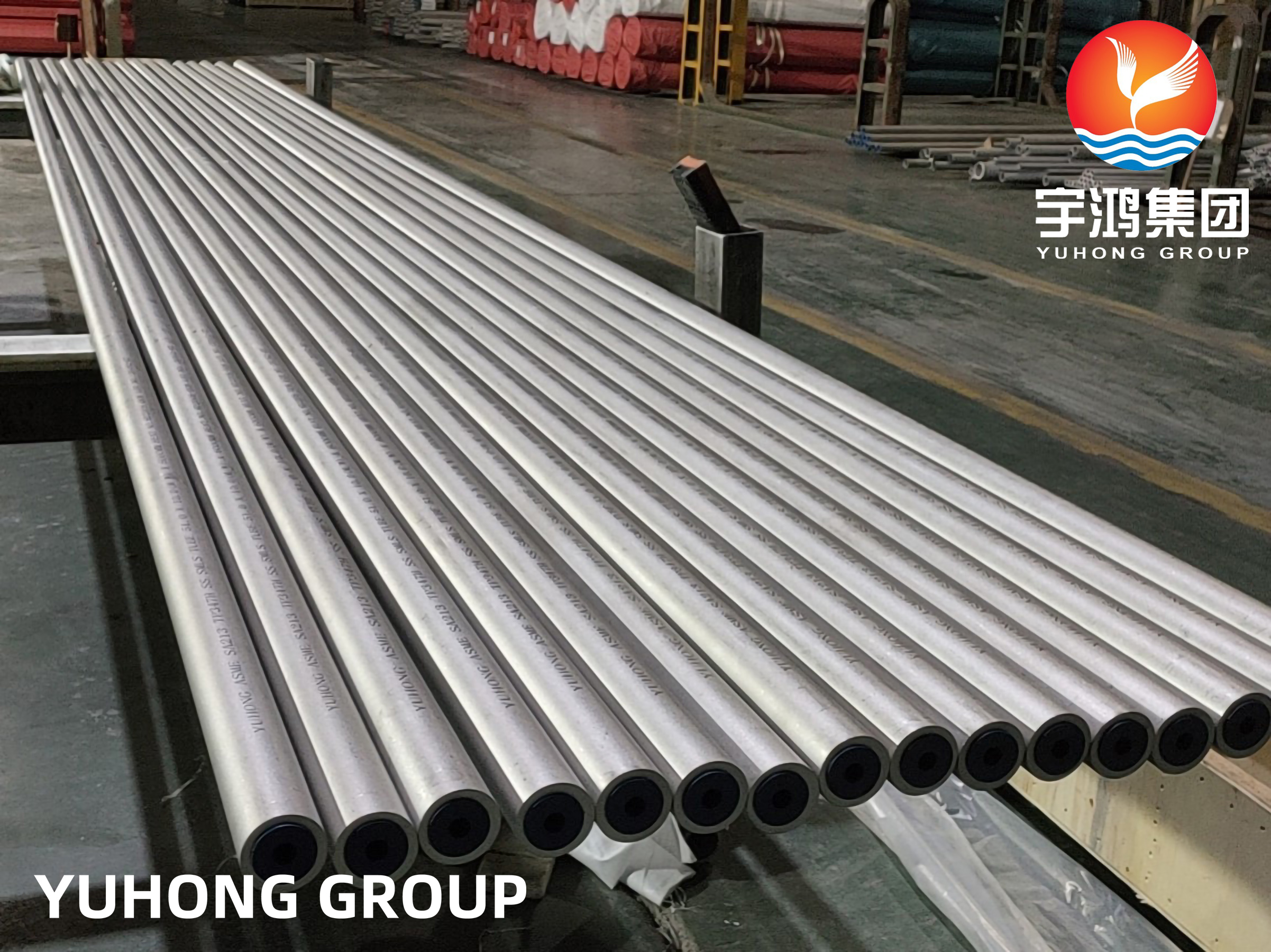

Application scope of 316 stainless tube

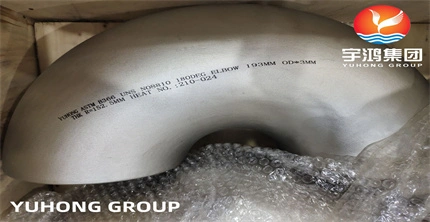

316 stainless tube is a steel material that is superior in corrosion resistance and other performance aspects compared to 304 materials. It is mainly used in industrial pipeline transportation such as petroleum, chemical, medical, food, mechanical instruments, and CNC processing, facilities in coastal areas, and production equipment in the sea due to the high salt content in the environment. 316L materials are also needed. In addition, it is widely used in industries such as chemical, construction, bridge, aerospace, machinery hardware, medical, decoration, fitness equipment, furniture, tableware manufacturing, liquid transportation, automobile manufacturing, water supply, solar energy, machinery manufacturing, nuclear power, building decoration, rail transit, sanitary ware, metal products, and container.

When we purchase stainless steel decorative pipes, the environment in which the stainless steel decorative pipes are used determines their service life, and the composition, temperature, and pressure of the corrosive medium are important factors to consider when choosing the appropriate stainless tube.

English

English