The welding process of stainless steel seamless pipe step 1: remove the weld seam

The weld seam can be removed by using a flip disc, light disc, or quick-change cloth disc. The selection depends on the type of stainless steel seamless pipe grinding machine and the expected life of the disc. Flap and fiber discs can be used for electric and pneumatic right-angle grinders, while cloth discs are only used for pneumatic high-speed vertical spindles.

Like other difficult-to-grind materials, stainless steel thin-walled seamless steel pipes require clear particles and continuous lubrication during the grinding process. For these reasons, ceramic alumina with a super-large coating or abrasive as a lubricant is recommended by professional we stainless steel pipe manufacturer as the grinding material.

Ceramic alumina has a microcracking ability that can continuously provide new cutting edges. Zirconia alumina or alumina oxide is also suitable for stainless steel, but ceramic alumina's properties provide more effective grinding, faster cutting speeds, and higher utilization rates per grain. In addition, abrasives can slow down the speed and, in some cases, eliminate disk loads, thus extending the product life.

The welding process of stainless steel seamless pipe step 2: align the line

The key part of the second step of stainless steel seamless pipes and tubes is to generate orientation scratches that match the original pattern direction. Regarding stainless steel plate processing, the operator confirms the stretching direction; for stainless steel thin-walled seamless steel pipes, the commonly used method is to grind parallel to the weld seam.

The equipment selection includes horizontal axis machines such as a drum-type sanding machine with a coated sanding belt; a high-speed pneumatic mold grinder with a flap wheel; and a pneumatic grinder with a non-woven wheel. The belt has speed and mixing functions. Ceramic alumina has the same cutting speed and life advantages, making it the particle in step 1. The recommended abrasive particle size is 100 to 120. Note that drum-type sanding machines are suitable for straight lengths. When the part equipment includes twisted, flared ends, and other curved features, it is recommended to use non-woven wheels of alumina oxide with a particle size of 80 or coarse sand.

The welding process of stainless steel seamless pipe step 3: do some surface treatment

For the latter step, it is recommended to use the equipment used in step 2, which is equipped with non-woven abrasive. The non-woven belt is composed of a strong synthetic mesh and abrasive, bonded by an adhesive. The open structure and buffering effect of the non-woven fabric can achieve a positive cutting effect and improve the surface smoothness in the absence of load.

Mixing is achieved by slowing down the sanding machine speed and stacking the welding area on the original pattern. Like step 2, the shape or size of the part may not allow the use of a belt sander. In this case, non-woven fabric grinding wheels with the same abrasive and particle size can be used to produce the desired smoothness.

If stainless steel seamless pipes require higher surface treatment, non-woven fabric medium with finer grit size can be used for adjustment. In some cases, it can also be changed to silicon carbide.

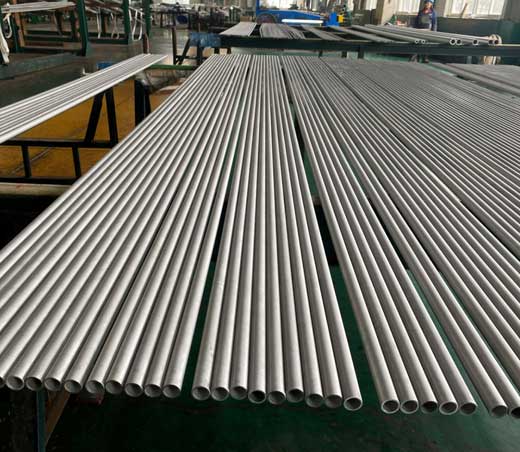

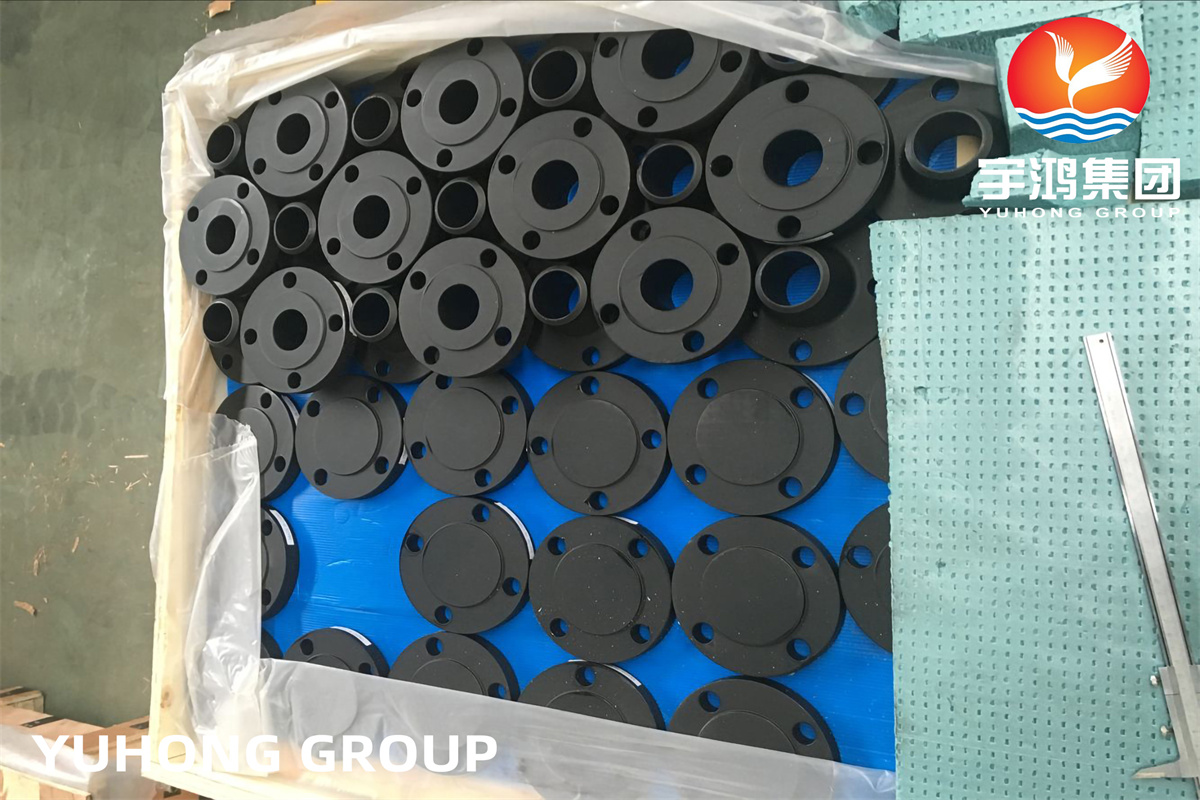

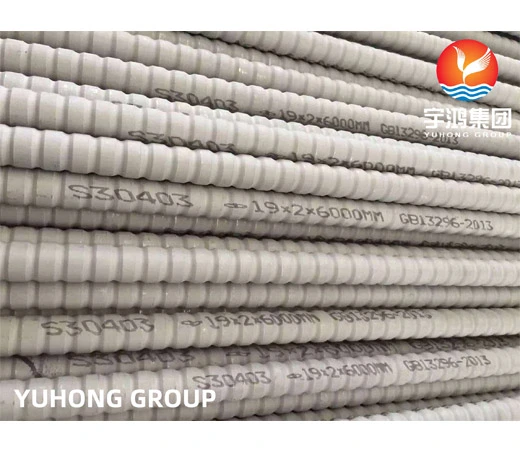

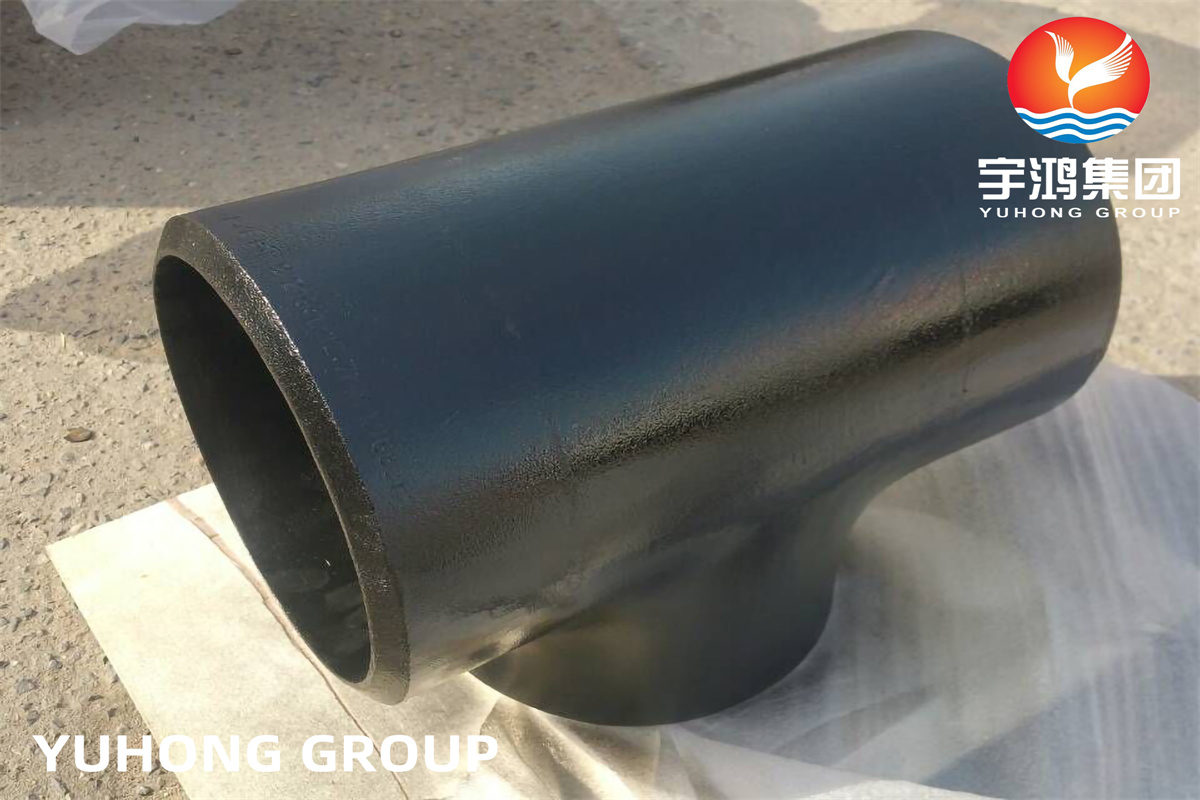

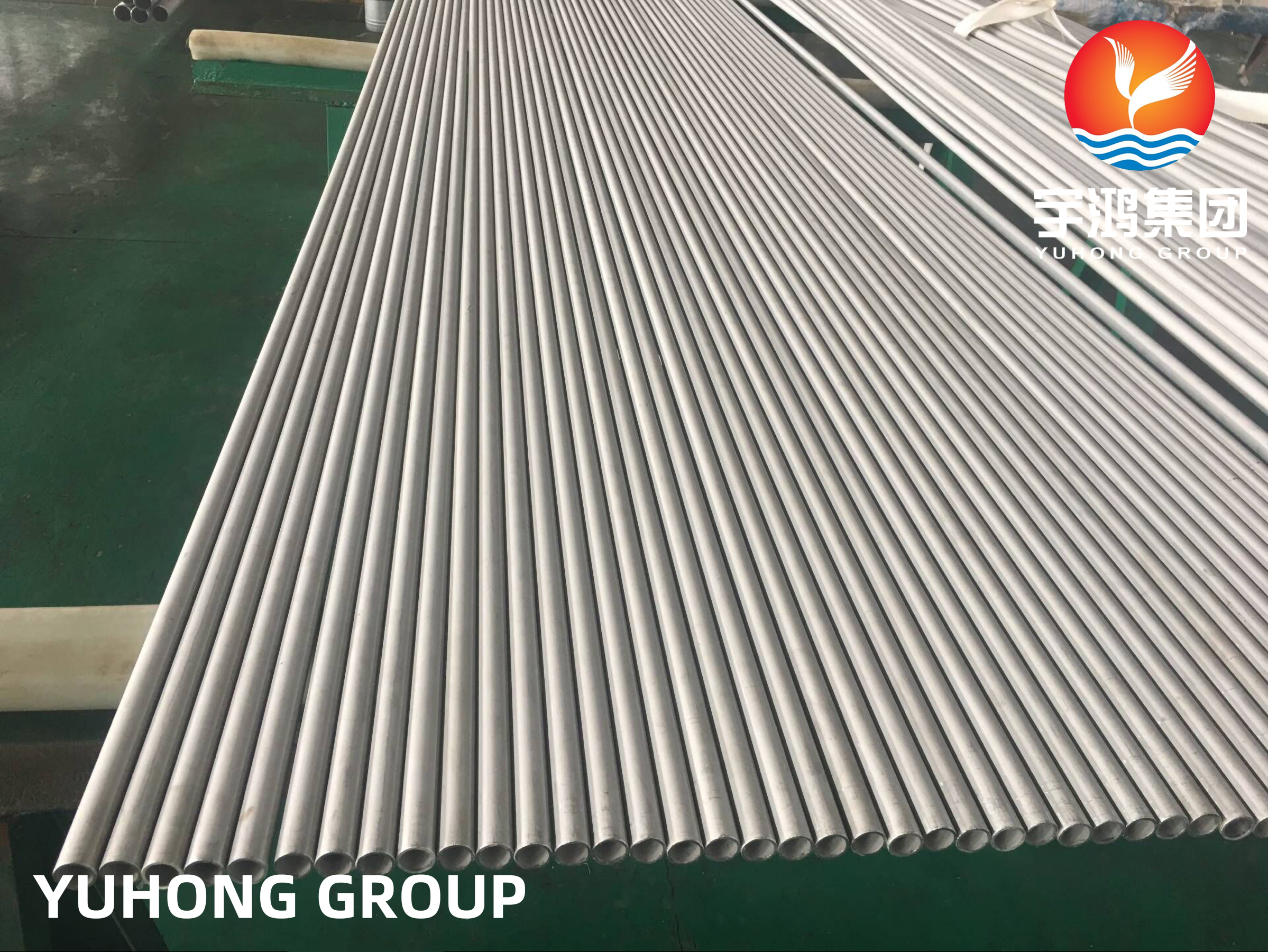

If you are interested in stainless steel seamless pipes and tubes, you can learn about the following products of Yuhong:

astm a213 stainless steel tube/asme sa213

tp304l seamless tube

tp316l stainless steel pipe

tp 347h pipe

English

English