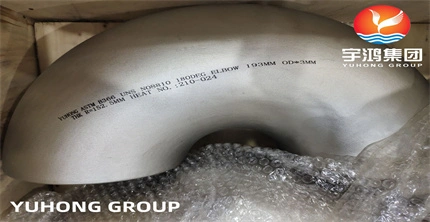

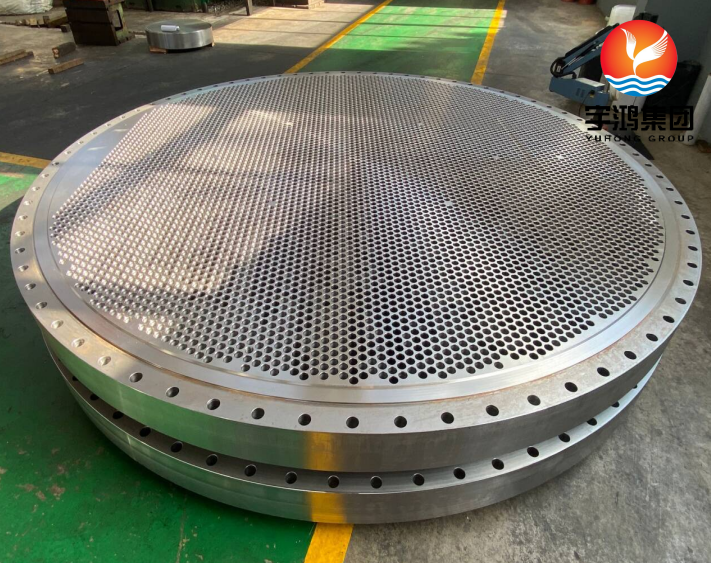

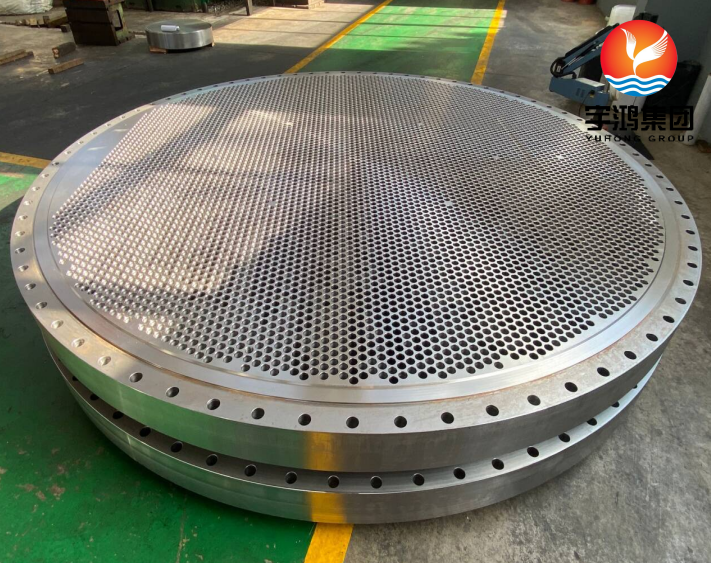

YUHONG can offer stainless steel, carbon steel, copper steel and other material tubesheet.

Controlling welding deformation of pressure vessel tube plates is an important issue in the manufacturing process of pressure vessels, because the welding process will cause tube plates to deform, which in severe cases will affect the performance and safety of the pressure vessel. Therefore, controlling tubesheet welding deformation is a key step to ensure welding quality and mechanical properties of pressure vessels. Yuhong Group, a seasoned supplier of pipe plates, is here to share you some ways to control welding deformation.

Tubesheet welding deformation mainly includes linear deformation and area deformation.

Linear deformation refers to the displacement perpendicular to the coal seam in the direction of the weld axis in the weld and its surrounding area, which mainly manifests as bending, twisting, etc.

The area deformation refers to the distance between the weld and its surrounding area along the axis of the weld that becomes longer or shorter after welding, which is mainly manifested as shrinkage,etc.

Some Methods to Control Welding Deformation

1. Welding sequence optimization

-Selecting the appropriate welding sequence can reduce tube sheet welding deformation. Usually, alternating welding from the center to every other week or from the edge to the center is a common welding sequence.

2. Adopting welding deformation control technology

-Use preheating and post-heat treatment techniques. Preheating can reduce the temperature gradient during the welding process, and post-heat treatment can reduce the deformation of the tube sheet by controlling the cooling rate of the weld.

-Use layer-by-layer cooling method. In the multi-layer welding process, the deformation of the weld of the next layer can be reduced by locally cooling the weld of the previous layer.

3. Use welding auxiliary equipment

4. Properly designed structure and geometry

-When designing pressure vessels, a well-structured design can be adopted to avoid uneven dimensional heat input and deformation.

-Try to avoid or reduce the length and width dimensions of the tube sheet.

-Local strengthening structures can be used to reduce tube-sheet welding deformation.

5. Control welding parameters

- Optimize welding parameters such as welding current, voltage, speed, etc. to reduce heat input and welding deformation during welding.

In short, controlling the welding deformation of pressure vessel tube sheets is a complex issue that requires comprehensive consideration of multiple factors such as welding sequence, welding deformation control technology, welding auxiliary equipment, structural design, and welding parameters.

.jpg)

.jpg)

English

English

.jpg)

.jpg)