Duplex stainless steel is a high-end product in the stainless steel industry. Duplex steel outperforms ordinary stainless steel in terms of strength and corrosion resistance, and is mainly used in energy, chemical, petrochemical, freshwater manufacturing, pulp and papermaking, chemical shipping, and other industries.

How the deformation of duplex steel bends occurs?

Duplex steel is widely used in many industries. Here we discuss the issue of deformation of duplex steel bends and how to deal with it.

Turn straight pipes into bends with different radii, such as stainless steel bends;

Flange the pipe end to form raised or grooved fittings around the circumference of the pipe;

Change the cross-section of the pipe to meet requirements, such as turning round sections into square, elliptical, polygonal, etc.;

With a flanged edge and sealed tube end, increase the overall strength of the pipe by rolling the edge or sealing the end of the fitting inside or outside;

Change the thickness of the wall along the length of the pipe, making it a thick-walled bend.

Applications and advantages of duplex steel pipes

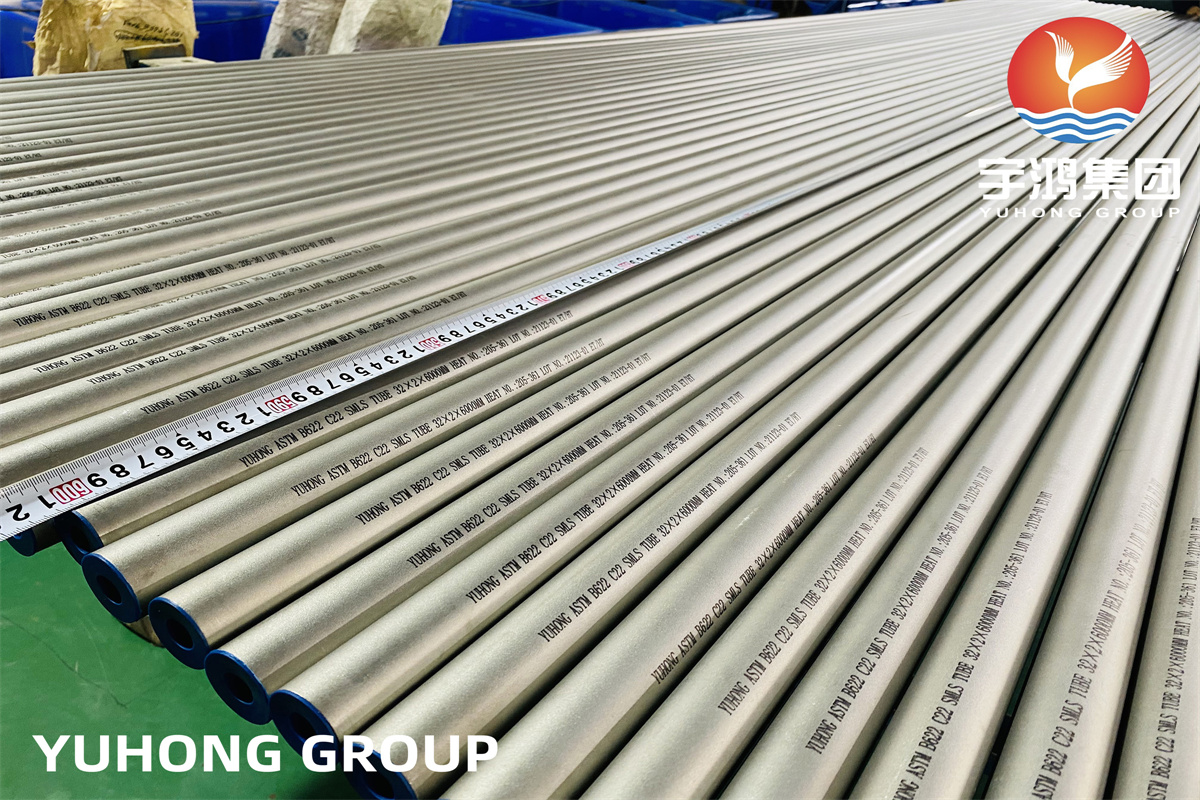

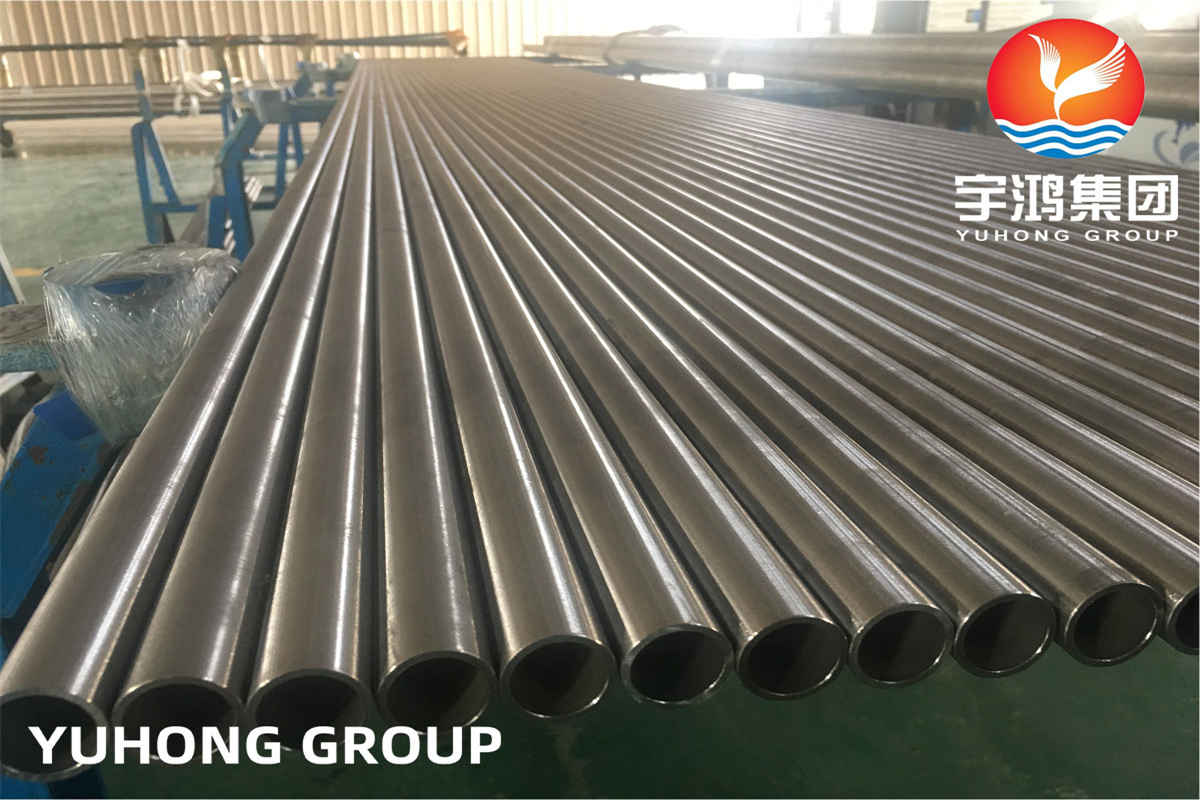

Duplex steel pipes are a type of stainless steel pipe fittings made from duplex steel. They include duplex steel bends, tees, crosses, reducers, and caps. According to the connection method, they can be divided into four categories: socket-type, threaded, flanged, and welded duplex steel pipes. Duplex steel bends are used for turning pipe fittings; flanges are used for mutual connection between pipelines at the pipe end; tees are used at the intersection of three pipes; crosses are used at the intersection of four pipes; reducers are used to connect pipes of different diameters. Duplex steel pipes are a general term for all kinds of duplex steel pipe connection fittings, which can be classified into different categories according to their shapes, uses, and connection methods. They are easy to install, have high performance, and are durable, and are widely used in various pipeline construction and installation.

Duplex steel pipe fittings can be divided into duplex steel tees, flanges, caps, bends, reducers, and end caps.

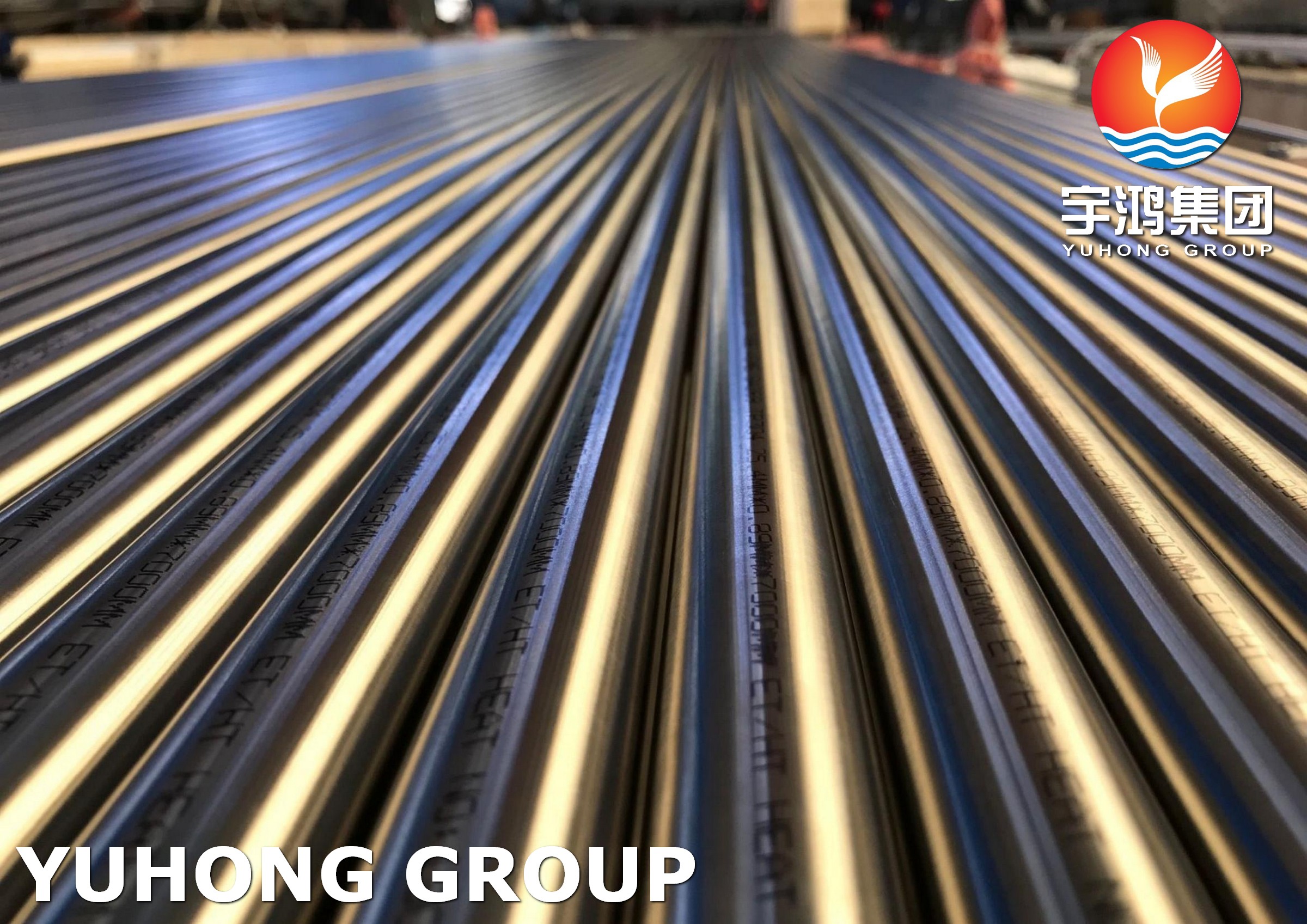

Thanks to their dual-phase microstructure, duplex steel pipes combine the best properties of austenitic and ferritic stainless steels. This results in fittings that are not only easy to install but also boast superior strength, enhanced corrosion resistance, and extended durability. Their high performance makes them an ideal choice for a broad spectrum of pipeline construction and installation projects across various industries.

The versatility and advantages of duplex steel pipe fittings make them a preferred option for modern piping systems. For those in the industry, sourcing these components from a reputable stainless steel tubes manufacturer ensures that your pipeline infrastructure benefits from the highest quality materials available. This not only guarantees the longevity and reliability of the system but also enhances safety and efficiency in operations.

Welding methods for duplex steel pipes

Duplex steel pipe fittings are the most reliable connection method, where the duplex steel pipe is inserted into the socket of the fitting and then argon arc welded along the edge of the fitting. The inner diameter of the socket is equal to the outer diameter of the pipe. Depending on the welded edge parts of the fitting, they can be divided into three types: sloped edge joint, stepped edge joint, and non-joint fittings.

Butt-welding duplex steel pipe fittings are made by welding duplex steel pipes and fittings along the butt joint with a circle of argon arc welding. Generally, it requires welding. The outer diameter of the socket is equal to the outer diameter of the pipe. Butt-welding is generally used for welding larger-scale two-phase steel pipe systems.

English

English