In recent years, with the rapid development of social economy, 304 stainless steel water pipes are becoming more and more common in our daily life. There are many connection methods for 304 stainless steel water pipes, including flexible type, clamp type, flange type, compression type, etc. So which way is better for our family to use stainless steel water pipes? Which is more reliable? Let's take a look together below.

Ⅰ. Advantages of 304 stainless steel pipe

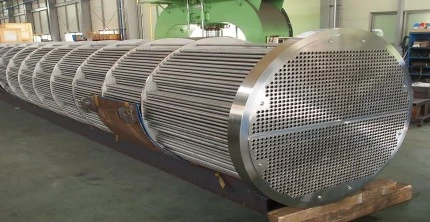

304 stainless steel pipe is a versatile stainless steel, which is widely used in the production of equipment and parts that require good overall performance (corrosion resistance and formability). 304 stainless steel pipe is a grade of stainless steel produced according to the American ASTM standard. 304 is equivalent to 0Cr18Ni9 stainless steel. 304 contains 18% chromium and 9% nickel. 304 is the most widely used stainless steel, used in food production equipment, general chemical equipment, nuclear power, etc.

304 stainless steel pipes are widely used in industries such as food equipment, general chemical equipment, and atomic energy industry equipment components, and are suitable for deep drawing parts, acid pipelines, containers, etc. It is the most produced and used steel among austenitic stainless steels. It is used in the production of thin-walled parts, acid pipelines and structural parts, etc. It is also often used as a core material for welding chromium-nickel stainless steel and stainless steel, non-magnetic parts and low temperature environments. parts etc. The most important elements of 304 stainless steel pipes are Ni and CR, which are widely used in industry and food and medical industries. 304 stainless steel is the most common material. It is resistant to high temperature and can be used in bathrooms, kitchens and coastal wet areas, which is the advantage.

Ⅱ. The connection method of 304 stainless steel pipe

1. Flexible connection

The method of flexible connection of 304 pipe is to insert the pipe into the nozzle of the pipe fitting, tighten the nut with a wrench, use the compression ring to seal the sealing ring, and then complete the connection; its feature is that it is easy to install and can be disassembled at will. However, the installation conditions must use the groove machine to roll the groove on the end of the pipe to fix the C-shaped groove.

2. Compression connection

The method is to insert the pipe into the connecting pipe of the pipe fitting, tighten it with a nut, and use the screw force to compress and seal the casing of the connecting pipe through the sealing ring and complete the connection; it is characterized by fast installation and detachable, but the connection reliability is relatively weak The threads are easy to loosen, causing the nuts to be tight. When the pressure of the seal is reduced, leakage will occur. The parts with complex structures are expensive and cannot be buried.

3. Flange connection

Principle: Argon arc welding between the flange and the pipeline, fastened with quick clamps or bolts, and gaskets between the flanges.

4. Single card press connection

The method is to insert the accessories into the accessories. The two ends of the accessories are protruding U-shaped grooves with built-in sealing rings, and are pressed and connected by a special accessory tool to insert the parts.

5. Double card press connection

304 pipe double clamping connection is an improved S-type clamping connection technology based on single clamping connection technology; features: easy and quick installation, reliable sealing, shockproof, avoid loose joints, short installation period, low cost, it avoids the quality defects caused by factors. The O-ring in the pipe fitting has a certain degree of elasticity after compression, and automatically compensates after thermal expansion and cold contraction to ensure the safety of the pipeline. The diameter of the clamping connection is less than or equal to 100 mm.

English

English