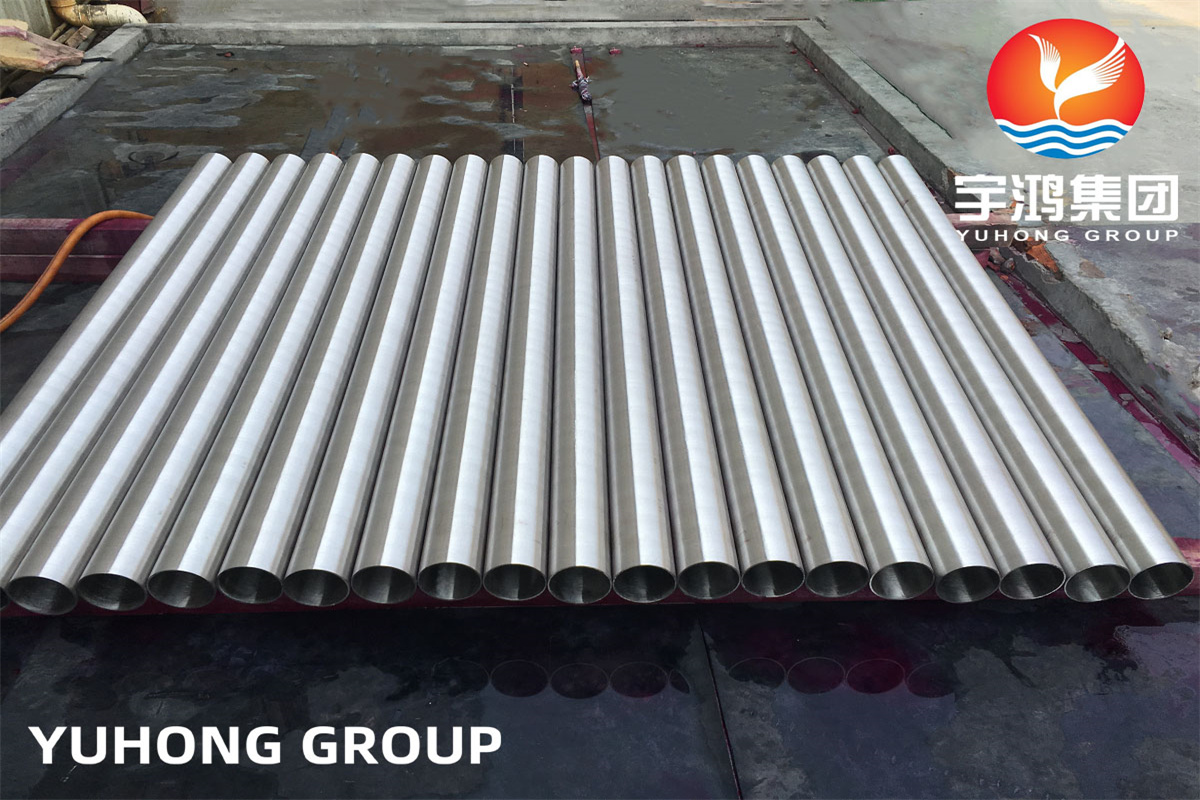

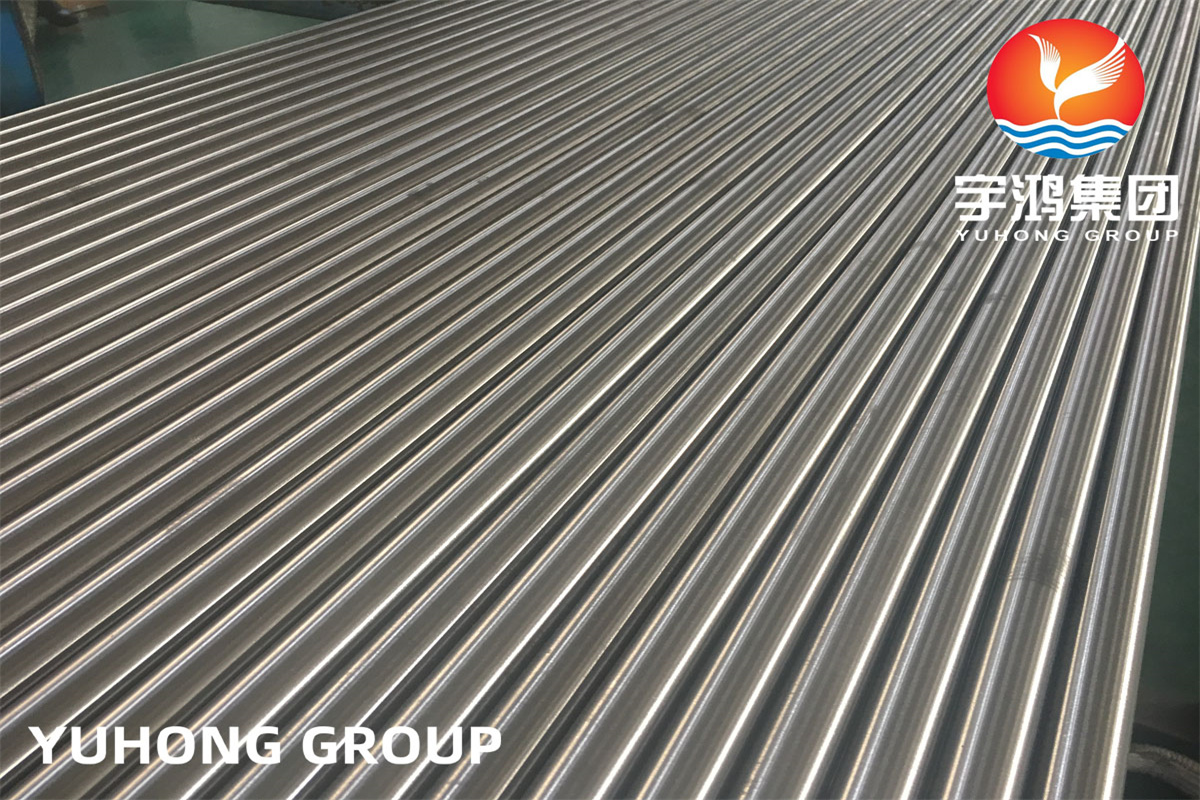

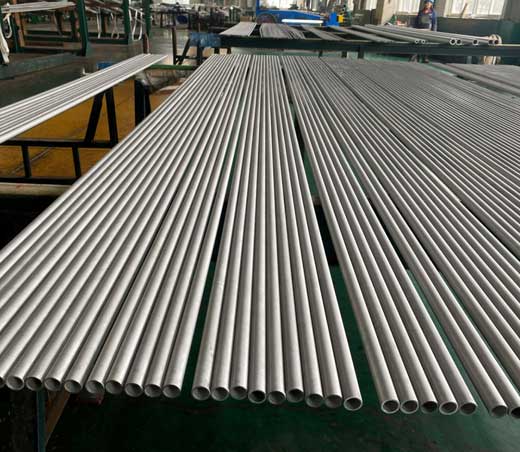

Stainless steel pipe is a kind of hollow long strip circular steel, mainly widely used in petroleum, chemical industry, medical, food, light industry, machinery and instrument industry, industrial pipeline and mechanical structural components. In addition, it is also widely used in the manufacture of machinery parts and engineering structures due to its lighter weight when bending and torsional strength are the same. It is also commonly used in furniture and kitchenware.

SS pipes are divided into ordinary carbon steel pipes, high-quality carbon structural steel pipes, alloy structural pipes, alloy steel pipes, bearing steel pipes, SS pipes, as well as bimetal composite pipes, coating and coating pipes, in order to save precious metals and meet special requirements. The types of SS pipes are numerous, with different uses, different technical requirements, and different production methods. The current production range of steel pipes is 0.1-4500mm in outer diameter and 0.01-250mm in wall thickness. In order to distinguish its characteristics, steel pipes are usually classified by the following methods.

Classification of SS pipes according to production methods

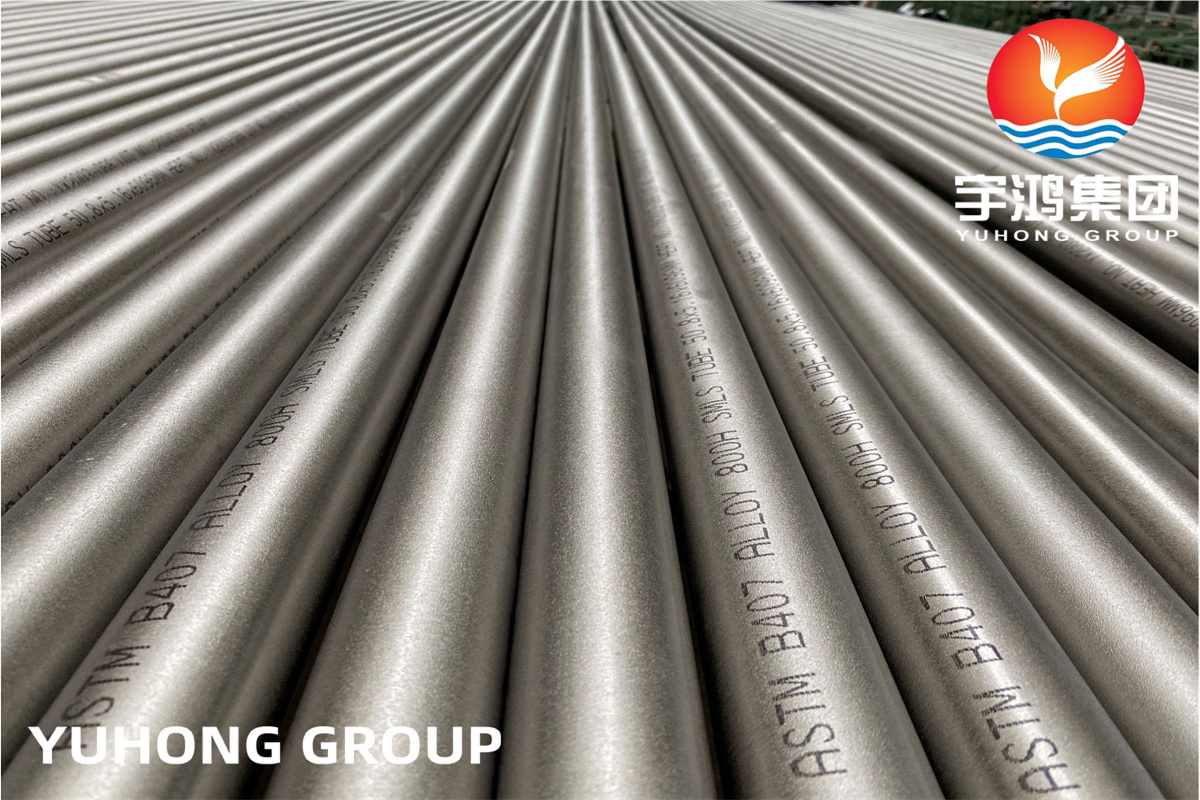

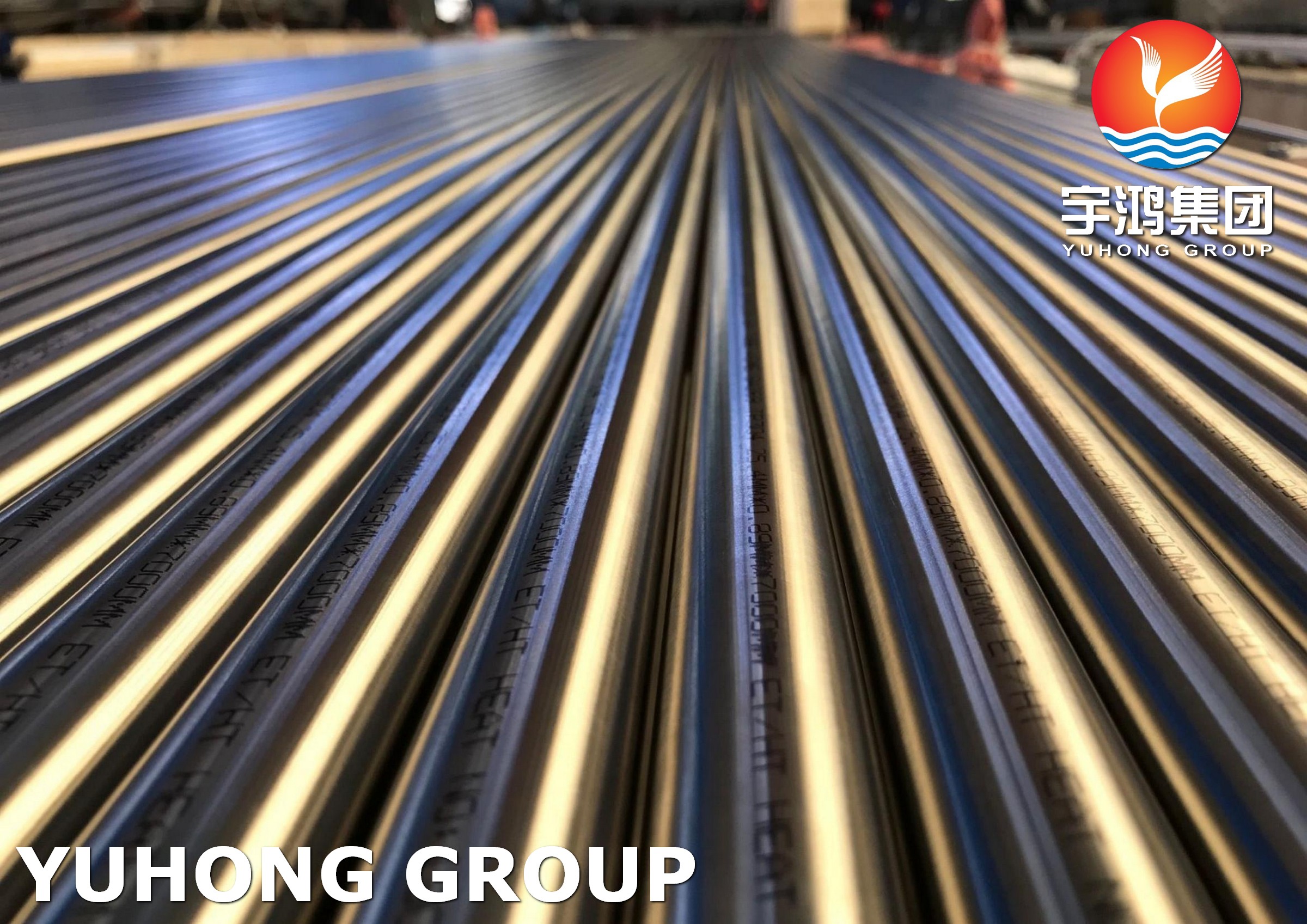

Stainless steel pipes are divided into seamless pipes and welded pipes according to production methods. Seamless steel pipes can be divided into hot-rolled pipes, cold-rolled pipes, cold-drawn pipes, and extruded pipes. Cold-drawing and cold-rolling are the secondary processing of steel pipes; welded pipes include straight seam welded pipes and spiral welded pipes.

Classification of SS pipes according to cross-sectional shape

Stainless steel pipes can be divided into round pipes and special-shaped pipes according to their cross-sectional shapes. Special-shaped pipes include rectangular pipes, diamond-shaped pipes, elliptical pipes, hexagonal pipes, octagonal pipes, and various sectionally asymmetric pipes. Special-shaped pipes are widely used in various structural components, tools, and mechanical parts. Compared with round pipes, special-shaped pipes generally have larger moments of inertia and cross-sectional modulus, larger bending and torsional resistance, and can greatly reduce structural weight and save steel.

Stainless steel pipes can be divided into equal-section pipes and variable-section pipes according to their longitudinal cross-sectional shapes. Variable-section pipes include conical pipes, stepped pipes, and periodic section pipes.

Classification of SS pipes according to pipe end shapes

Stainless steel pipes can be divided into bright pipes and threaded pipes (threaded steel pipes) according to the pipe end states. Threaded pipes can be divided into ordinary threaded pipes (used for low-pressure pipes such as water and gas, with ordinary cylindrical or conical pipe threads) and special threaded pipes (used for petroleum and geological drilling pipes, special threads are used for important threaded pipes). For some special-purpose pipes, in order to compensate for the influence of threads on the end strength of the pipe, the pipe ends are usually thickened before threading (inner thickened, outer thickened or inner and outer thickened).

Classification of SS pipes according to applications

Stainless steel pipes can be divided into oil well pipes (casing pipes, oil pipes, and drill pipes, etc.), pipeline pipes, boiler pipes, mechanical structural pipes, hydraulic pillar pipes, gas cylinder pipes, geological pipes, chemical pipes (high-pressure fertilizer pipes, petroleum cracking pipes), and ship pipes according to their applications.

English

English