This 310S coil tubing for sale is an element of the tubular cylindrical furnace of the hydrogenation unit.

The product goes to the coil inlet from the heat exchanger, and the product goes to the reactor from the coil outlet. The tubular cylindrical furnace is a critical piece of equipment in a hydrogenation unit, providing the precise and controlled heat required to drive the chemical reactions.

_副本.jpg)

Key Design Features

1.Cylindrical Shape: This shape is mechanically strong, efficient to construct, and provides excellent radiant heat distribution.The furnace itself is a vertical, cylindrical steel structure.

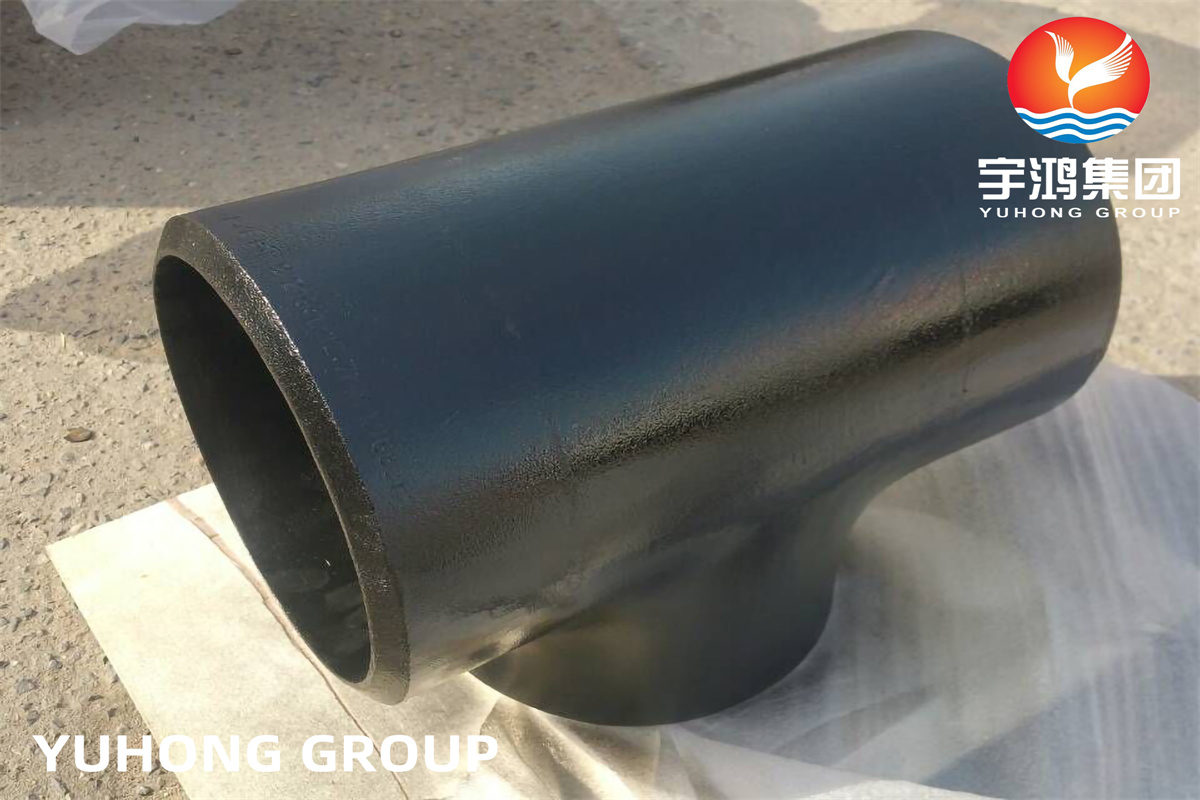

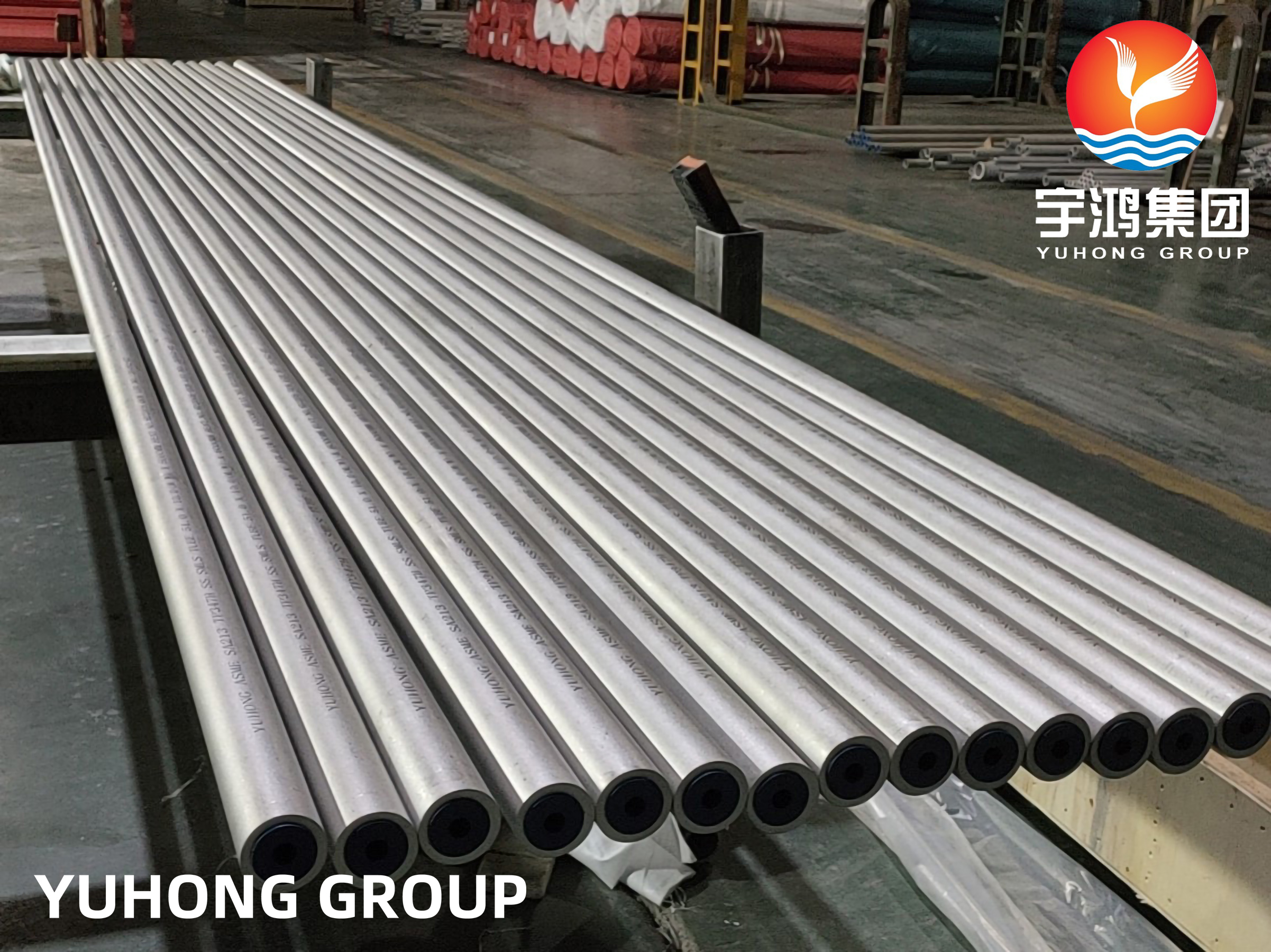

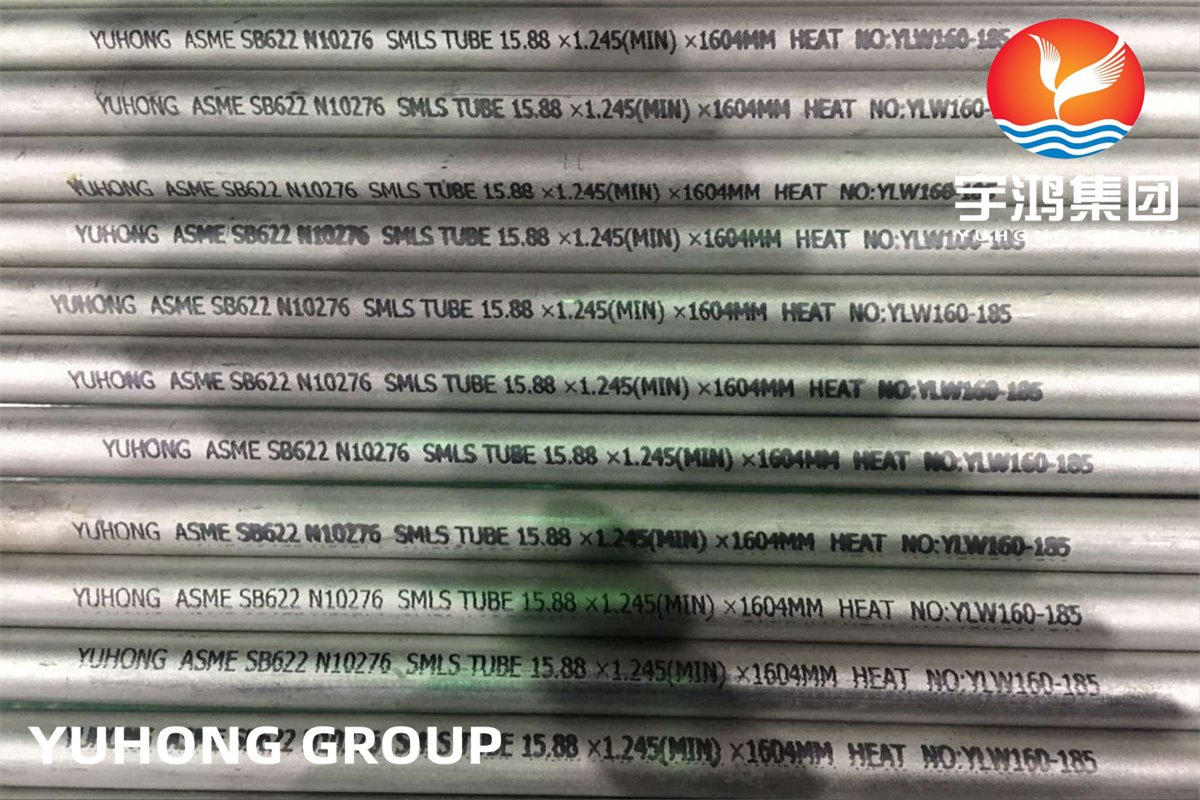

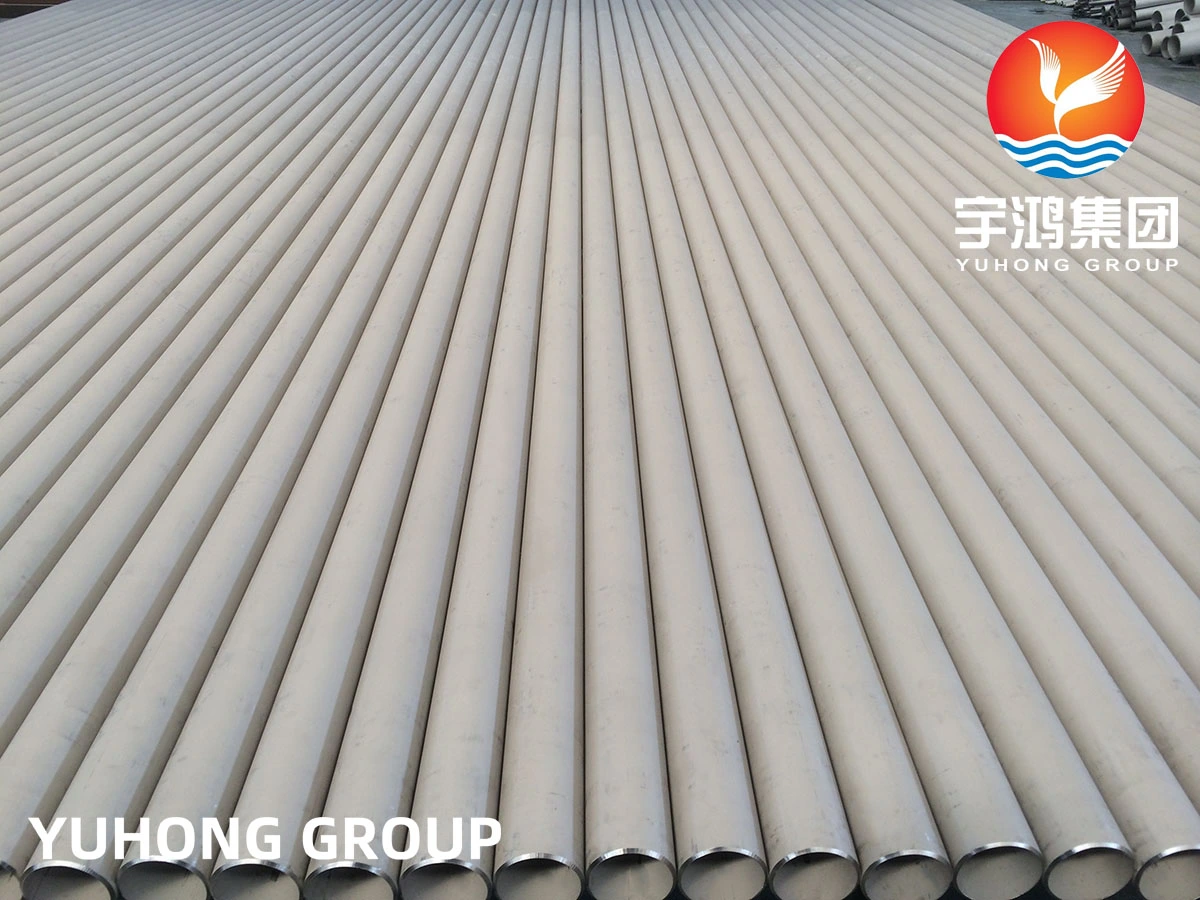

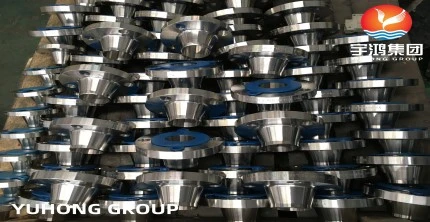

2. Tubular Heating Coils: Inside the furnace, the process fluid (the mixture of oil and hydrogen) flows through a series of long, continuous pipes arranged in a coil configuration. These coils are made from high-grade alloy steel or stainless steel (e.g., ASTM A335 P5/P9, 321SS, 347SS,310SS) to withstand high temperatures, high pressures, and the corrosive environment of hydrogen and sulfur.

3. Burners: Located at the bottom (floor-fired) or along the walls (wall-fired) of the furnace. They provide the heat by combusting a fuel gas, which is often a purge or off-gas stream from the process itself, making the unit more energy-efficient.

4. Refractory Lining: The interior walls of the cylindrical shell are lined with several layers of special refractory (ceramic) insulation and brickwork. This contains the intense heat within the furnace, protects the steel shell, and ensures maximum efficiency by minimizing heat loss.

Advantages in Hydrogenation Service

1.High Efficiency: The cylindrical design and convective section effectively transfer heat from flue gases.

2.Uniform Heating: The arrangement of tubes and burners can be designed for even heat distribution, which is crucial for preventing hot spots.

3.Handles High Pressure: The tube-in-coil design is excellent for containing the high pressures typical of hydrogenation processes.

4.Compact Footprint: A vertical cylindrical design has a smaller plot space requirement compared to a box-type furnace.

_副本.jpg)

English

English

_副本.jpg)

_副本.jpg)