Steel shell and tube heat exchangers are very commonly used in chemical production. Whether it is a fixed tube sheet, a floating head tube sheet, or a U-shaped shell and tube heat exchanger, the connection between the tube and the tube sheet is a very important structure in the heat exchanger.

The types of connection joints between the heat exchanger tube plate and the tubes are divided into expansion joints, welding joints, and expansion joints and welding joints according to the use conditions of the heat exchanger.

Expansion

First, put the pipe expander into the pipe to enlarge the diameter of the pipe, undergo plastic deformation, and fit tightly to the pipe plate. The tube plate in contact with the nozzle will also become larger as the nozzle becomes larger, resulting in elastic deformation.

When the tube expander is pulled out, the elastic deformation of the tube plate will return to its previous size, but the tube orifice after plastic deformation will still remain enlarged and will not return to its original shape, so that the two are tightly connected together.

Welding

Welding is divided into two types: strength welding and sealing welding.

When the heat exchange tube and the tube sheet are connected by welding, due to the low processing requirements for the tube sheet, simple manufacturing process, good sealing, and convenient welding, visual inspection, and maintenance, it is the current shell and tube heat exchanger. The most widely used connection method is the connection between the heat exchange tube and the tube sheet.

Expansion and Welding

When the temperature and pressure are high, and under the action of thermal deformation, thermal shock, thermal corrosion and fluid pressure, the connection between the heat exchange tube and the tube sheet is easily damaged, and it is difficult to ensure the connection strength and sealing using expansion joints or welding. requirements.

At present, the method of combined expansion welding is widely used. The expansion joint and welding structure can effectively prevent the damage to the weld caused by the vibration of the tube bundle, effectively eliminate stress corrosion and gap corrosion, improve the fatigue resistance of the joint, thereby increasing the service life of the heat exchanger, which is better than simple expansion joint or Strength welding has higher strength and tightness.

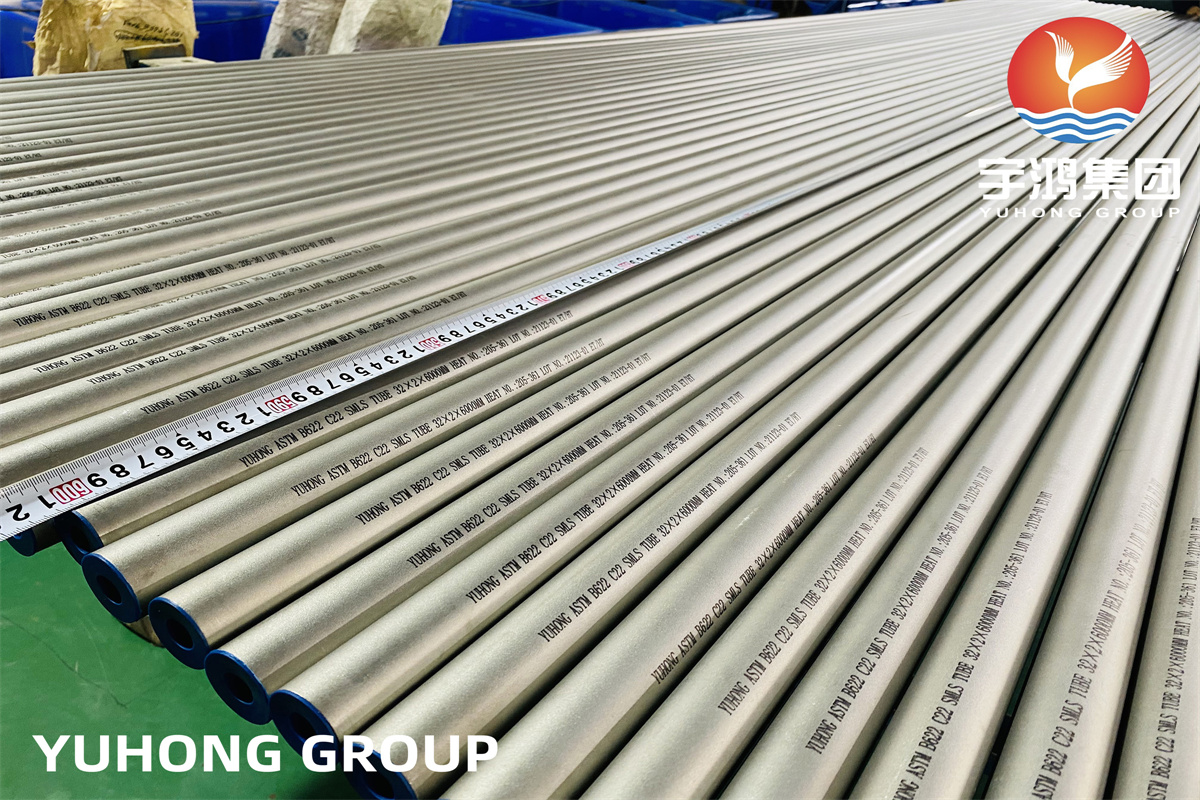

As an important structure in heat exchangers, heat exchanger tubes are crafted from a diverse range of materials, such as titanium alloy, copper alloy, stainless steel, etc., contingent upon the fluid being processed and operational parameters.

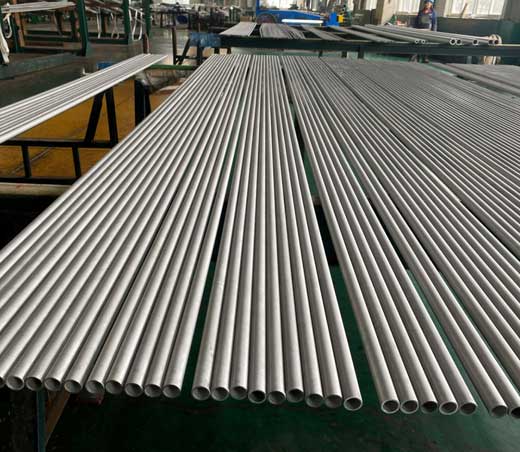

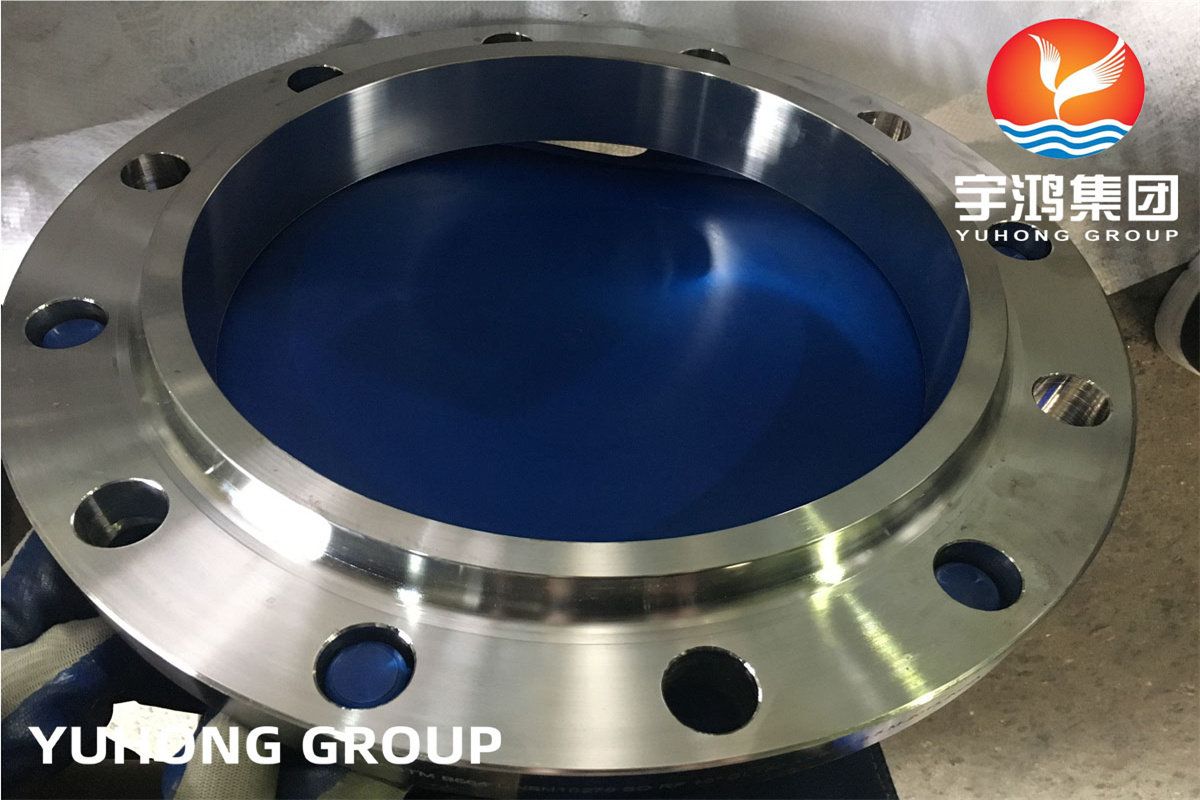

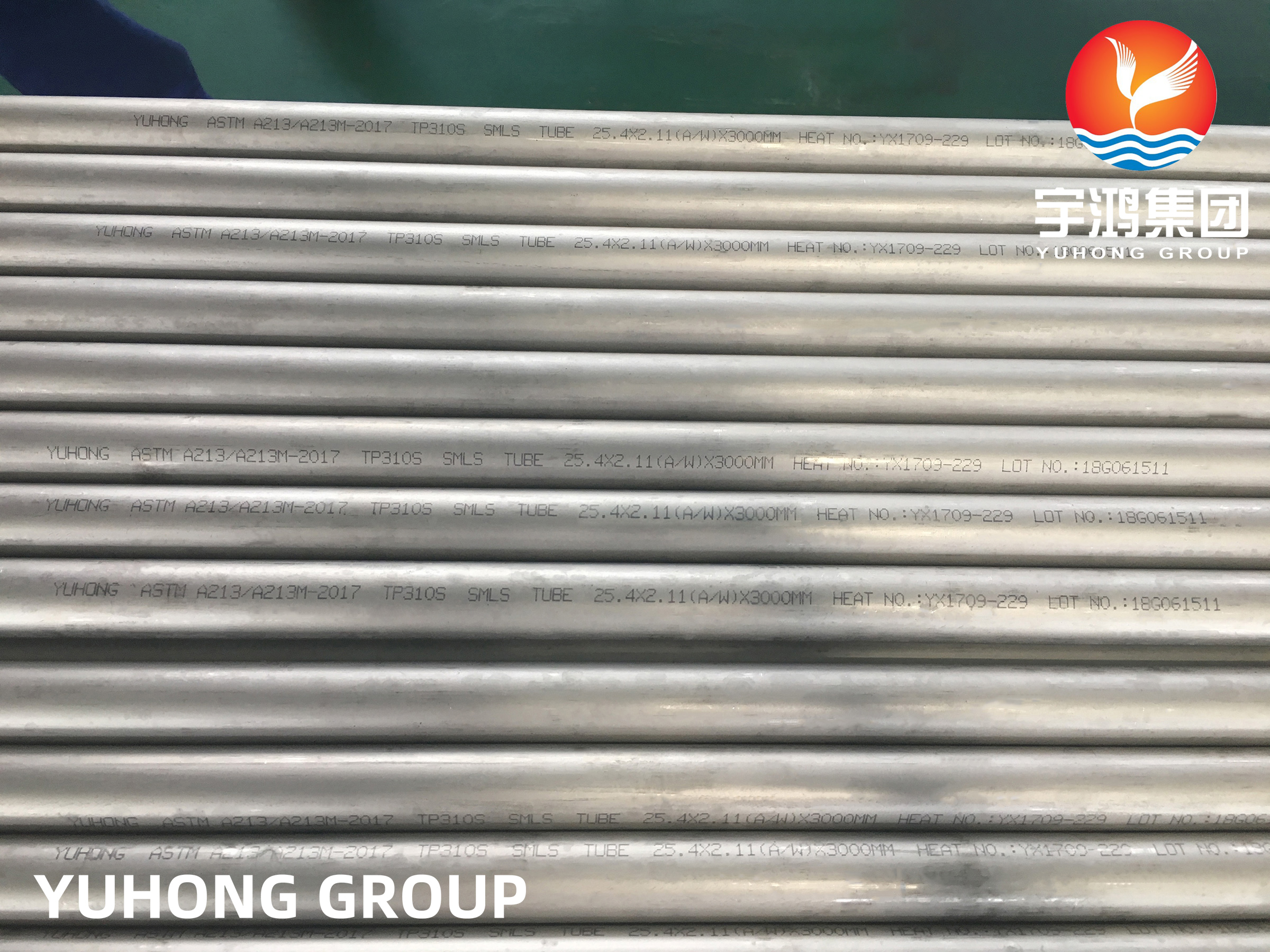

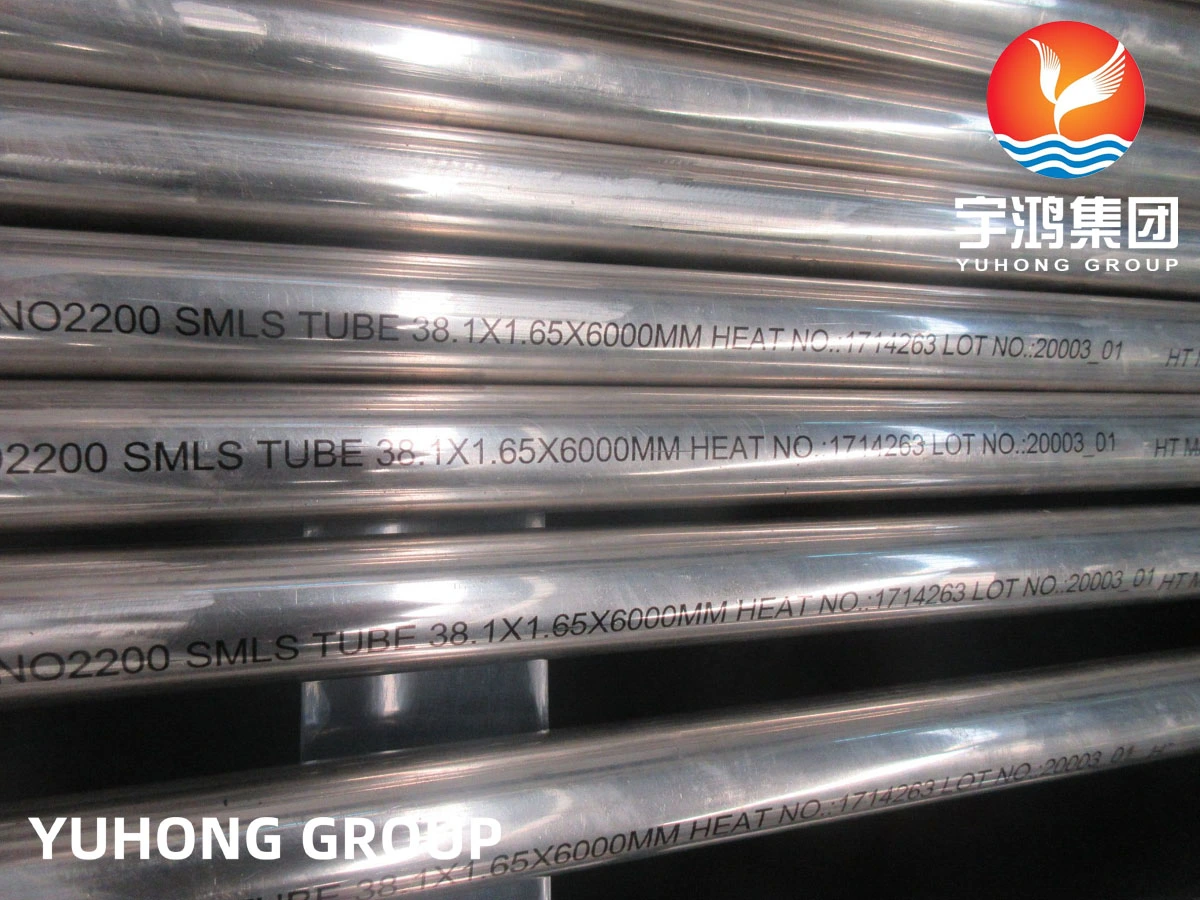

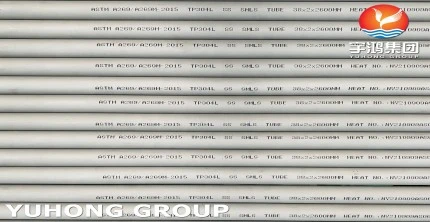

Yuhong Group, a professional heat exchanger tube manufacturer, offers seamless and welded tubes to meet the requirements for tube heat exchangers. For example:

astm a213 stainless steel tube/asme sa213

a249 stainless steel tube/asme sa249

astm a269 tubing/asme sa269

.jpg)

English

English

.jpg)