Inconel flanges have gained prominence in marine applications due to their exceptional corrosion resistance, high strength, and heat resistance. To maximize their longevity and performance in the challenging marine environment, proper maintenance is crucial. This blog explores key strategies and practices on how to maintain Inconel flanges for extended service life in marine applications.

Understanding the Benefits of Inconel in Marine Environments

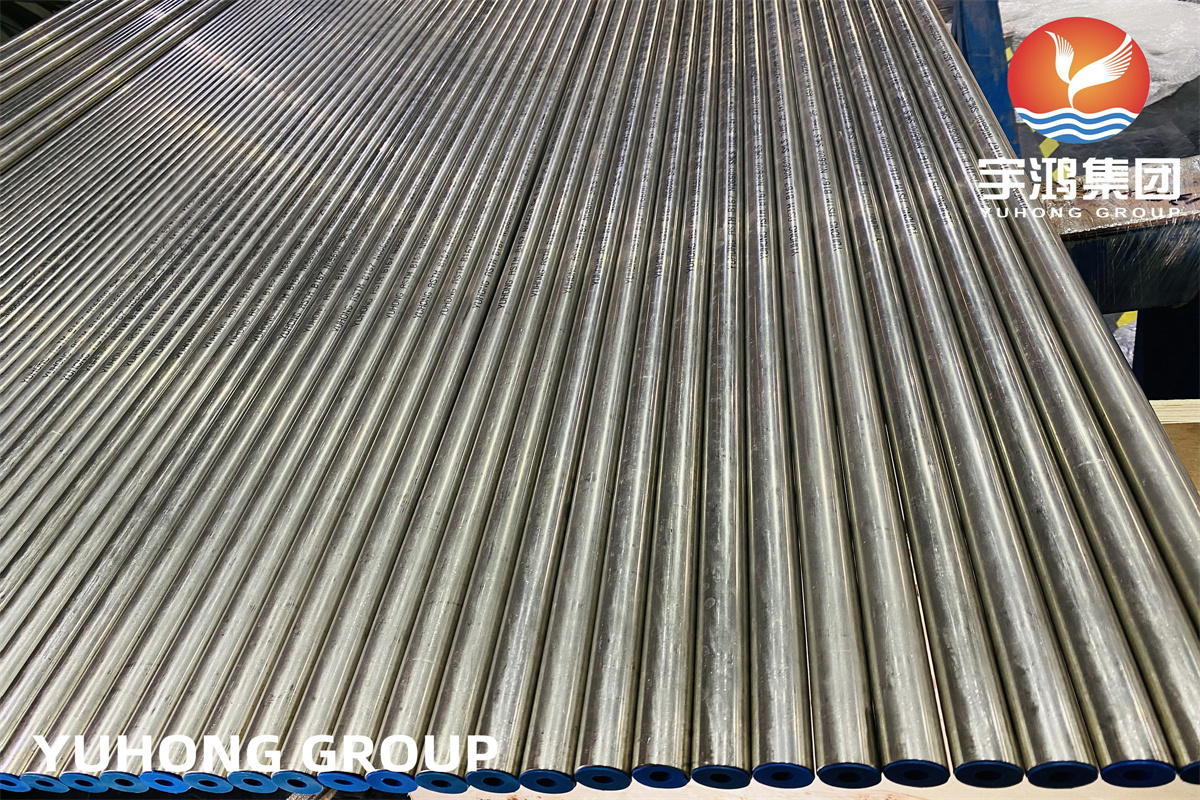

Corrosion Resistance

Inconel alloys, known for their resistance to corrosion and oxidation, are particularly well-suited for marine environments where exposure to saltwater and harsh weather conditions is inevitable. Proper maintenance ensures that this corrosion resistance remains intact over time.

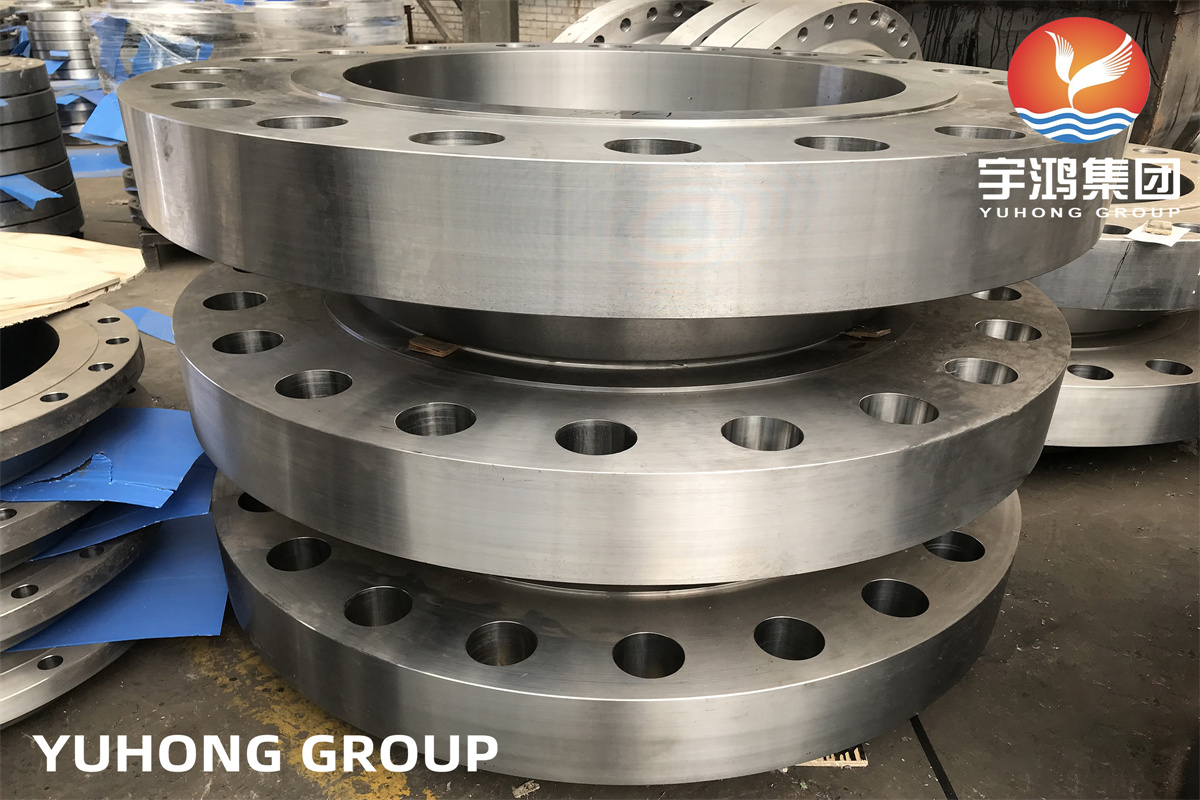

High Strength and Toughness

The high strength and toughness of Inconel make it a reliable choice for marine applications, where the equipment is subjected to challenging mechanical stresses. Regular maintenance helps preserve these mechanical properties, ensuring the flanges can withstand the rigors of marine operations.

How to Maintain Inconel Flanges for Longevity

Routine Inspection

Regular visual inspections are essential for detecting any signs of corrosion, erosion, or mechanical damage. Schedule routine checks to identify potential issues early on, allowing for timely intervention and preventing extensive damage.

Cleaning and Surface Protection

Marine environments expose equipment to salt spray and moisture, leading to the accumulation of deposits on Inconel flanges. Implement a cleaning regimen using appropriate methods and corrosion inhibitors to protect the surface and maintain the alloy's corrosion resistance.

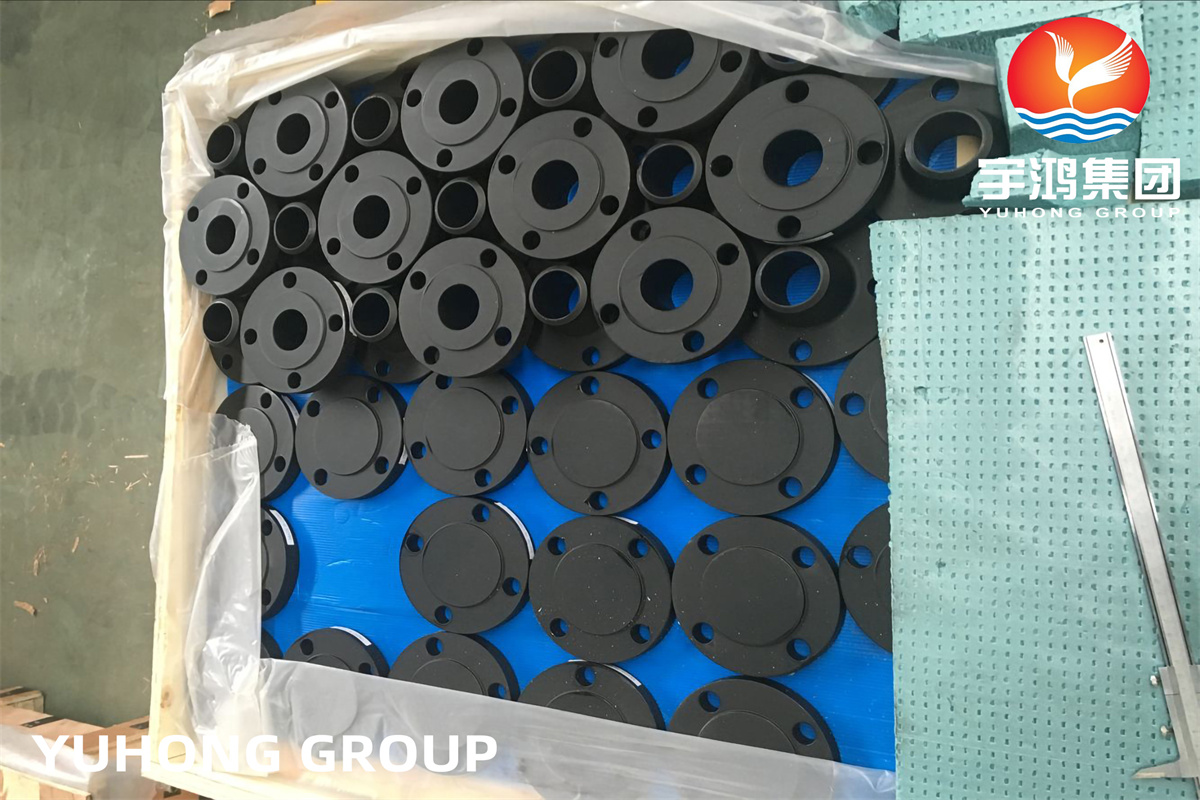

Proactive Corrosion Prevention

Apply anti-corrosion coatings or inhibitors to the Inconel flanges as a proactive measure. These protective layers act as a barrier, shielding the alloy from corrosive elements in the marine environment. Regularly assess the condition of these coatings and reapply them as needed.

Temperature and Stress Management

Monitor the operating temperatures and stresses on Inconel flanges, as excessive heat or mechanical stress can affect their performance. Implement measures to manage and control these factors, ensuring the alloy operates within its designed parameters.

Prompt Repairs and Replacements

Address any identified issues promptly. If corrosion, erosion, or mechanical damage is detected during inspections, undertake necessary repairs or replacements. Timely intervention prevents the escalation of problems, extending the overall lifespan of the Inconel flanges.

Inconel flanges are a valuable asset in marine applications, offering a combination of corrosion resistance and mechanical strength. To ensure their longevity and optimal performance, a proactive approach to maintenance is indispensable. By incorporating routine inspections, effective cleaning practices, corrosion prevention strategies, and prompt repairs, you can uphold the integrity of Inconel flanges in marine environments, contributing to the reliability of your marine systems.

English

English

_副本.webp)