Tubing and piping systems are the lifelines of many industrial processes, transporting fluids and gases safely and efficiently. When it comes to ensuring the reliability and integrity of these systems, adherence to standards is paramount. Among the various standards governing tubing, ASME SA269 holds a crucial place. In this blog, we'll delve into the significance of ASME SA269 in tubing and piping systems, exploring its importance in maintaining safety, quality, and performance.

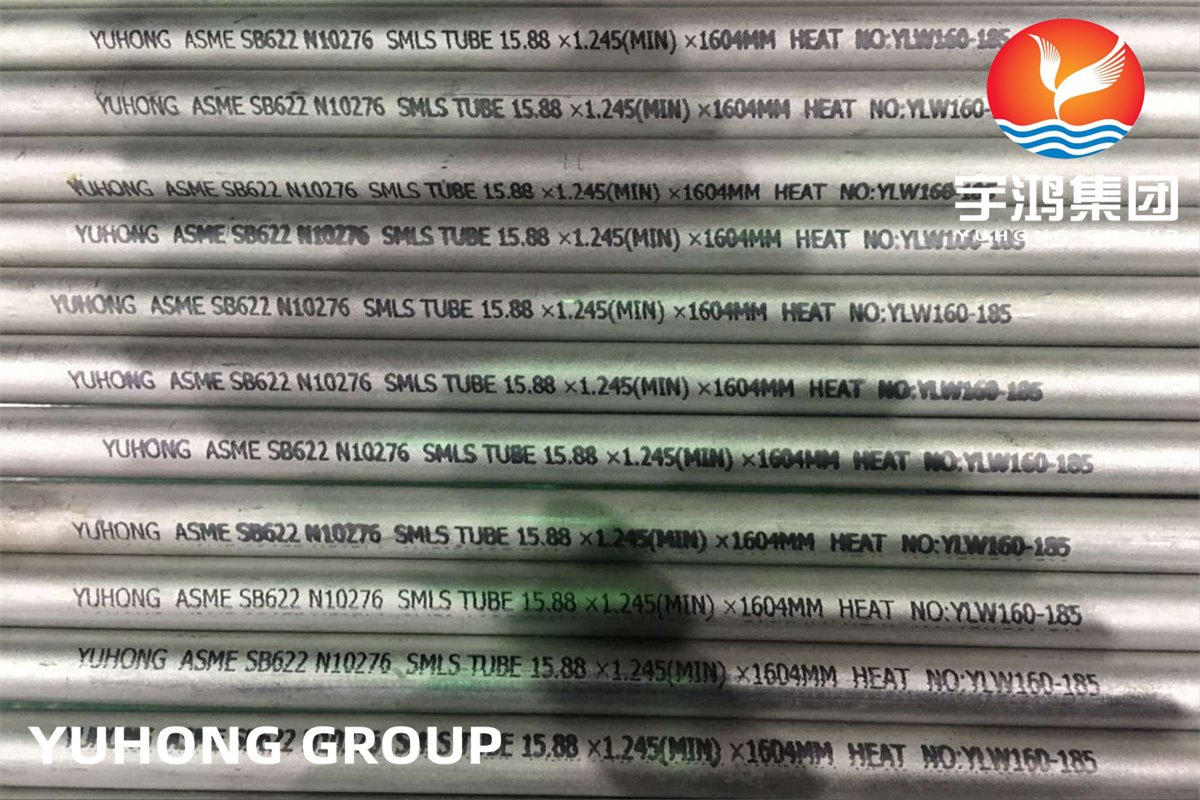

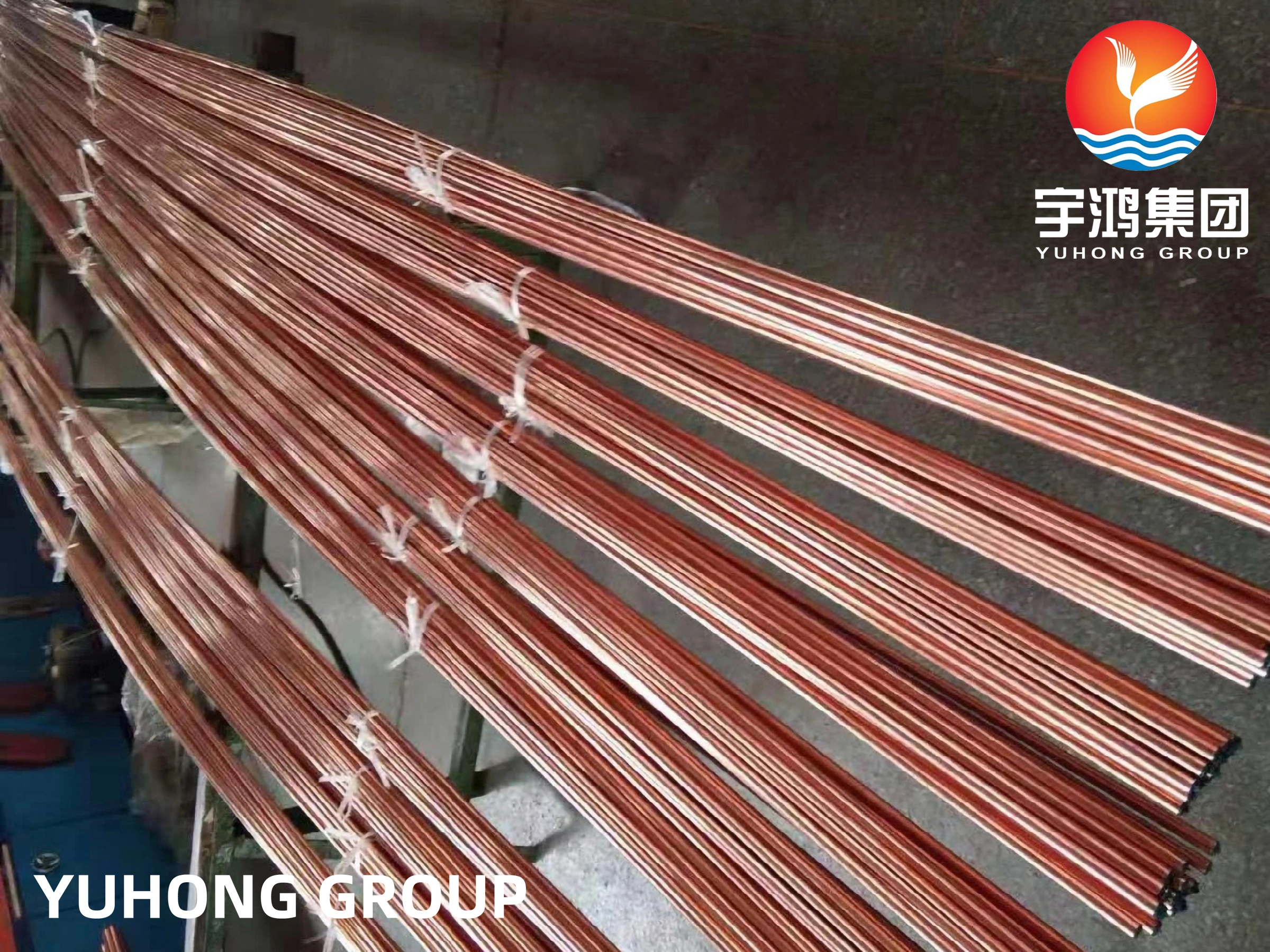

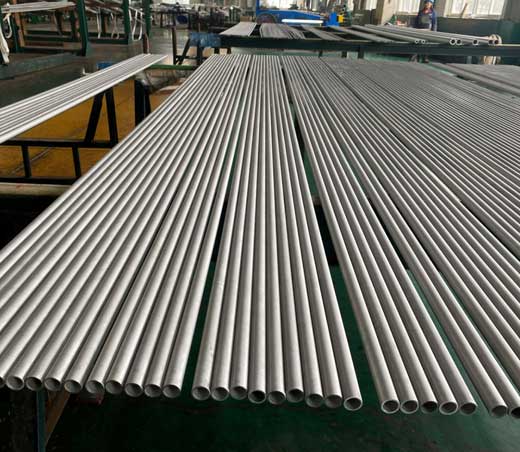

Before we delve into the importance, let's briefly understand what ASME SA269 is. The ASME SA269 specification is a part of the American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code (BPVC). It specifically covers seamless and welded austenitic stainless steel tubing for general corrosion-resisting and low- or high-temperature service. This standard is widely recognized and utilized in industries where the integrity of tubing and piping systems is crucial.

Ensuring Safety and Reliability

Safety is a paramount concern in any industrial setting. Tubing and piping systems must handle various substances, some of which can be hazardous or volatile. ASME SA269 provides guidelines and requirements that help ensure the safe operation of these systems. By specifying materials, manufacturing processes, and quality control measures, it minimizes the risk of failures, leaks, and accidents that could have dire consequences.

Maintaining Quality Standards

Quality is a non-negotiable aspect of tubing and piping systems. ASME SA269 sets stringent quality standards for the materials and manufacturing processes used in the production of stainless steel tubing. This ensures that the tubing is free from defects, has uniform dimensions, and meets the required mechanical properties. Consistency in quality is essential to prevent system failures and costly downtime.

Compatibility and Interchangeability

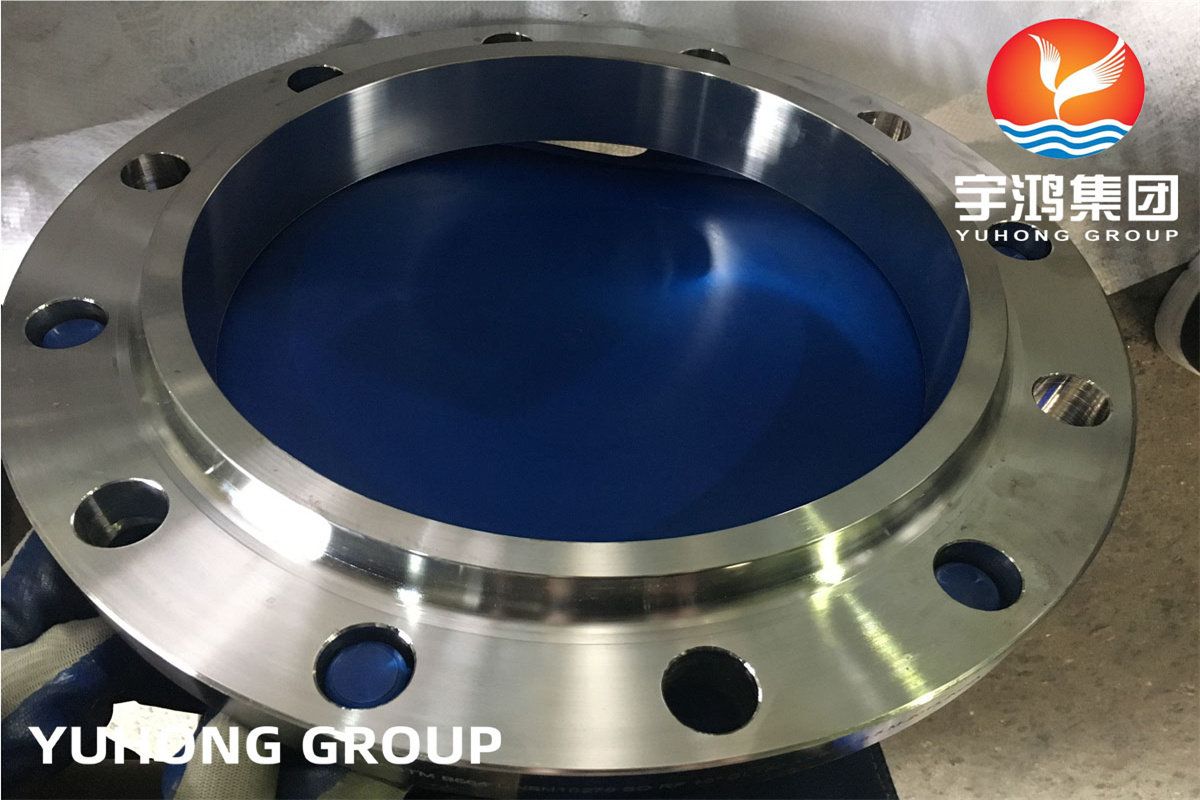

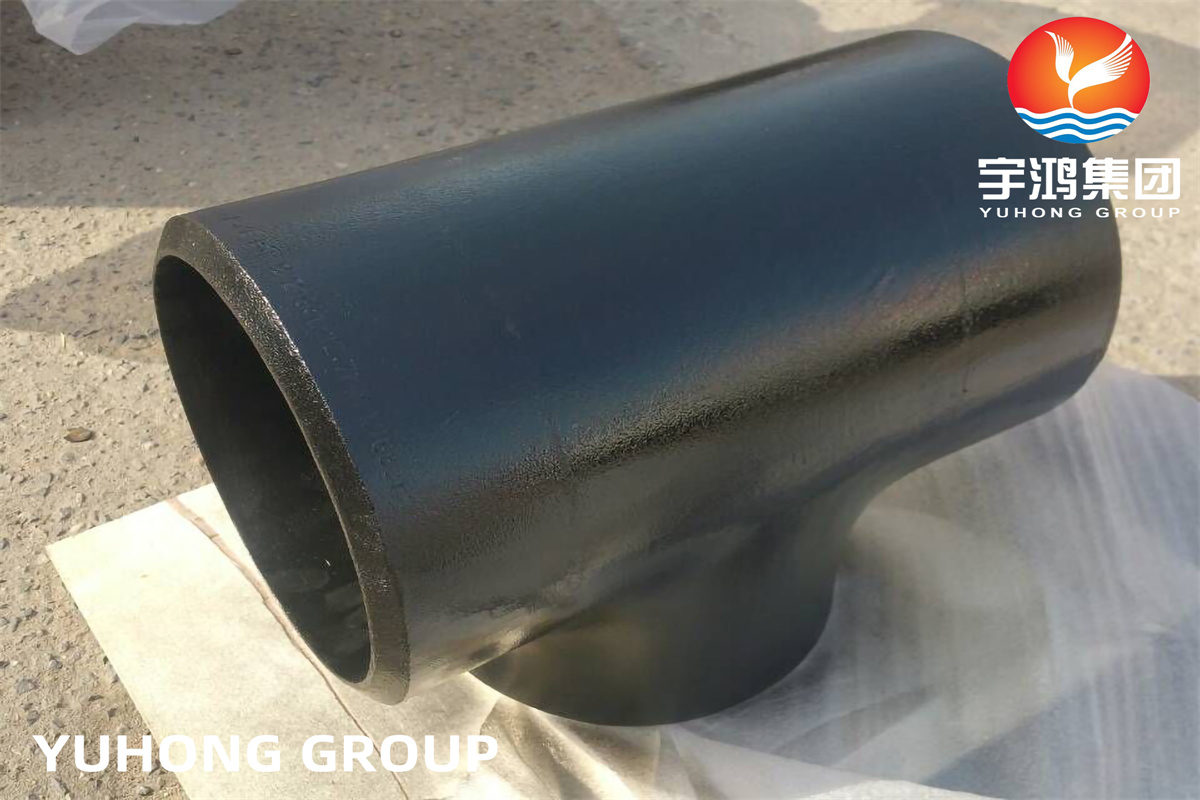

ASME SA269 provides a standardized approach to tubing, ensuring compatibility and interchangeability of components in different systems. This is especially crucial in industries where components from various manufacturers may be used. With ASME SA269-compliant tubing, you can have confidence that components will fit together seamlessly, reducing installation and maintenance challenges.

Performance and Efficiency

Efficiency is a key concern in any industrial process. ASME SA269-compliant tubing is designed to perform optimally in a wide range of conditions. Whether it's conveying fluids at extreme temperatures or withstanding corrosive environments, this tubing is engineered to meet the performance requirements of diverse applications. This performance reliability translates into increased efficiency and reduced downtime.

Regulatory Compliance and Peace of Mind

Adhering to ASME SA269 not only ensures compliance with industry standards but also provides peace of mind. It demonstrates a commitment to safety, quality, and best practices, which can be reassuring for regulatory bodies, customers, and stakeholders. Compliance with recognized standards can also simplify the inspection and certification process.

ASME SA269 plays a pivotal role in maintaining the integrity, safety, and performance of tubing and piping systems across various industries. By adhering to this standard, companies can ensure the quality and reliability of their systems, minimize risks, and uphold the highest safety standards. In an industrial landscape where precision and reliability are paramount, ASME SA269 is an invaluable tool for maintaining the seamless operation of tubing and piping systems.

English

English