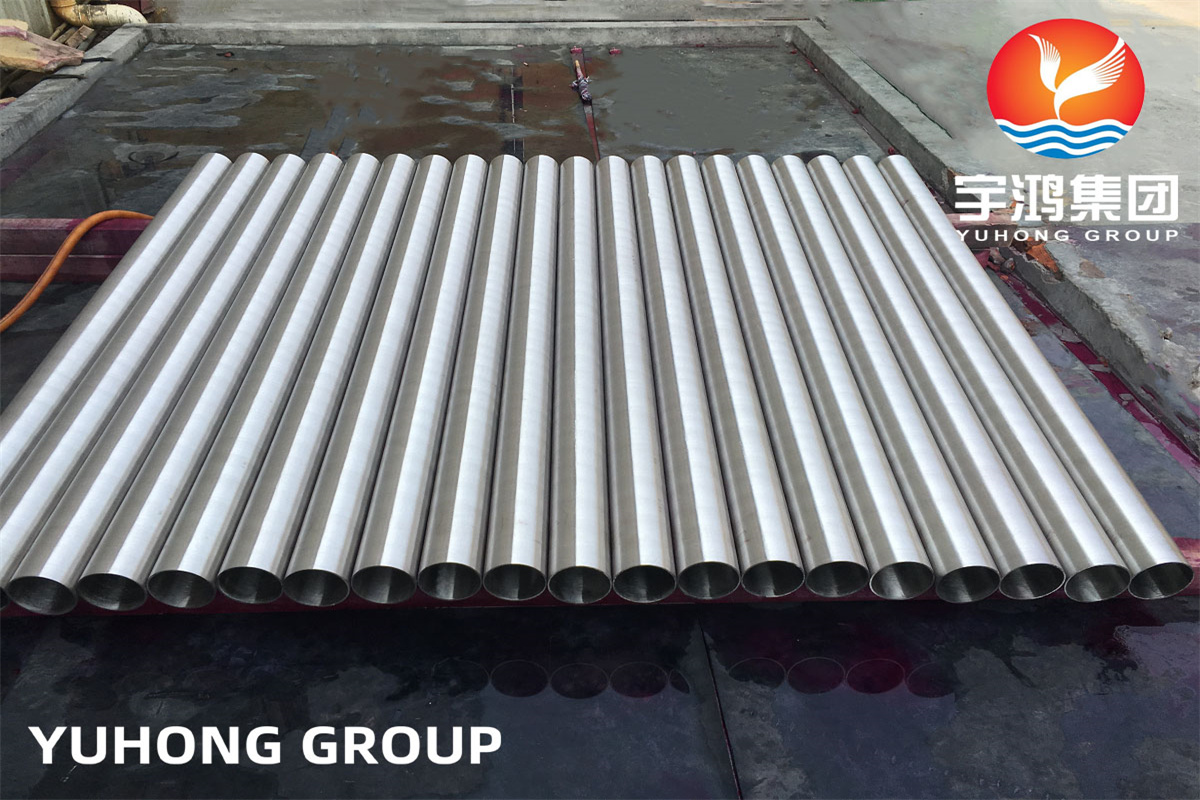

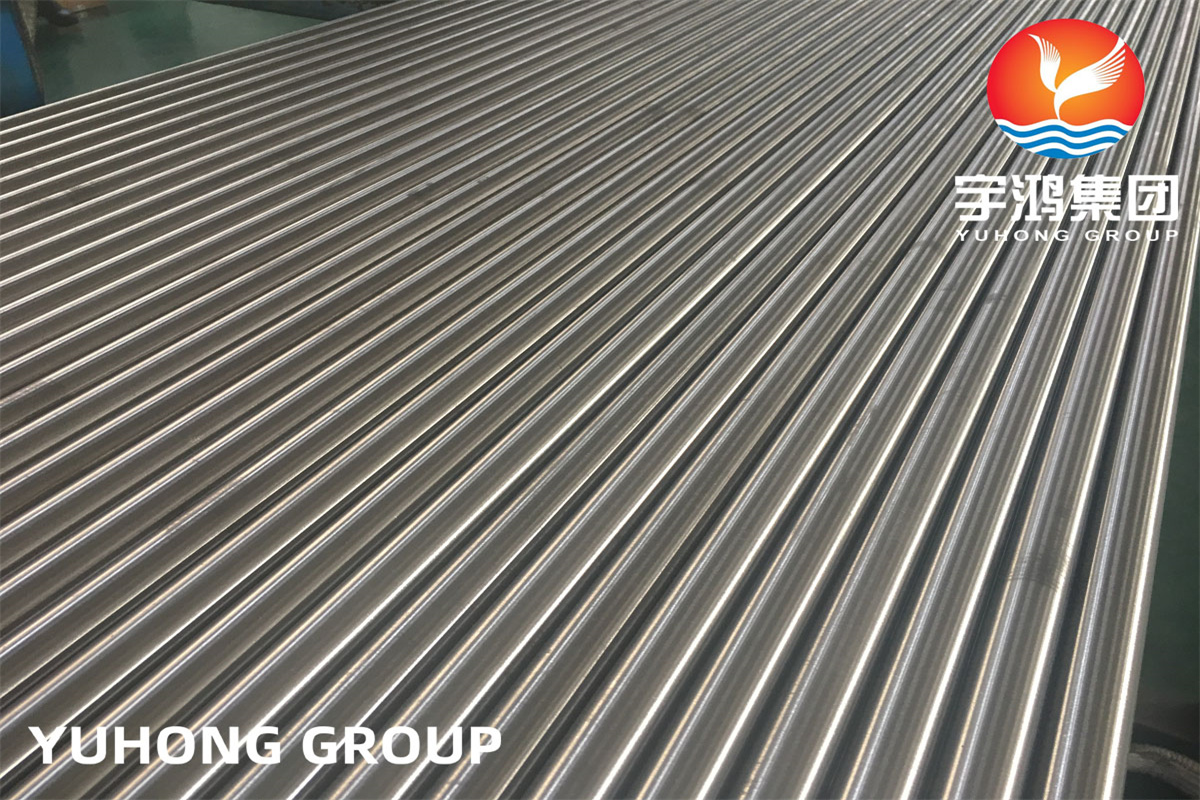

304 stainless steel pipes are not easy to rust, non-magnetic, and not easily corroded. They are suitable for machinery and equipment, precision instruments, and the electrical industry, serving as hardware product fittings. Welded pipes are formed by squeezing steel strips, with relatively uniform wall thickness. However, seamless pipes require perforation and precision rolling during processing, which can easily cause adverse effects on the wall thickness, and the most common problem is the size deviation of the wall thickness, which we commonly refer to as uneven wall thickness. Today, we will explain why 304 stainless steel seamless pipes are more prone to uneven wall thickness compared to welded pipes.

Manifestations of uneven wall thickness in stainless steel seamless pipes

Wall thickness deviation is a common defect in stainless steel pipes. The minimum average wall thickness deviation and its relationship with the pipe-making process are as follows: pipe-making equipment includes perforation machines, rolling mills, and tension reducing machines. Taking thin-walled stainless steel pipe billets as an example: the wall thickness deviation from the perforation machine is at least 7.5%, which decreases to 4.5% after extension rolling; it increases to 7% after expanding the diameter and then decreases to 4.5% after tension reducing.

In general, the uneven wall thickness of stainless steel seamless pipes is mainly manifested as spiral, linear, thick or thin wall thicknesses at the head and tail ends, etc. Eccentric wall thickness for 304 stainless steel pipes will have a series of adverse effects on the strength of the steel pipe and further cold processing, affecting economic benefits. When rolling large-diameter thick-walled stainless steel pipes, the local pressing amount increases, causing cracks and mechanical failures of the mill.

During the perforation process, due to the rotation of the pipe billet during the perforation process, a spiral wall thickness eccentricity is generated in the middle of the pipe after perforation. The wall thickness distribution of the pipe after perforation has multiple fluctuations with different amplitudes and different periods, showing a complicated wall thickness deviation curve. The perforation line of the perforation machine should be adjusted to make the inclination angle of the two roll ridges equal, and the pipe rolling machine should be adjusted according to the parameters of the rolling table.

Reasons for uneven wall thickness in stainless steel seamless pipes

The wall thickness eccentricity of stainless steel pipes is mainly caused by the following factors: the temperature of the billet cross-section, vibration of the head (the center of the head is not consistent with that of the head rod). Uneven wall thickness caused by early opening of the centering roll, improper adjustment of the centering roll, and shaking of the head rod during the stainless steel pipe rolling process is generally spiral in distribution along the entire length of the steel pipe.

Adjust the opening time of the centering roll, and do not open the centering roll too early during the rolling process of 304 stainless steel pipes to prevent the head rod from shaking and causing uneven wall thickness. The opening degree of the centering roll needs to be adjusted appropriately according to the change of the pipe diameter and the size of the pipe jitter needs to be considered.

The wall thickness eccentricity of stainless steel seamless pipes caused by the temperature difference of the billet cross-section is caused by the difference in deformation resistance in the circumferential direction when the temperature of the billet cross-section is uneven, resulting in unbalanced pressure on the left and right sides. According to this calculation method, the wall thickness eccentricity caused by the temperature difference of the billet cross-section is ±1.7%, which is equivalent to a temperature difference of 20℃.

The reason why 304 stainless steel seamless pipes are more prone to uneven wall thickness compared to welded pipes is that during precision rolling and perforation processing, the roll angle, billet cross-section temperature, and vibration of the head cause spiral and linear uneven thickness and thick or thin wall thickness at the head and tail ends. In the production of 304 stainless steel pipes, attention should be paid to adjusting various parameters and controlling the temperature to reduce wall thickness unevenness.

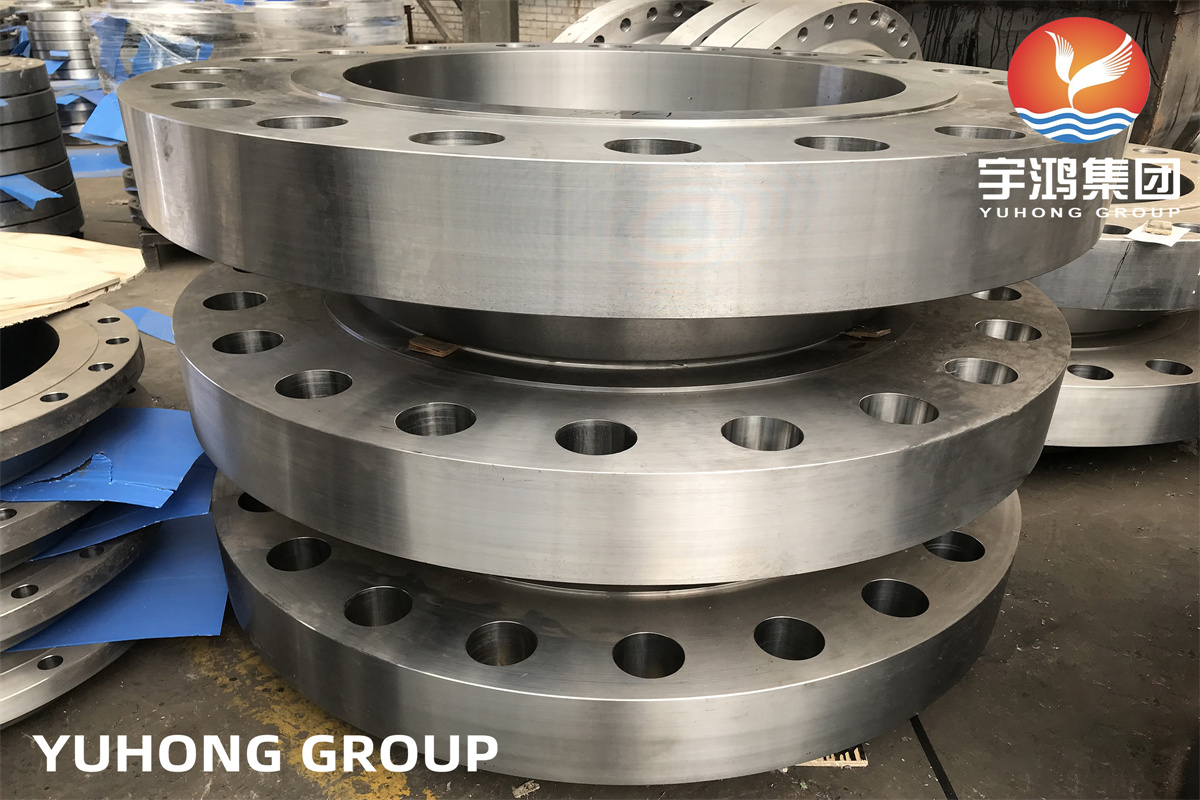

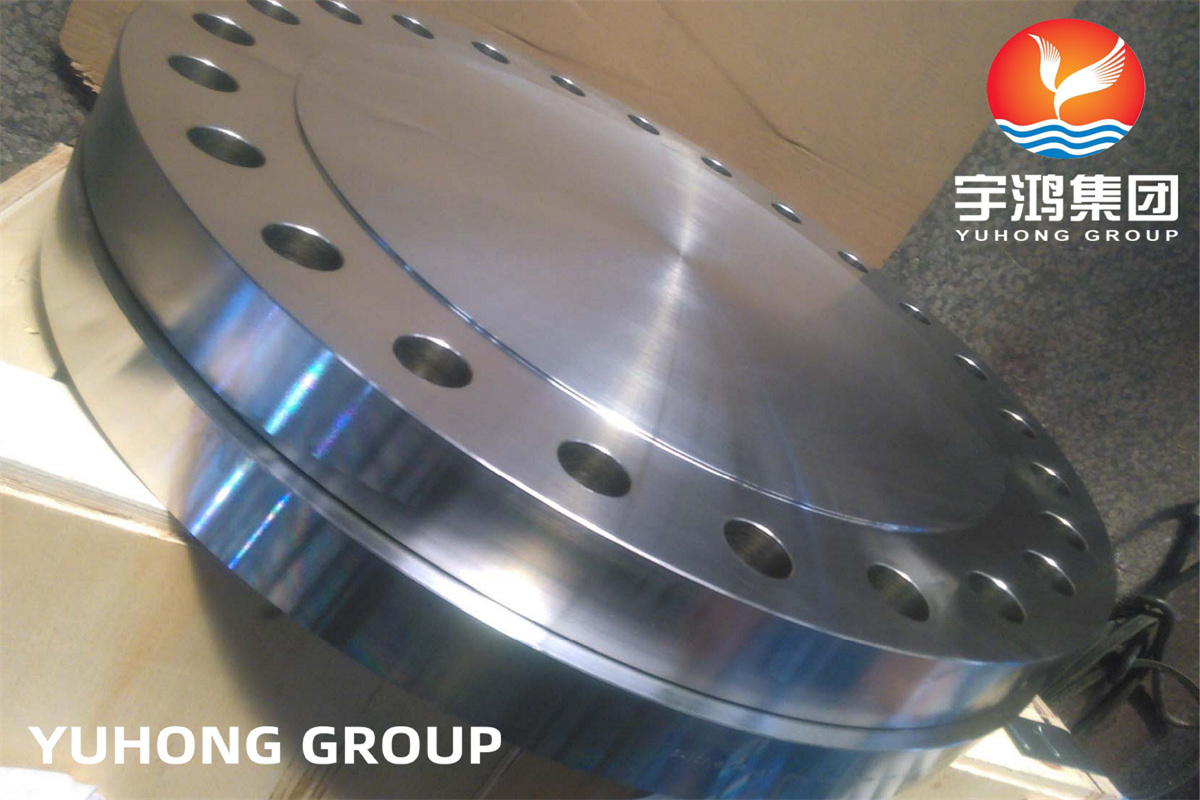

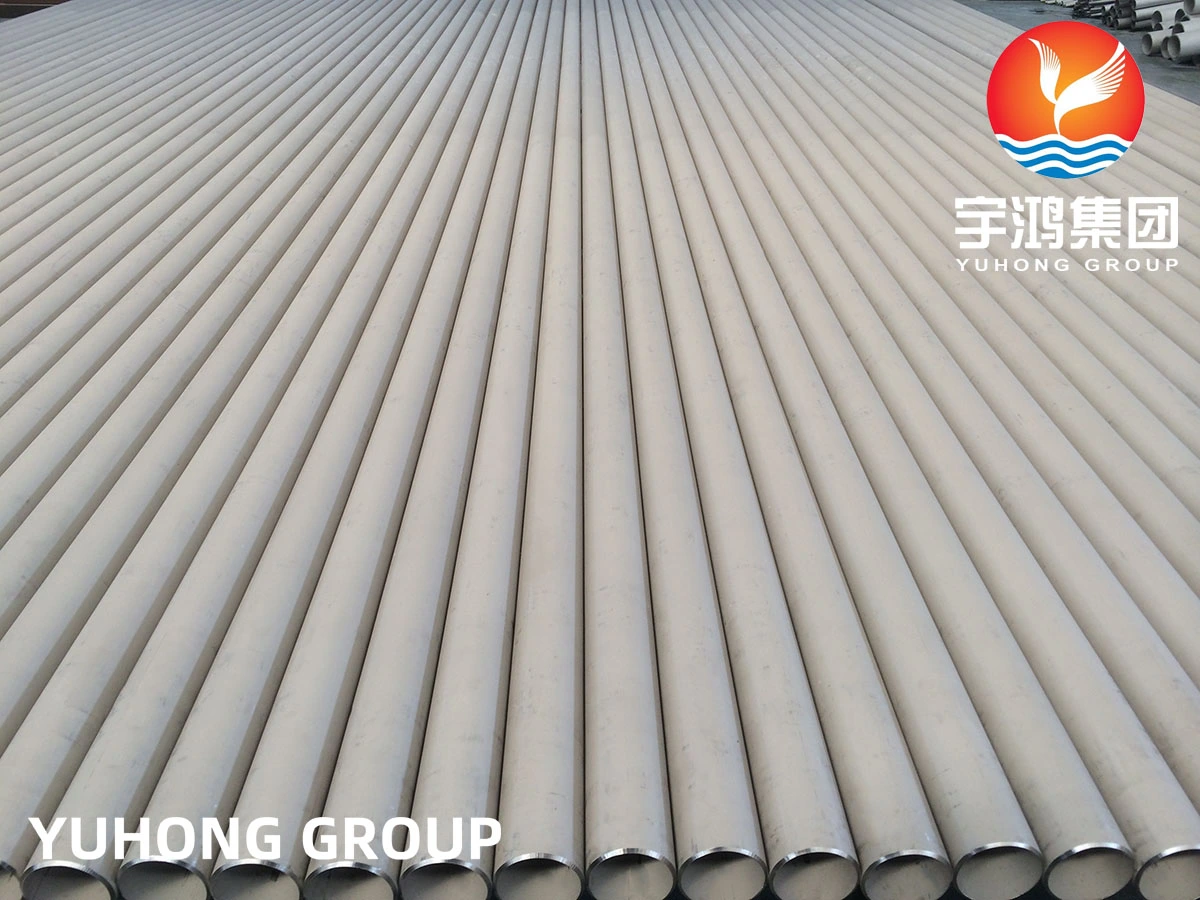

YUHONG has 30 years of development and experience, and is now one of the largest steel manufacturers and exporters in China. We specialize in producing stainless steel, duplex steel, copper-nickel alloy steel, nickel alloy steel pipes, and related accessories and flanges. Our products are widely used in various important fields, such as mining, energy, boilers and heat exchangers, petrochemicals, chemical industry, food factories, paper mills, gas and fluid industries, etc. Feel free to contact us!

English

English

_副本.webp)