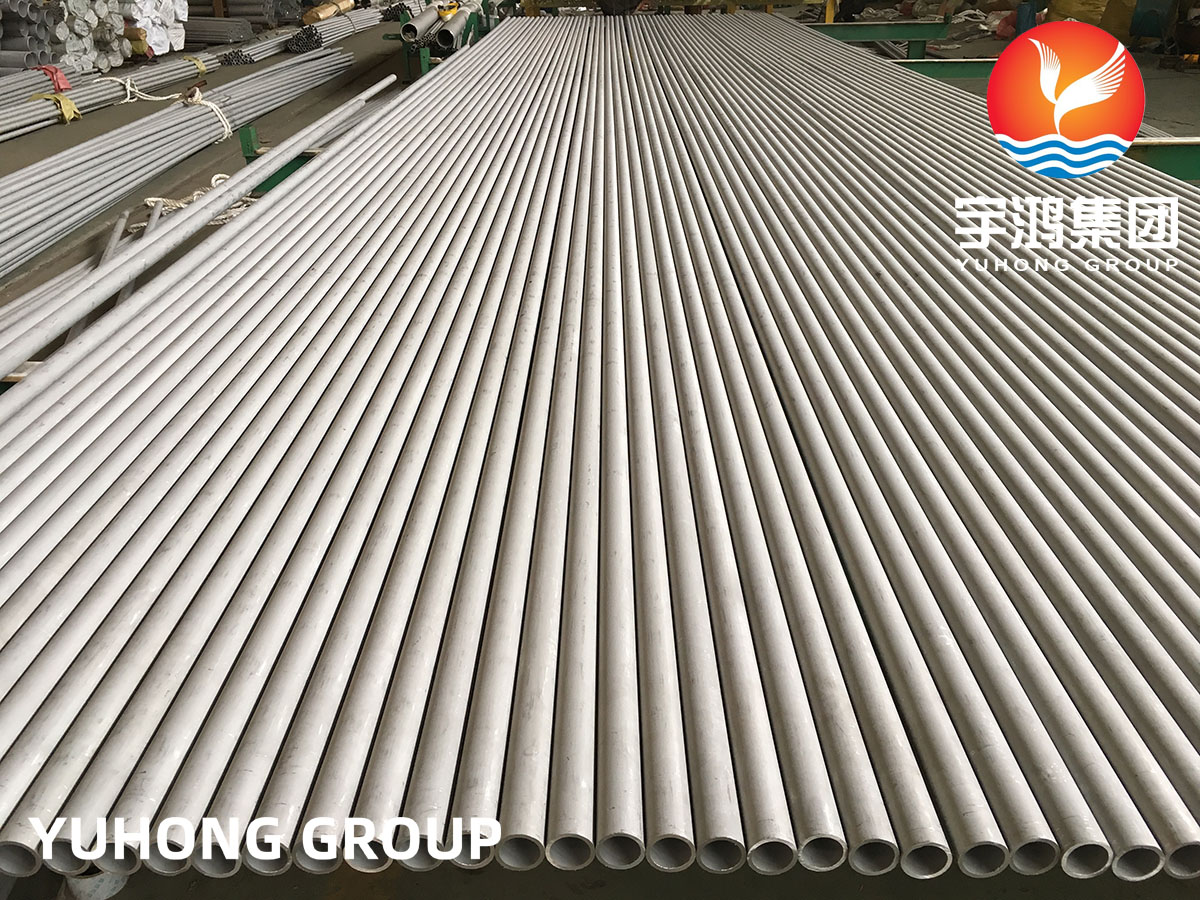

Seamless stainless steel tube is a kind of long steel material with hollow cross section and no seams around. The thicker the wall thickness of the product, the more economical and practical it is, and the thinner the wall thickness, the higher the processing cost will be. The process of this product determines its limited performance. Seamless stainless steel tube can be divided into hot-rolled tube, cold-rolled tube, cold-drawn tube, extruded tube, etc. according to different production methods.

Manufacturing process of stainless steel pipe

Hot-rolled method of seamless stainless steel tube

Hot-rolled seamless stainless steel tube is generally produced on automatic pipe rolling units. The solid tube blank is inspected and surface defects are removed, then cut into the required length, center-aligned on the end face of the perforated end of the tube blank, and then sent to the heating furnace for heating and perforated on the perforation machine. While perforating, it rotates and advances continuously. Under the action of the rolls and the mandrel, the cavity inside the tube blank gradually forms, which is called the rough tube. Then it is sent to the automatic pipe rolling unit for further rolling. Finally, the tube wall is uniformly thickened by the sizing machine, and the specifications are achieved by the sizing machine. Using a continuous pipe rolling unit to produce hot-rolled seamless steel pipes is an advanced method.

Cold-rolled and cold-drawn method of seamless stainless steel tube

In order to obtain smaller sizes and better quality seamless tubes, cold rolling, cold drawing, or a combination of both methods must be used. Cold rolling is usually carried out on a two-roll mill, and the steel tube is rolled in a circular hole type composed of a variable-section circular hole groove and a fixed taper mandrel. Cold drawing is usually performed on a single-chain or double-chain cold drawing machine. You may also be interested in

Extrusion method of seamless stainless steel tube

The extrusion method refers to putting the heated tube blank into a closed extrusion cylinder, and the piercing rod and the extrusion bar move together to extrude the extruded part from the smaller die hole. This method can produce smaller diameter steel pipes.

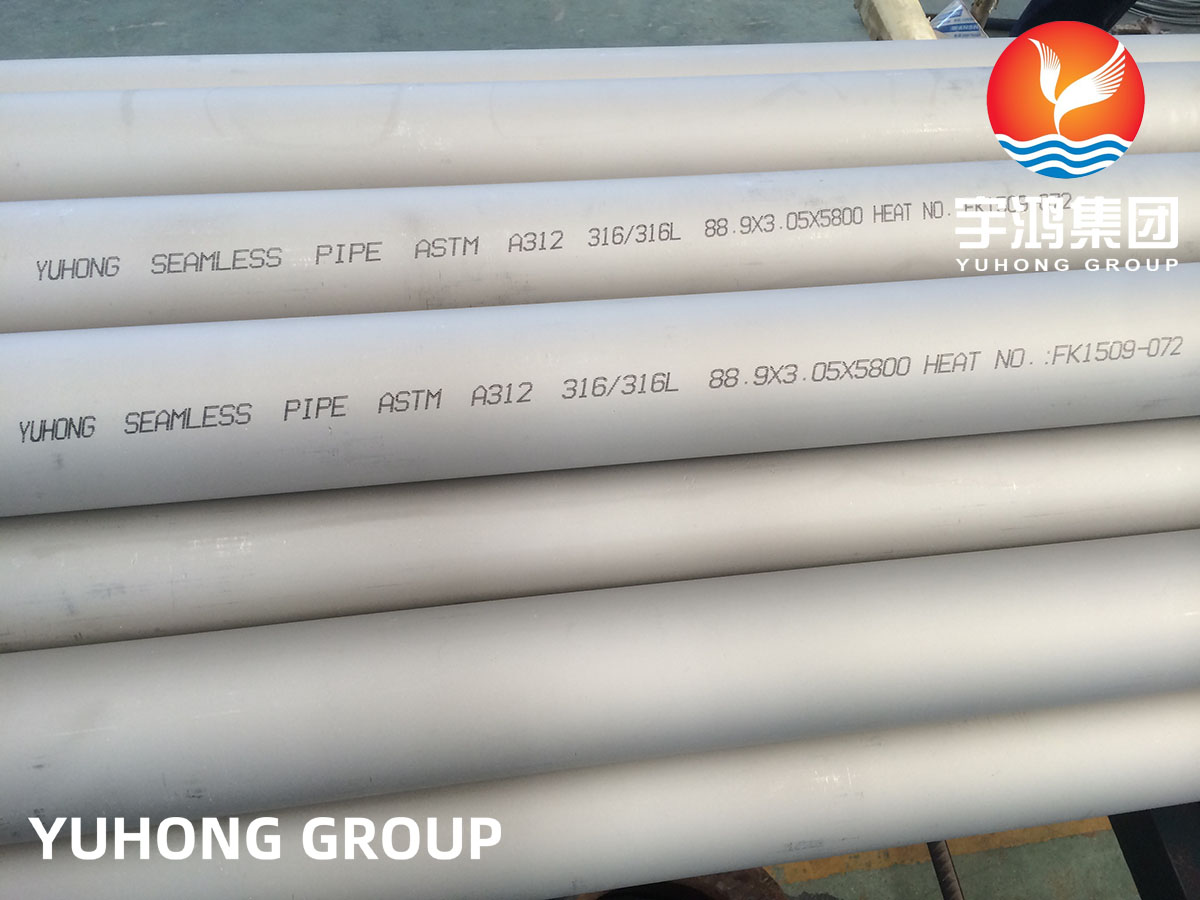

This type of steel pipe can be divided into two categories: seamless stainless steel tube and stainless steel welded tube (seamed tube). According to different manufacturing processes, it can be divided into hot rolling, extrusion, cold drawing, and cold rolling. According to the section shape, it can be divided into round tube and special-shaped tube. The widely used one is the round steel pipe, but there are also some special-shaped stainless steel pipes such as square, rectangular, semicircular, hexagonal, equilateral triangle, and octagonal.

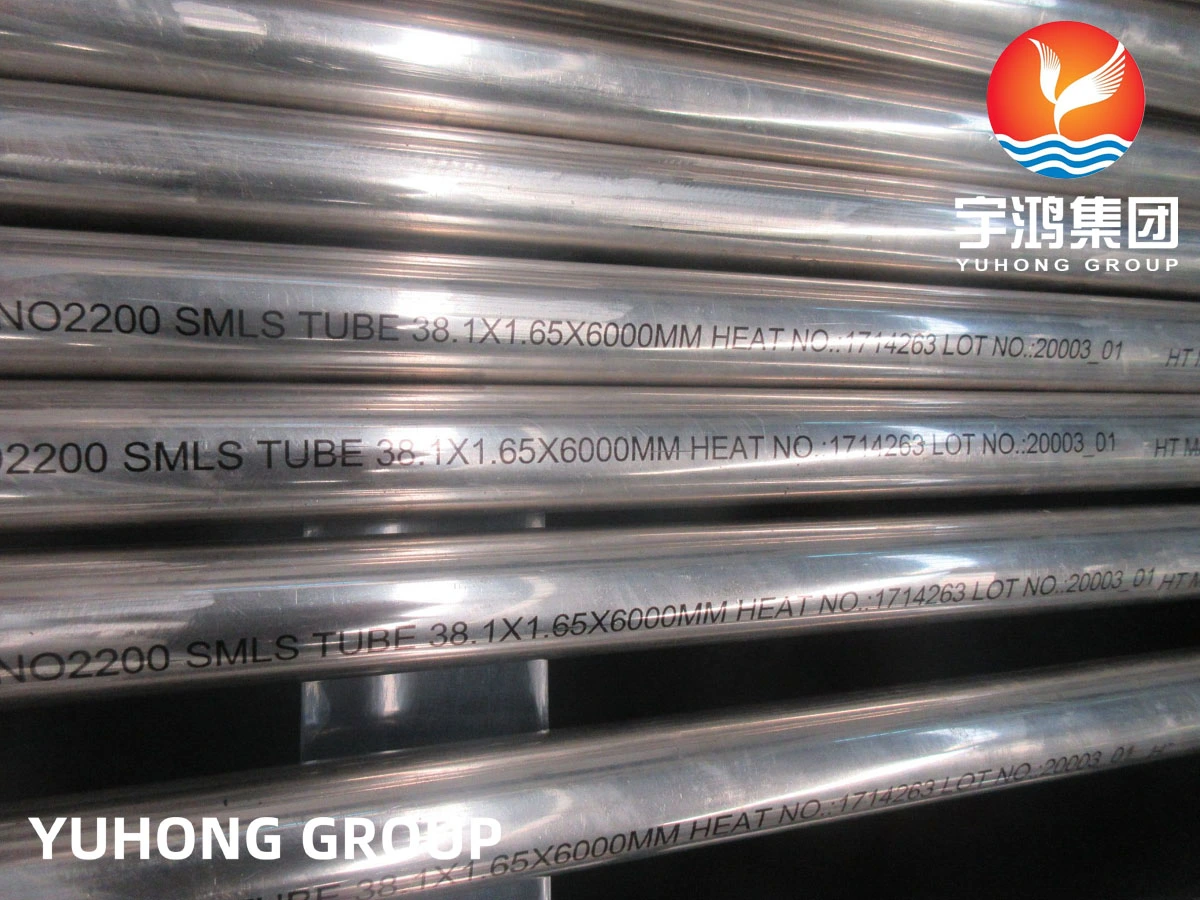

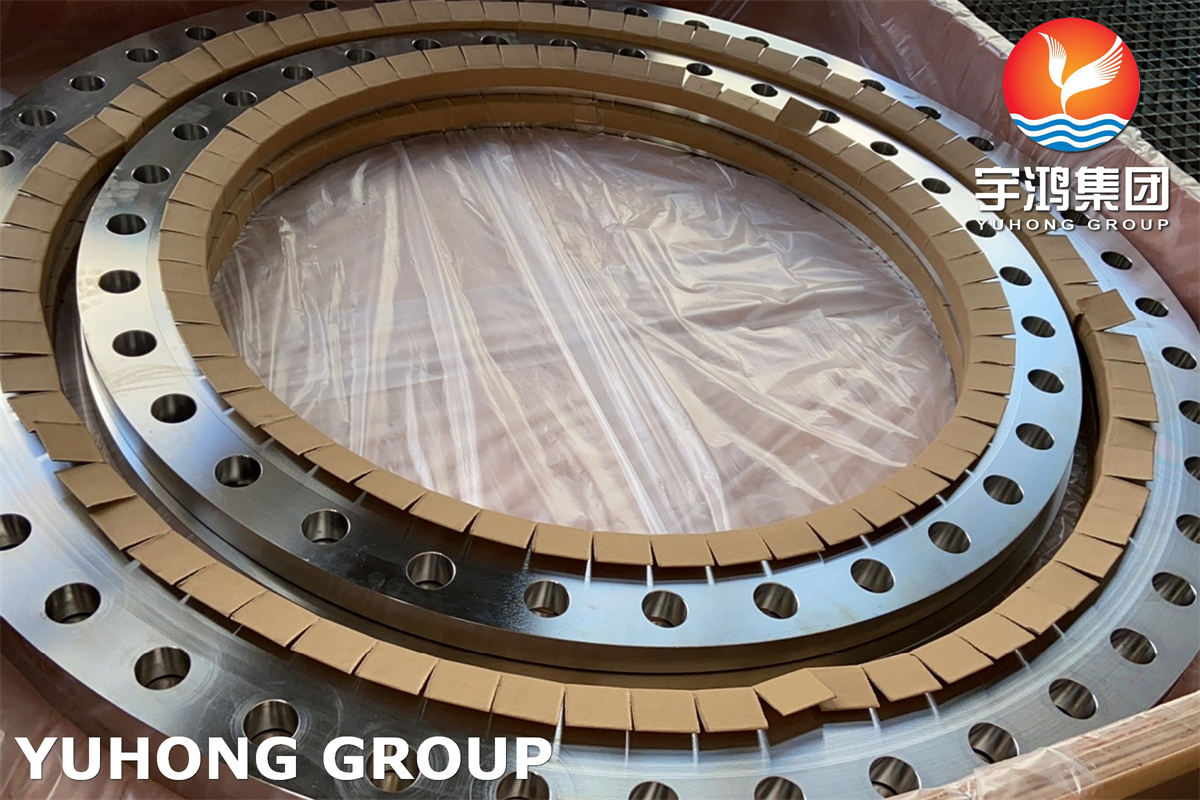

Steel pipes that bear fluid pressure must undergo hydraulic tests to check their pressure resistance and quality. They are qualified if there is no leakage, wetting, or expansion under the specified pressure. Some steel pipes also need to undergo edge curling tests, expanding tests, and flattening tests according to standards or customer requirements. Seamless stainless steel tube, also known as seamless stainless steel tube, is made by piercing the ingot or solid tube blank to make a rough tube, and then made by hot rolling, cold rolling or cold drawing.

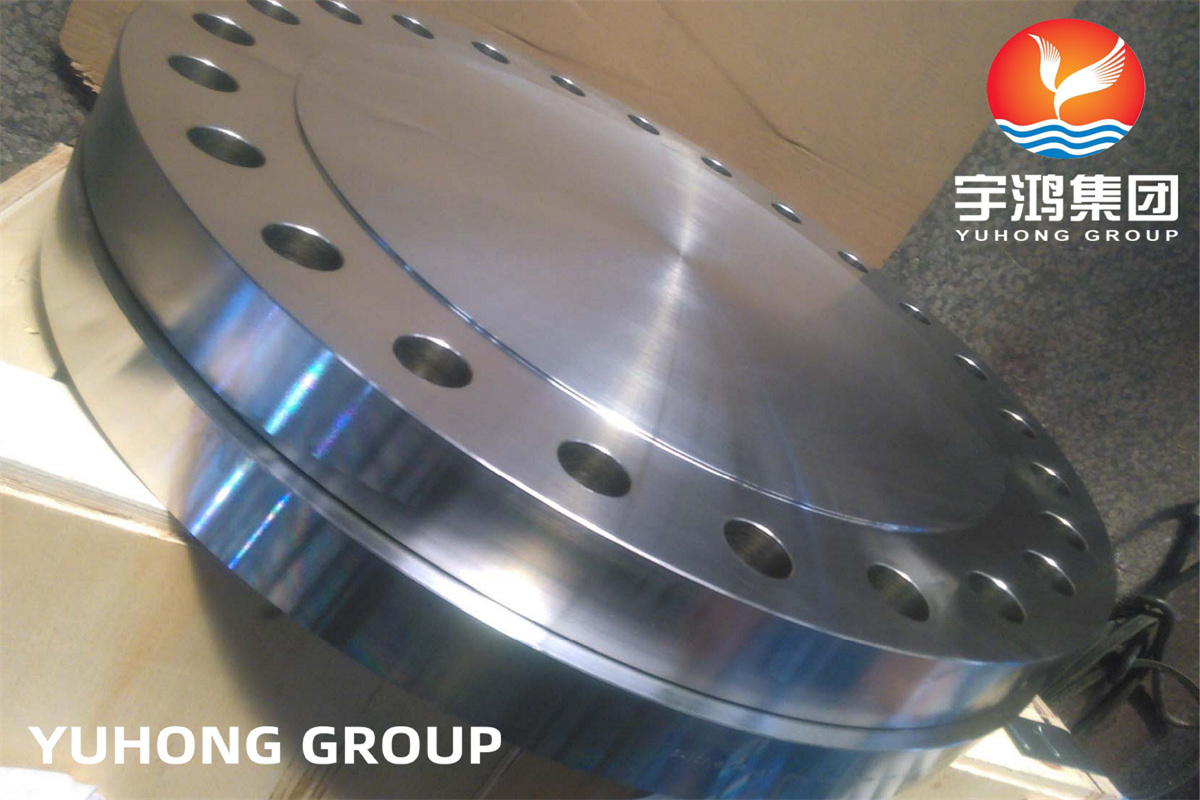

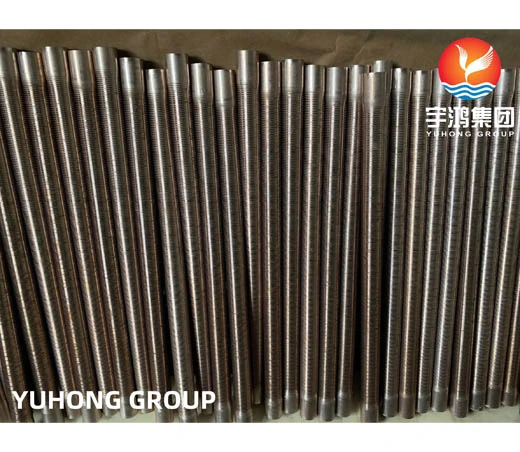

Yuhong Group's prominence as a stainless steel tube manufacturer is underscored by its unwavering commitment to quality, innovation, and customer satisfaction. With a diverse product portfolio including stainless nickel alloy piping products, nickel alloy tubes, and stainless steel finned tubes, Yuhong Group continues to set benchmarks in the industry, providing solutions that empower industries worldwide.

English

English