In the dynamic world of aerospace engineering, where precision and reliability are paramount, the role of materials in aircraft construction cannot be overstated. Copper alloy tubes, often considered the unsung heroes, play a crucial role in enhancing the strength, efficiency, and overall performance of aircraft. This blog takes a deep dive into the significance of copper alloy tubes in aerospace engineering and their profound impact on the performance of modern aircraft.

Aerospace Alloys: The Unyielding Strength of Copper Alloy Tubes

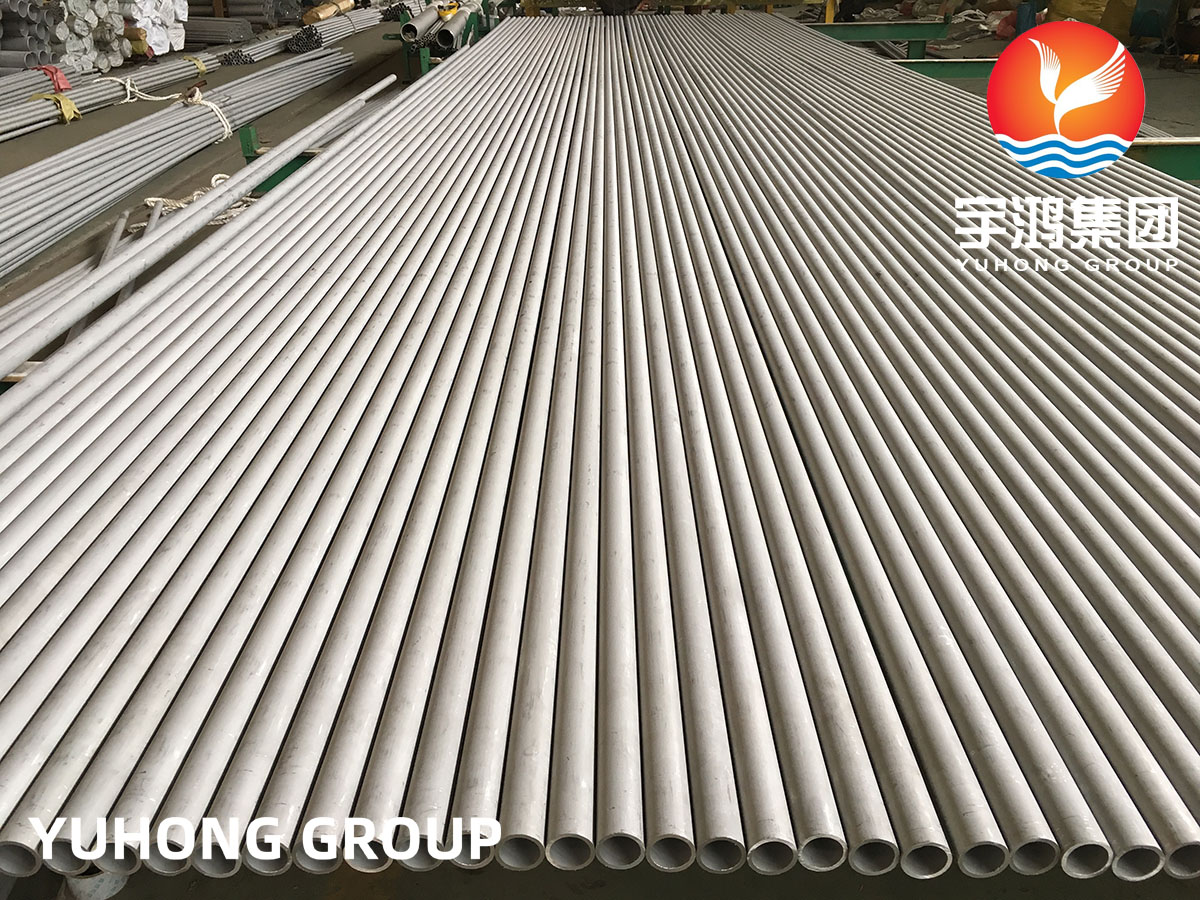

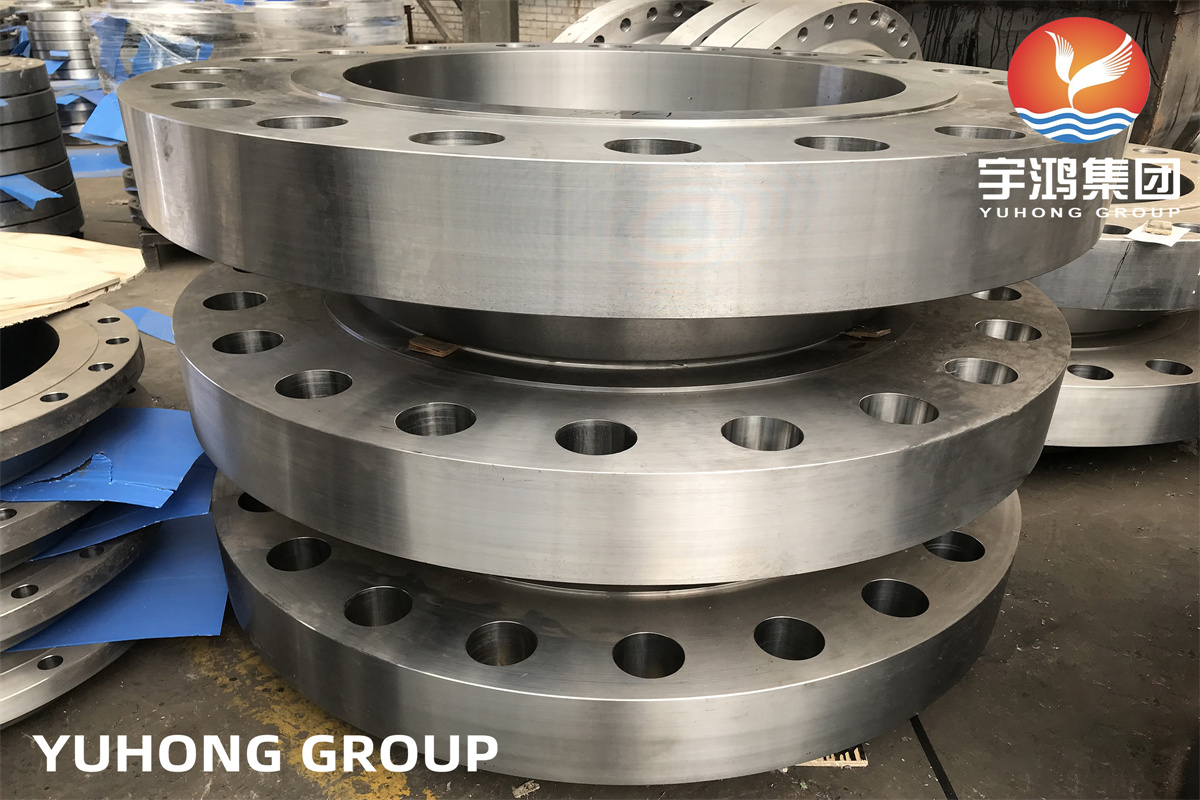

Copper alloy tubes are prized in aerospace engineering for their exceptional strength-to-weight ratio. These tubes, crafted from a blend of copper and other alloying elements, offer a unique combination of durability and lightness. The result is a structural component that enhances the overall strength of the aircraft without compromising its weight limitations, contributing to both safety and fuel efficiency.

Thermal Stability: Copper Alloy Tubes and Aircraft Temperature Control

Maintaining optimal operating temperatures is critical in aerospace applications. Copper alloy tubes excel in their thermal conductivity and stability, making them ideal for managing the heat generated during flight. Whether it's for hydraulic systems, fuel lines, or other critical components, these tubes ensure that temperature fluctuations are controlled, enhancing the longevity and performance of vital aircraft systems.

Corrosion Resistance: Prolonging Aircraft Lifespan

Aircraft are subjected to a range of environmental conditions, including high altitudes and varying temperatures. Copper alloy tubes, renowned for their corrosion resistance, are crucial in ensuring the longevity of aerospace components. Their resistance to corrosion prevents structural degradation, enhancing the lifespan of critical parts and reducing maintenance requirements, which is particularly vital for the rigorous demands of aviation.

Precision Machining: Customization for Aerospace Excellence

The intricate design requirements of aerospace engineering demand precision in every component. Copper alloy tubes, known for their machinability, allow for intricate customization to meet the specific needs of aircraft systems. From fuel lines to hydraulic systems, the ability to tailor copper alloy tubes with precision ensures that they seamlessly integrate into the complex network of components within an aircraft, contributing to overall efficiency.

Lightweight Marvels: Copper Alloy Tubes and Fuel Efficiency

In an era where fuel efficiency is a top priority in aviation, the lightweight nature of copper alloy tubes plays a pivotal role. As aircraft manufacturers strive to reduce weight without compromising structural integrity, the use of copper alloy tubes allows for a more efficient design. This not only contributes to fuel savings but also enhances the overall performance and sustainability of modern aircraft.

Copper alloy tubes stand as silent champions in the field of aerospace engineering, where strength, precision, and efficiency are non-negotiable. Their impact on aircraft performance is felt in the enhanced strength-to-weight ratios, thermal stability, corrosion resistance, precision machining capabilities, and contributions to fuel efficiency. As the aviation industry continues to advance, the strength within copper alloy tubes remains a cornerstone in shaping the future of aerospace engineering, ensuring that aircraft soar to new heights of performance and safety.

English

English