In the realm of heat exchange and thermal efficiency, fin tubes play a pivotal role in various industries. These specialized tubes, equipped with extended surfaces or fins, enhance the heat transfer capabilities of conventional tubing. Let's delve into the applications and advantages of fin tubes, understanding why they are a crucial component in diverse sectors.

Enhanced Heat Transfer in HVAC Systems

Fin tubes find extensive use in Heating, Ventilation, and Air Conditioning (HVAC) systems. The extended surface area provided by the fins facilitates improved heat exchange, making these tubes ideal for applications such as air heaters, air coolers, and other HVAC components. The efficiency of temperature control systems is significantly enhanced through the incorporation of fin tube.

Efficient Cooling in Power Plants

In power generation facilities, efficient cooling is essential for optimal performance. Fin tubes are employed in condensers and air-cooled heat exchangers within power plants. By increasing the surface area available for heat dissipation, fin tubes contribute to the overall efficiency of the cooling process, ultimately enhancing the power generation capacity of these facilities.

Oil and Gas Industry Applications

The oil and gas industry relies on fin tubes for various heat exchange applications. From enhancing the efficiency of heat exchangers in refineries to optimizing the performance of natural gas processing units, finned tubes are integral to maintaining optimal temperatures in critical processes. Their ability to withstand high temperatures and corrosive environments makes them indispensable in these demanding settings.

Process Heating in Manufacturing

Fin tubes play a vital role in process heating within manufacturing industries. Whether in industrial ovens, boilers, or heat exchangers, these tubes contribute to the precision and control of temperature required for various manufacturing processes. The versatility of finned tubes makes them adaptable to a wide range of industrial heating applications.

Aerospace and Automotive Thermal Management

In the aerospace and automotive industries, where weight, space, and efficiency are paramount, fin tubes find applications in thermal management systems. From aircraft heat exchangers to radiators in vehicles, the enhanced heat transfer capabilities of finned tubes contribute to the efficient operation of these transportation systems.

In conclusion, the applications of finned tubes span across diverse industries, playing a critical role in optimizing heat exchange processes. Their ability to enhance thermal efficiency, control temperatures, and withstand harsh environments makes finned tubes a key component in various technological advancements. As industries continue to prioritize energy efficiency and precise temperature control, the demand for finned tube technology is expected to grow, further solidifying its importance in the field of heat exchange and thermal management.

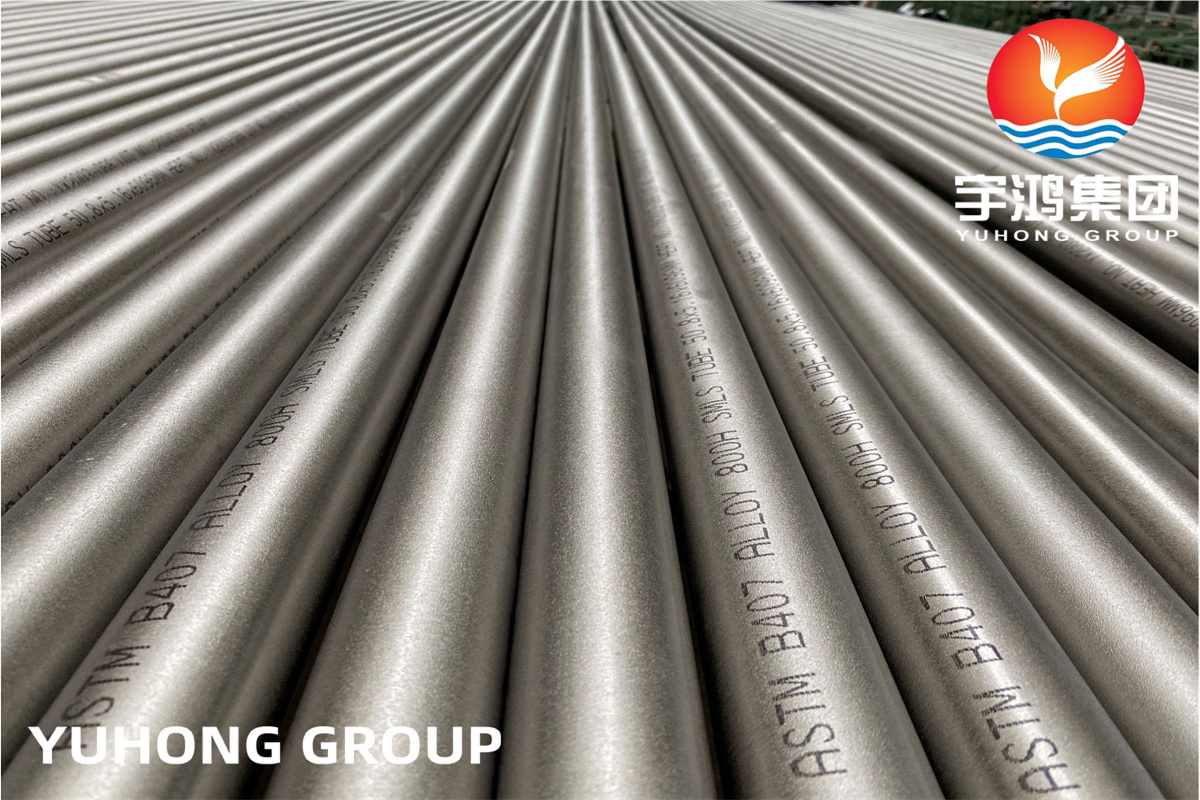

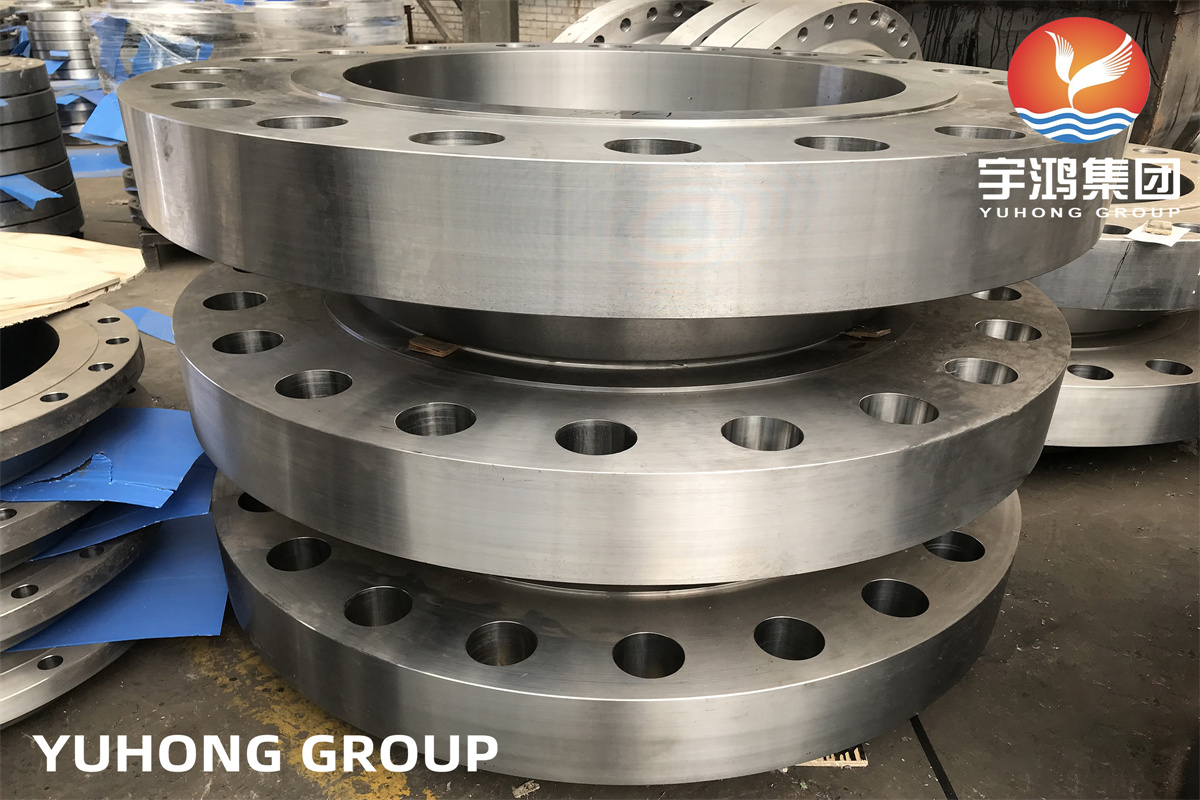

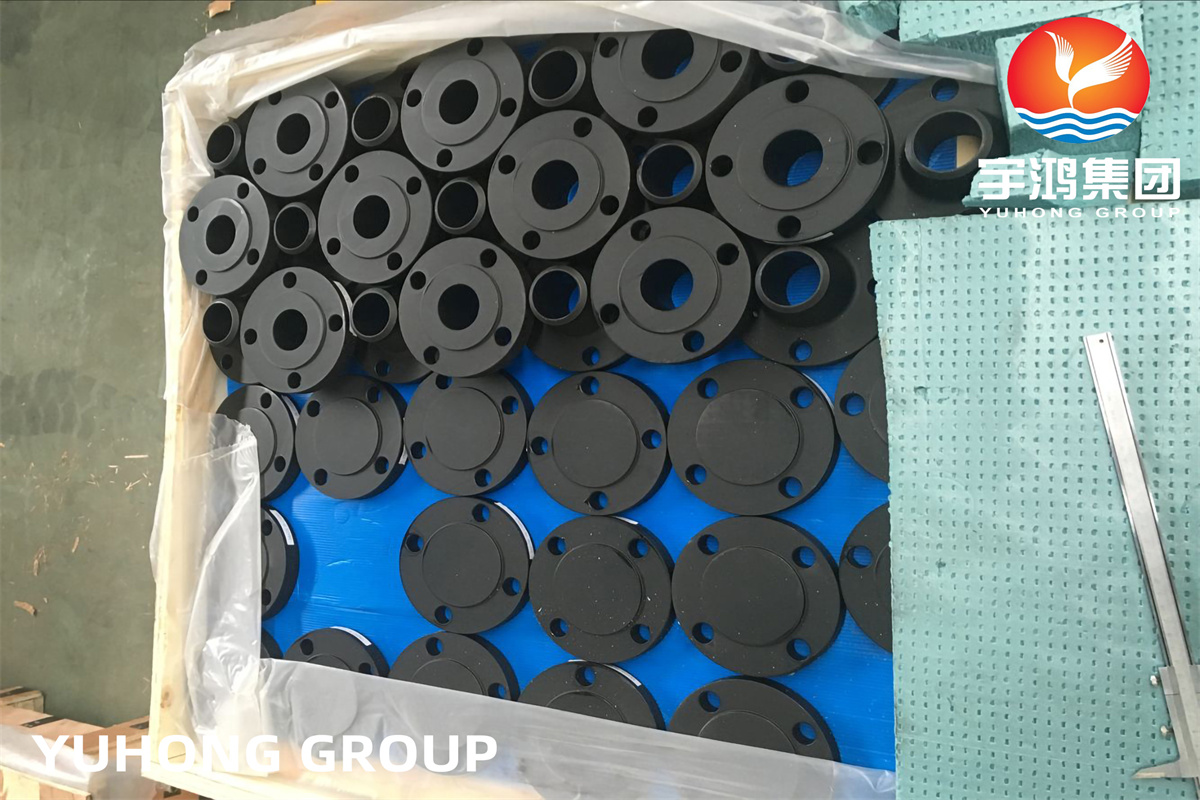

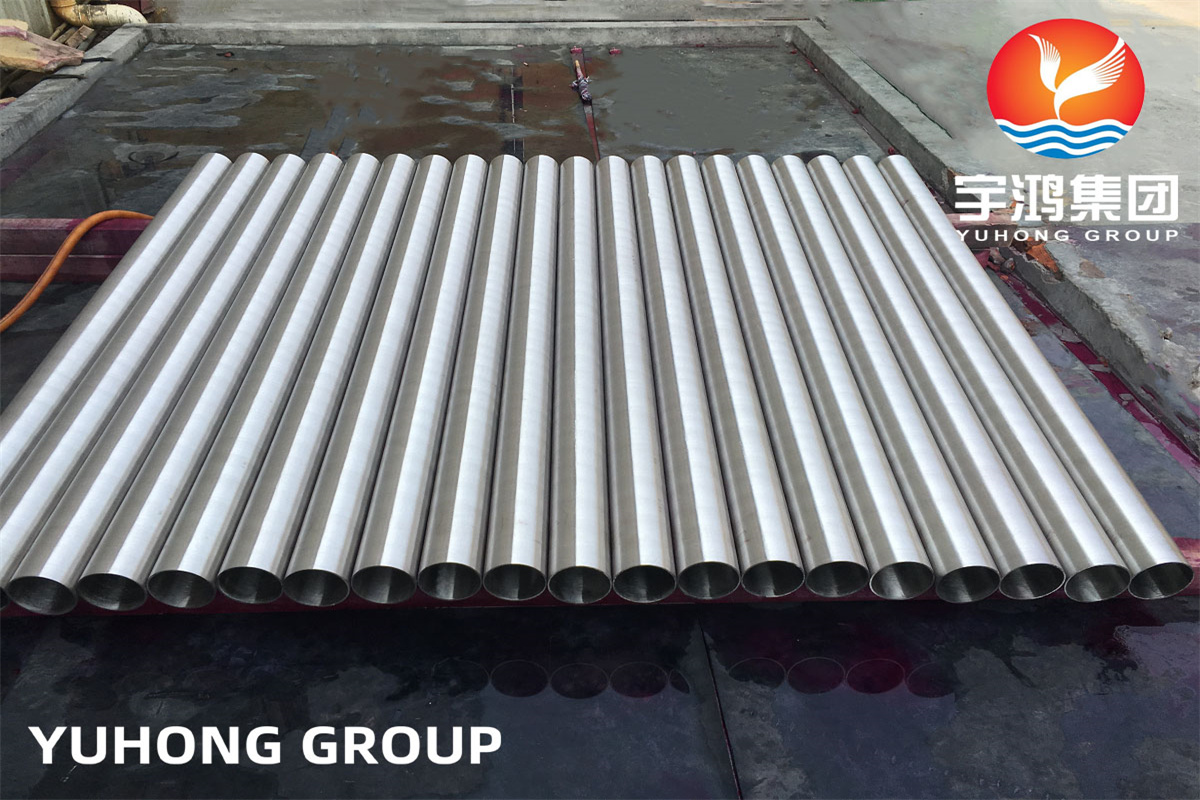

As an experienced and trustworthy fin tube manufacturer, Yuhong Group specializes in providing the following finned tubes:

welding finned tube

extruded finned tube

embedded fin tube

wound finned tube

u fin tube

English

English

_副本.webp)