Stainless steel is a type of steel. Steel refers to steel containing less than 2% of carbon (C), and more than 2% is iron. The addition of chromium (Cr), nickel (Ni), manganese (Mn), silicon (Si), titanium (Ti), molybdenum (Mo), and other alloying elements during the smelting process improves the performance of the steel and makes the steel more resistant to corrosion. (that is, not rusted) is what we often call stainless steel.

What is stainless steel?

What exactly are "steel" and "iron", what are their characteristics, and what is their relationship? How did the 304, 304L, 316, and 316L we usually call come from, and what are the differences between them?

Steel: A material with iron as the main element, carbon content generally below 2%, and other elements.

Iron: A metallic element with atomic number 26. Iron materials have strong ferromagnetism, good plasticity and thermal conductivity.

Stainless steel: resistant to weak corrosive media such as air, steam, and water, or stainless steel. The commonly used steel grades are 304, 304L, 316, 316L, which are 300 series steels of austenitic stainless steel.

Why do stainless steels have different steel grades?

In the smelting process of stainless steel, due to the different varieties of alloying elements added, the amount of addition of different varieties is different. Their characteristics are also different. In order to distinguish them, they are crowned with different steel grades. The following is a table of "alloying elements" content of different steel grades of common decorative stainless steels for reference only:

| Chemical Composition (Mass Fraction, %) Grade | C | Si | Mn | P | S | Cr | Ni |

| 304 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18-20 | 44783 |

| 301 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16-18 | 44720 |

| 202 | ≤0.15 | ≤1.00 | 7.5-10 | ≤0.05 | ≤0.03 | 17-19 | 44657 |

| 201 | ≤0.15 | ≤1.00 | 5.5-7.5 | ≤0.05 | ≤0.03 | 16-18 | 3.5-5.5 |

Performance introduction of stainless steels

304 stainless steel

304 stainless steel is the most common type of steel. As a widely used steel, it has good corrosion resistance, heat resistance, low temperature strength and mechanical properties; good hot workability such as stamping and bending, and no heat treatment hardening (non-magnetic, then use the temperature -196 ℃ ~ 800 ℃).

As a low-carbon 304 steel, its corrosion resistance is similar to that of 304 steel under normal conditions, but after welding or after stress relief, its resistance to grain boundary corrosion is excellent; it can also remain good without heat treatment. High corrosion resistance, operating temperature -196℃~800℃.

316 stainless steel has excellent corrosion resistance, atmospheric corrosion resistance and high temperature strength due to the addition of molybdenum, and can be used under harsh conditions; excellent work hardening (non-magnetic).

As a low carbon series of 316 steel, in addition to having the same characteristics as 316 steel, its resistance to grain boundary corrosion is excellent.

Difference between 304 and 304l

The difference between 304 and 304L stainless steel primarily lies in their carbon content and the impact this has on their performance and usage. Both are types of austenitic stainless steel, widely used due to their corrosion resistance and durability. Here’s a closer look:

Carbon Content:

304 Stainless Steel: It typically contains a maximum of 0.08% carbon.

304L Stainless Steel: The "L" in 304L stands for "Low carbon," and it has a maximum carbon content of 0.03%. This lower carbon content helps minimize/eliminate carbide precipitation during the welding process.

Weldability:

304: Due to its higher carbon content compared to 304L, it might be susceptible to carbide precipitation at the weld joints, which can affect the metal's corrosion resistance in certain environments.

304L: Its lower carbon content reduces the risk of carbide precipitation at the weld joints, making it a better choice for welded structures, especially in corrosive environments.

Corrosion Resistance:

Both grades offer excellent corrosion resistance, but the improved weldability of 304L can make it a better choice for applications requiring welding, as the risk of corrosion at the weld points is minimized.

Mechanical Properties:

Both 304 and 304L stainless steel have similar mechanical properties including strength and hardness. However, the slight difference in carbon content may make 304 slightly stronger than 304L, although the difference is not significant for most applications.

Usage:

304: It’s commonly used in kitchen equipment, architectural paneling, and piping.

304L: Preferred where welding is required, such as in the manufacture of chemical containers, welded pipes, and other applications where the metal's integrity post-welding is crucial.

Cost:

The cost difference between 304 and 304L can vary depending on the supplier and market conditions. Generally, the difference is not significant, but 304L may be slightly more expensive due to its lower carbon content and additional processing needed to reduce the carbon level.

Difference between 316 and 316l

Carbon Content:

316 Stainless Steel: It contains a maximum of 0.08% carbon.

316L Stainless Steel: The "L" stands for "Low carbon," and it has a maximum carbon content of 0.03%. This lower carbon content is designed to reduce carbide precipitation during welding processes.

Weldability:

316: Its higher carbon content can lead to carbide precipitation during the welding process, potentially affecting the material's corrosion resistance in certain environments.

316L: The reduced carbon content minimizes the risk of carbide precipitation during welding, making it preferable for welded structures, particularly in corrosive environments.

Corrosion Resistance:

Both 316 and 316L offer excellent corrosion resistance, especially against chlorides and marine environments. However, 316L, with its lower carbon content, might have a slight edge in preventing corrosion at weld points.

Mechanical Properties:

The mechanical properties of 316 and 316L stainless steel are very similar. The difference in carbon content does not significantly affect their strength, hardness, or durability in a way that would be noticeable in most practical applications.

Usage:

316: Widely used in environments with high levels of chlorides and acids. It's found in marine environments, chemical processing equipment, and in the pharmaceutical and food processing sectors.

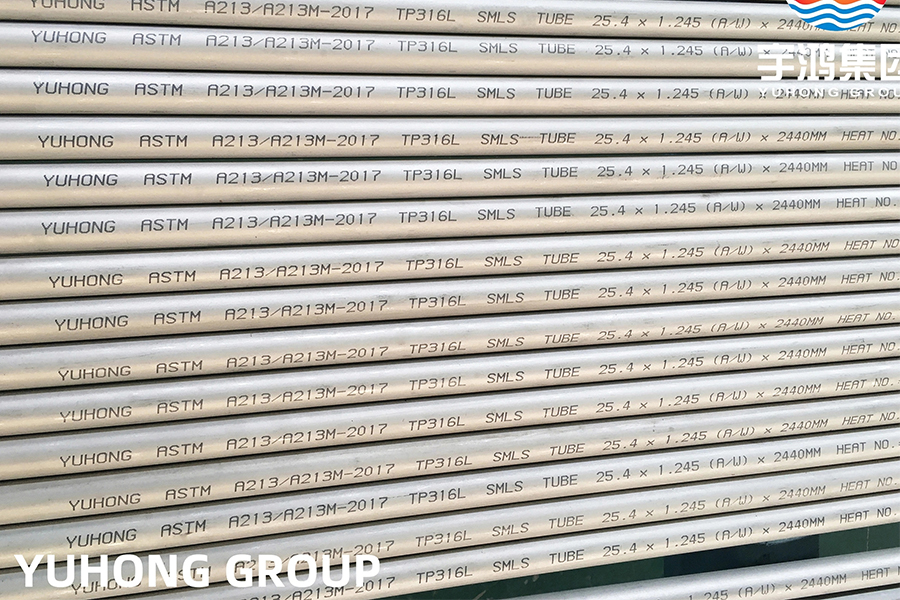

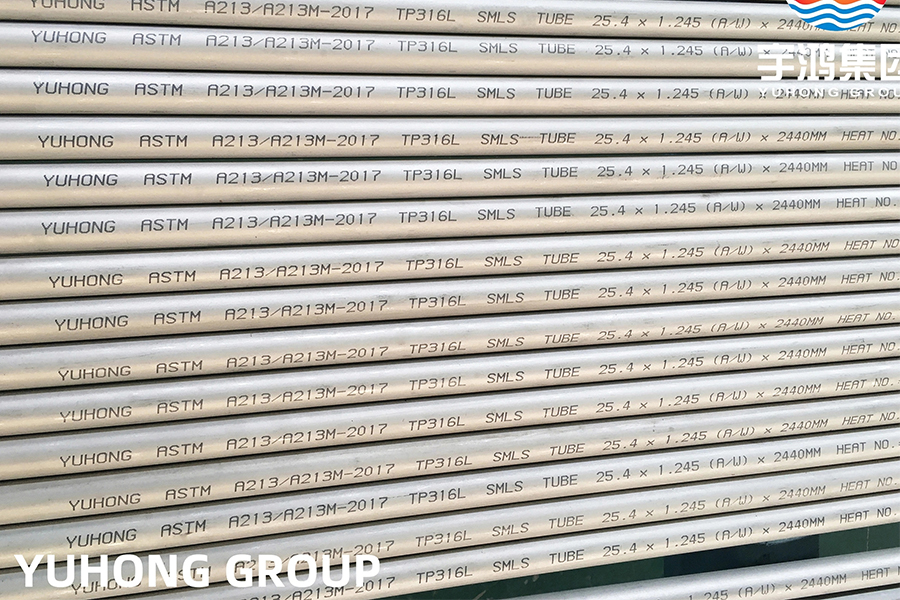

316L: Preferred for its superior weldability. It's used in heavy gauge welded components, such as in chemical containers, industrial piping systems, and in applications where the metal is exposed to corrosive elements for extended periods.

Cost:

The cost difference between 316 and 316L can vary based on the market and the specific form of the material (e.g., plate, sheet, bar). Generally, 316L may be slightly more expensive due to its lower carbon content and the additional processing it requires.

English

English

(1)_副本_副本.webp)