Duplex stainless steel pipe has good welding properties, compared with ferritic stainless steel and austenitic stainless steel, it is neither like ferritic stainless steel welding heat-affected zone, due to severe coarsening of the grain and plastic toughness significantly reduced, nor like austenitic stainless steel, the welding heat cracking is more sensitive.

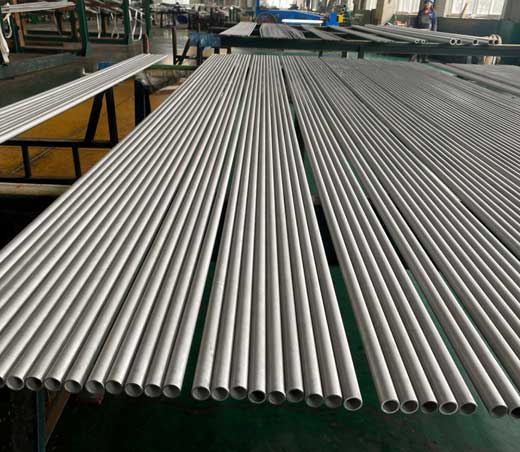

The application of duplex stainless steel pipe

Due to its special advantages, duplex stainless steel pipe provided by duplex stainless steel pipe suppliers is widely used in petrochemical equipment, seawater and wastewater treatment equipment, oil and gas pipelines, paper machinery, and other industrial fields. In recent years, it has also been studied for the bridge load-bearing structure field, with good prospects for development. Duplex stainless steel is in its solid hardening organization in the ferrite phase and austenite phase each half, the general minimum phase content also needs to reach 30%.

Duplex stainless steel tube safety requirements

1, the need to control the phase ratio, the most appropriate ratio is about half of the ferrite phase and austenite phase, where the number of a phase can not exceed 65% at most, so as to ensure that there is the best overall performance. If the proportion of the two phases is out of balance, for example, the number of ferrite phase is too much, it is easy to form single-phase ferrite in welding, in some media sensitive to stress corrosion rupture.

2, need to master the duplex stainless steel tube tissue transformation law, familiar with the TTT and CCT transformation curve of each steel grade, which is the correct guidance for the development of duplex stainless steel heat treatment, hot forming and other processes, duplex stainless steel brittle phase precipitation is much more sensitive than austenitic stainless steel.

3, The working temperature range of the duplex steel tube is from -50 to 250 ℃, the lower limit depends on the steel brittle transformation temperature, the upper limit by 475 ℃ brittle limit, the upper temperature can not exceed 300 ℃.

4, duplex stainless steel tube after solid solution treatment requires fast cooling, slow cooling will cause the precipitation of brittle phase, which leads to the toughness of the steel, especially the decline in local corrosion resistance.

5, high chromium-molybdenum duplex stainless steel tube hot processing and hot forming the lower limit temperature can not be lower than 950 ℃, super duplex stainless steel can not be lower than 980 ℃ low chromium-molybdenum duplex stainless steel can not be lower than 900 ℃, to avoid the precipitation of brittle phase in the processing process caused by surface cracks.

6, can not use austenitic stainless steel commonly used 650-800 ℃ stress relief treatment, generally using solution annealing treatment. For the surface of low-alloy steel after overlay duplex stainless steel, the need for 600-650 ℃ overall stress relief heat treatment, must be considered due to the precipitation of brittle phase brought about by the toughness and corrosion resistance, especially the problem of local corrosion resistance decline, as far as possible to shorten the heating time in this temperature range. Low alloy steel and duplex stainless steel composite plate heat treatment issues should also be considered at the same time.

7, need to be familiar with the understanding of duplex stainless steel pipe welding laws, can not all apply austenitic stainless steel welding, duplex stainless steel equipment can be safely used with the correct grasp of the steel welding process has a great relationship, some equipment failure is often related to welding. The key lies in the control of line energy and interlayer temperature, the correct choice of welding materials is also important. The ratio of the two phases of the welded joint (weld metal and weld HAZ), especially the weld HAZ to maintain the necessary amount of austenite, which is important to ensure that the welded joint has the same performance as the parent material.

8, in different corrosive environments when choosing super duplex tubing, pay attention to the steel corrosion resistance is always relative, although the duplex stainless steel tube has better resistance to local corrosion performance, in terms of a duplex stainless steel, he also has a range of applicable media conditions, including temperature, pressure, media concentration, pH, etc., need to be carefully selected. Many of the data obtained from literature and manuals are laboratory corrosion test results, often with the actual conditions of the project there is a gap, so in the selection of materials need to pay attention to, if necessary, the need to carry out in the actual media corrosion test or field conditions under the hanging test, or even simulate the device test.

You may also be interested in:

Stainless steel coil tubing

Nickel alloy tubes

Nickel piping products

English

English