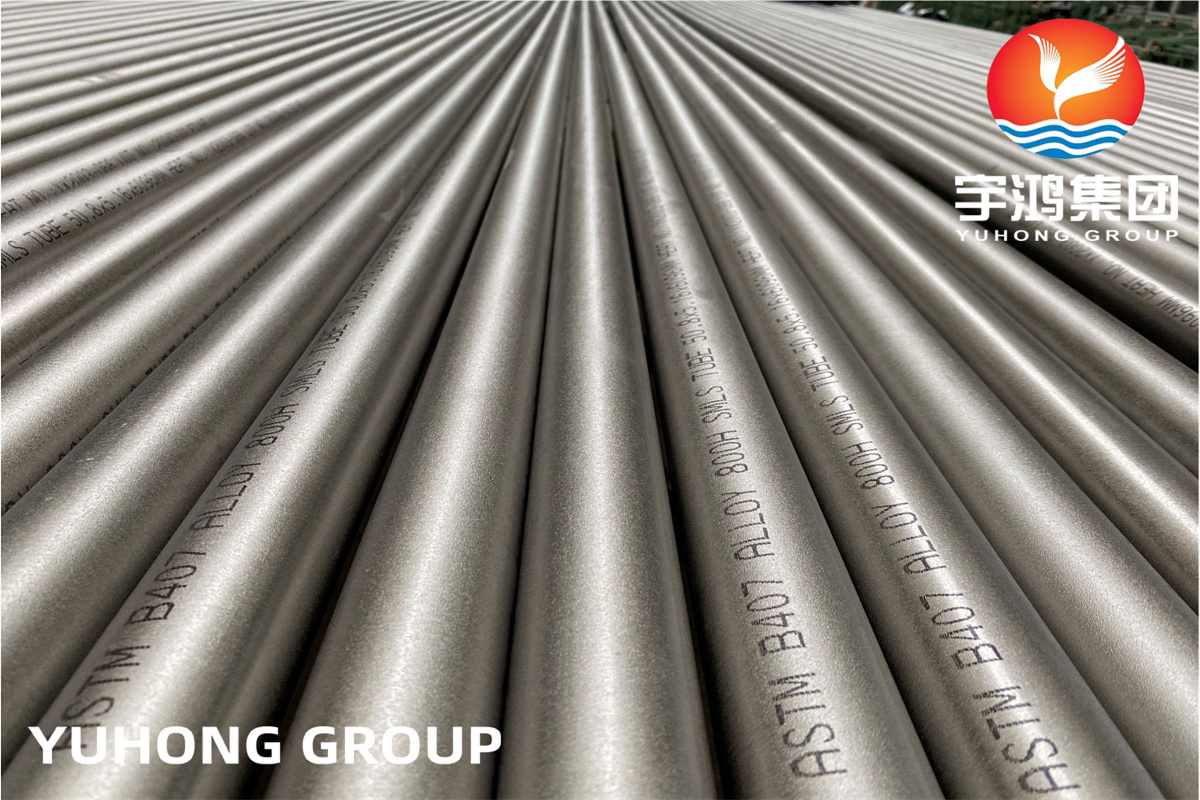

The concept of finned tube

The Finned tube is a Heat Exchange element, also known as fin tubes products for Heat exchangers, enhancing the heat transfer performance of conventional tubes by attaching fins to the outer surface. These fins increase the surface area of the tube, allowing for better heat transfer efficiency.

At present, the most common and widely used Finned Tube is the partition wall type, and the design and calculation of other types of Heat Exchanger are often drawn from the partition wall type Heat Exchanger. As a general equipment,Heat Exchangers are classified according to their working principles and can be divided into partition type, hybrid type and regenerative type.

.jpg)

One-piece fins and externally attached fins

Fins attached to the tube may be integrally formed or attached externally.One-piece fins are formed by extruding or roll forming the fins directly onto the tube surface, while externally attached fins are separate components mechanically attached to the tube.

Fins can come in a variety of shapes and sizes depending on the specific requirements of the application. Common fin shapes include rectangular, circular, and oval. Fin size and spacing also play a role in determining heat transfer performance.

The finned tube is integrally rolled from an aluminum tube, with no contact thermal resistance, high strength, thermal shockand mechanical vibration, good thermal expansion performance, and has a considerable extended heat exchange surface.The effect of the Heat Exchanger is ahead of that of the string-sheet or wound-sheet Heat Exchanger.

The structure and characteristics of the finned tube Heat Exchanger

The finned tube is integrally rolled from an aluminum tube, with no contact thermal resistance, high strength, thermal shock and mechanical vibration, good thermal expansion performance, and has a considerable extended heat exchange surface.The effect of the Heat Exchanger is ahead of that of the string-sheet or wound-sheet Heat Exchanger.

The advantages of finned tube

Finned tubes offer several advantages over traditional smooth tubes. They increase heat transfer rates, increase thermal efficiency, reduce equipment size and weight, and enhance scale and corrosion resistance. Additionally, they provide better heat dissipation in space-constrained applications.

What are the advantages of stainless steel finned tube over carbon steel?

The two thermal conductivity are not much different, but the main differences are:

1.Stainless steel: beautiful in appearance, super corrosion resistance, and expensive, which is several times more expensivethan carbon steel.

2.Carbon steel: cheap but easy to oxidize and corrode in the air.

As for the specific use of stainless steel or cabon steel when designing the Heat Exchanger, it needs to be selectedaccording to the applicable place.

Application

Stainless steel fin tubes products are commonly used in various heat exchange applications, such as air conditioning systems, refrigeration systems, and heat recovery systems. They are particularly effective in situations where there is a significant temperature difference between the fluid inside the tube and the surrounding environment. You may need information about fin tubes manufacturers.

Overall, finned tubes are an effective solution for enhancing heat transfer performance in various industrial and commercial applications. They offer increased efficiency and improved performance, making them a popular choice in heat exchange systems.

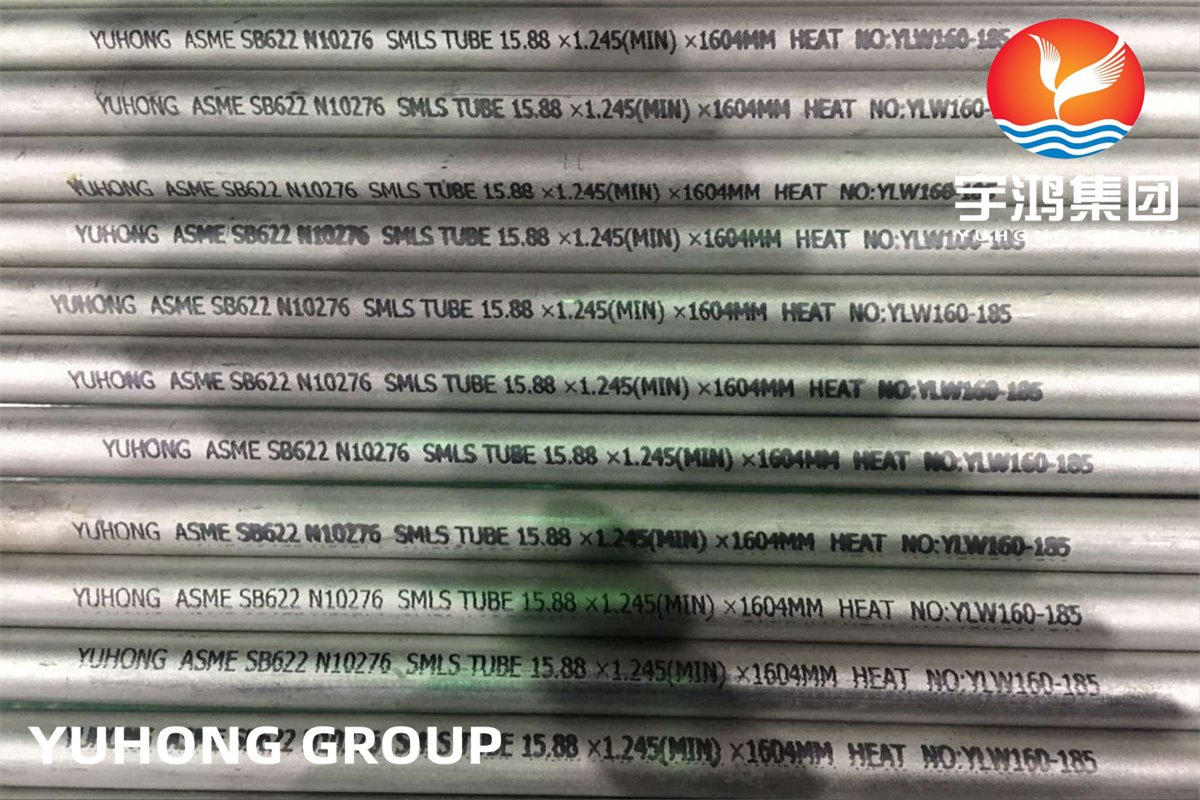

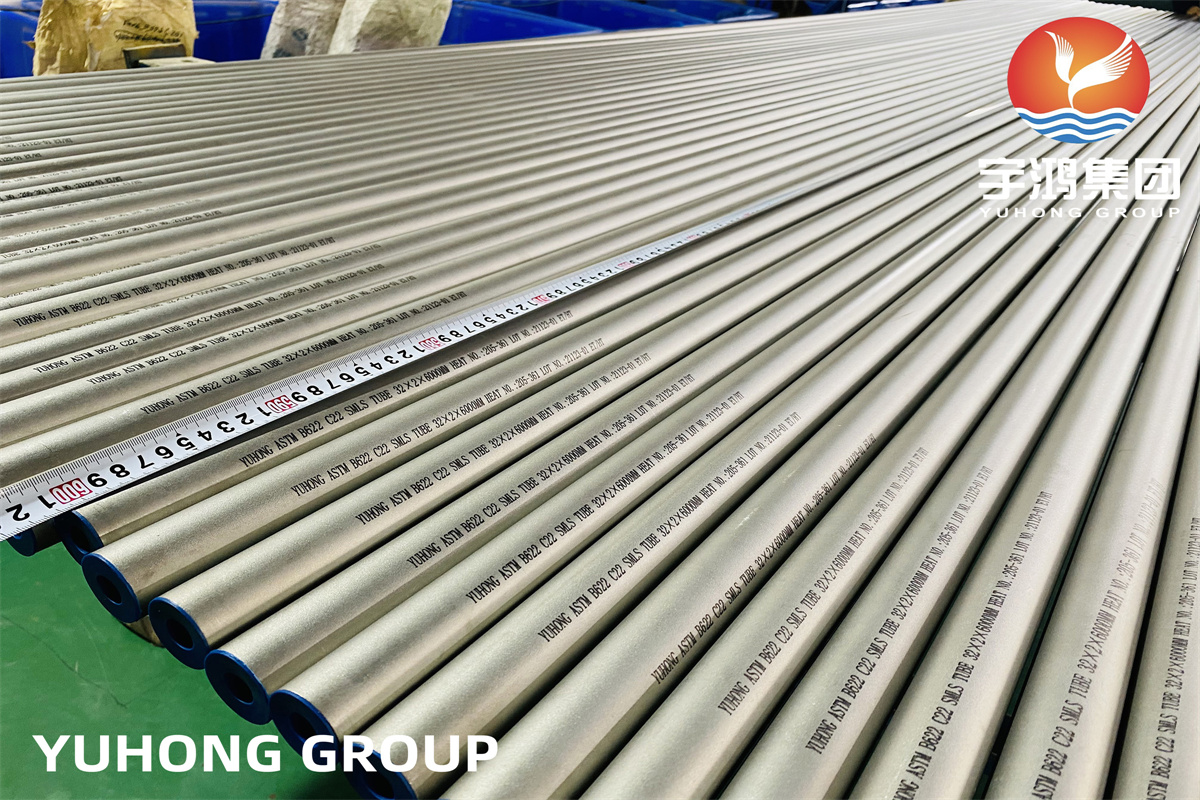

Learn more Yohong Group’s other alloy piping products: nickel alloy tubes, copper alloy tube, duplex tube, etc.

_.jpg)

English

English

.jpg)

_.jpg)

_副本.webp)