What is Heat Exchanger?

The heat exchanger is a system used to transfer heat between a source and a working fluid and it is used in both cooling and heating processes. Heat exchangers are widely used in space heating, refrigeration, air conditioning, power stations, chemical plants, petrochemical plants, petroleum refineries, natural-gas processing, and sewage treatment.

Types of Heat Exchanger

According to the heat transfer method: Partition heat exchanger / Regenerative heat exchanger / Fluid connection indirect heat exchanger / Direct contact heat exchanger / Compound heat exchanger

According to the use: Heater / Preheater / Superheater / Evaporator

According to the structure: Floating head heat exchanger / Fixed tube plate heat exchanger / U-shaped tube plate heat exchanger / Plate heat exchanger, etc.

The double tube heat exchanger is the simplest heat exchanger used in the industry. On the one hand, these heat exchangers are inexpensive to design and maintain, making them ideal for small industries. On the other hand, their low efficiency combined with the high space occupied on a large scale has led modern industries to use more efficient heat exchangers such as Shell-and-Tube or Plate.The following focuses on describing the difference between the Shell-and-Tube Heat Exchanger and Plate Heat Exchanger from different aspects.

Difference On Structure

Structure of Shell-and-Tube Heat Exchanger

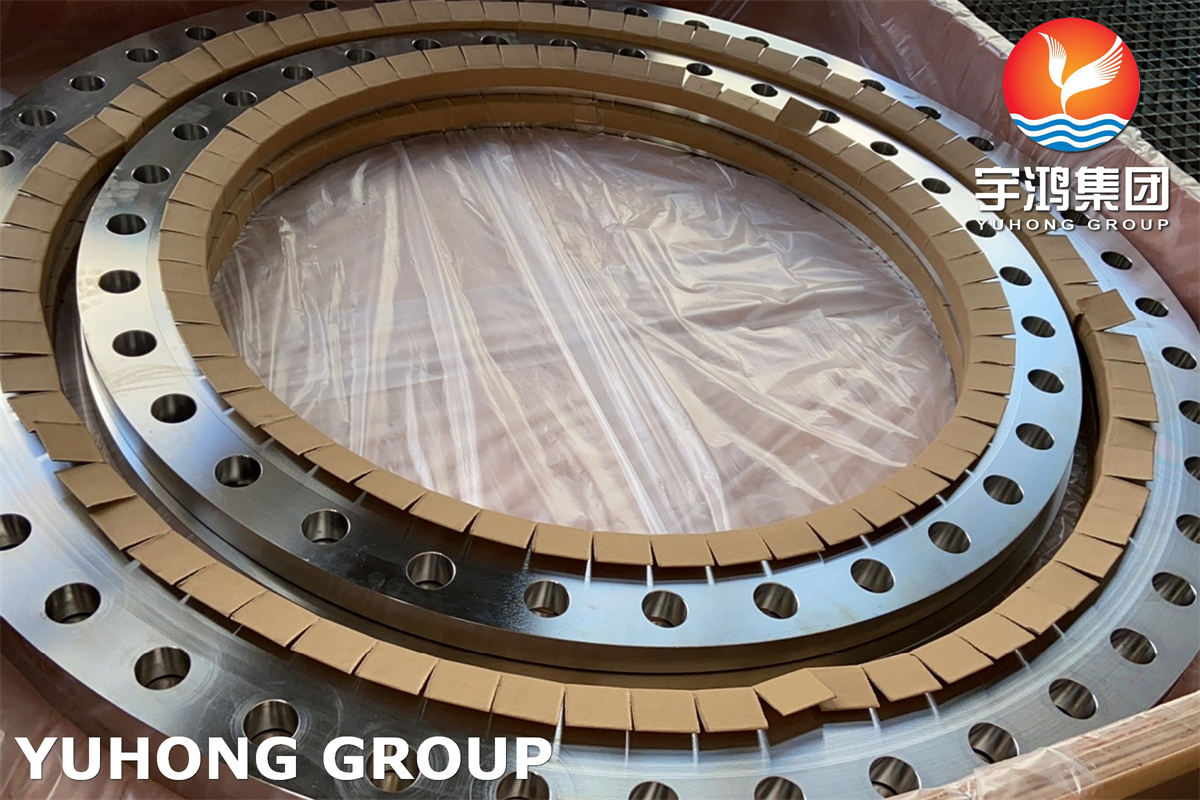

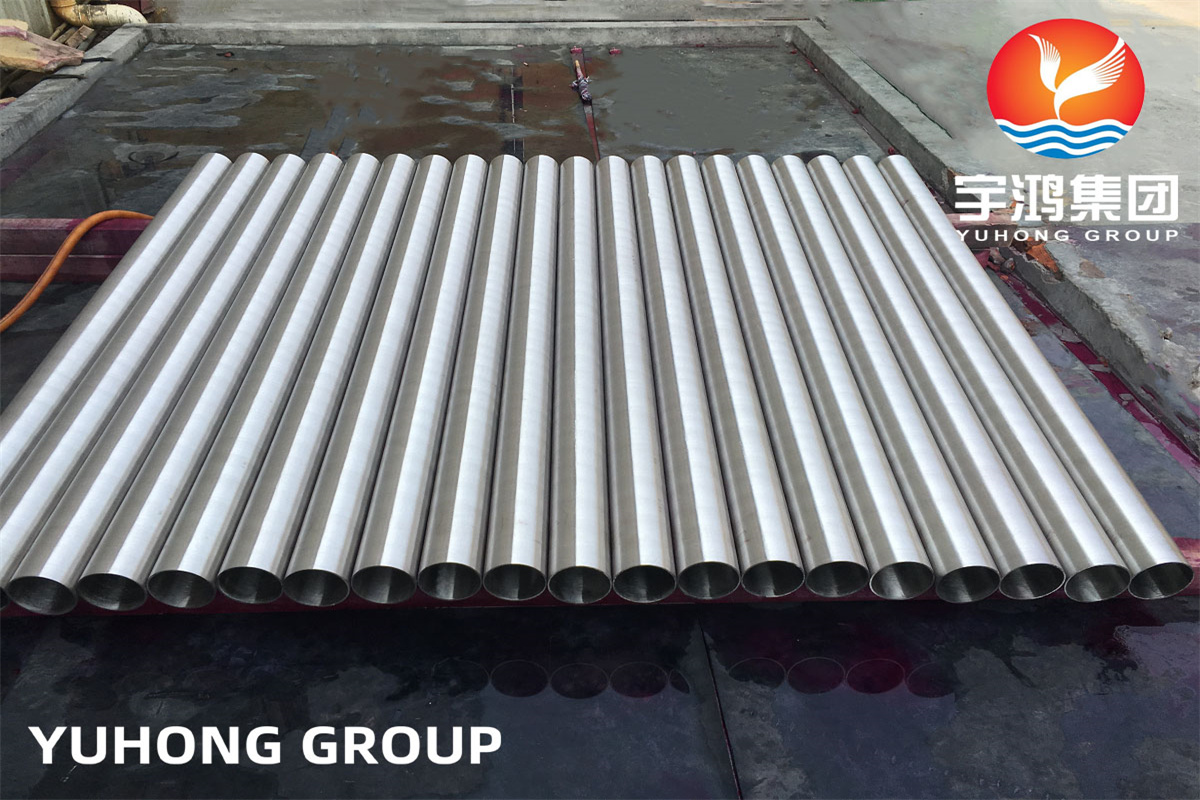

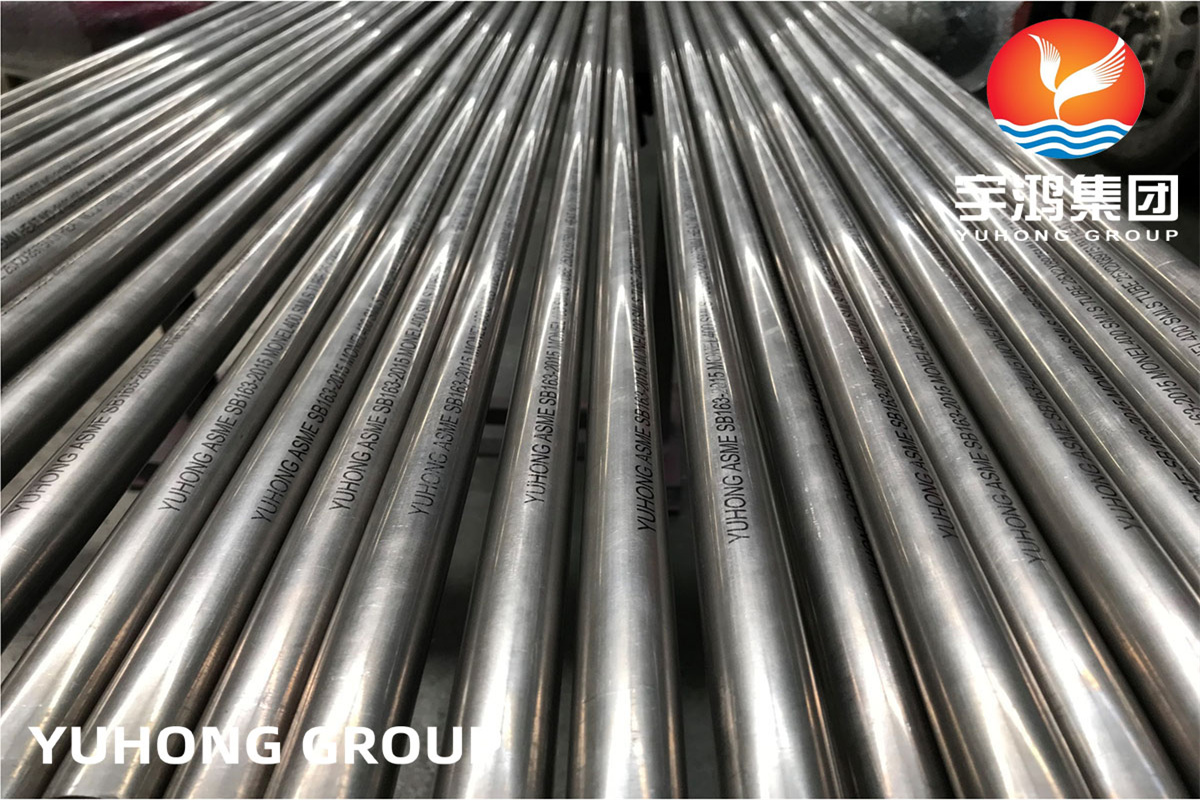

Shell-and-tube heat exchangers consist of shells, heat transfer tube bundles, tube sheets, baffles and tube boxes.The shell is mostly cylindrical,with tube bundles inside, and both ends of the tube bundles are fixed on the tube sheet There are two kinds of hot fluids and col fluids for heat transfer,one is the fluid inside the tube, which is called the tube side fluid;,the other is the fluid outside the tube, which is called the shell side fluid.

In order to improve the heat transfer coefficient of the fluid outside the tube, several baffles are usually arranged in the tube shell. The baffle can increase the flow velocity of the fluid in the shell side, make the fluid pass through the tube bundle multiple times according to the specified distance, and improve the turbulent flow of the fluid.

The heat exchange tubes can be arranged in equilateral triangles or squares on the tube sheet. The arrangement of equilateral triangles is compact, the fluid outside the tube is turbulent, and the heat transfer coefficient is large. The square arrangement facilitates cleaning the outside of the tube and is suitable for fluids prone to fouling.

Structure of Plate Heat Exchanger

The detachable plate heat exchanger is made of many corrugated plates stamped at a certain interval, sealed with gaskets around them, and lapped with frames and compression screws. The four corner holes of the plates and gaskets form the fluid distributors and headers. At the same time, the hot and cold fluids are reasonably separated so that they are separated on both sides of each plate. Flow in channels, heat exchange through plates.

Difference On Classification

Classification of Shell-and-Tube Heat Exchangers

The tube sheet of the fixed tube sheet heat exchanger is integrated with the tube bundles at both ends of the tube shell. The structure is simple, but it is only suitable for heat exchange operations where the temperature difference between hot and cold fluids is small, and the shell side does not require mechanical cleaning.

The tube sheet at one end of the tube bundle of the floating head heat exchanger can float freely, completely eliminating thermal stress, and the whole tube bundle can be pulled out from the shell, which is convenient for mechanical cleaning and maintenance. Floating head heat exchangers are widely used, but the structure is complicated and the cost is high.

Each tube of the U-shaped tube heat exchanger is bent into a U shape, and both ends are fixed on the same tube sheet in the upper and lower areas.The heat exchanger completely eliminates the thermal tress, and its structure is simpler than the floating head structure, but the tube side is not easy to clean.

The eddy current hot film heat exchanger adopts the latest eddy current hot film heat exchange technology to improve the heat exchange effect by changing the fluid motion state.

Classification of Plate Heat Exchangers

According to the size of the heat exchange area per unit space, the plate heat exchanger is a compact heat exchanger, which is mainly compared with the shell-and-tube heat exchanger.

According to the use of the process: Plate Heater, Plate Cooler, Plate Condenser, Plate Preheater.

According to the process combination: One-Way Plate Heat Exchangers and Multi-Way Plate Heat Exchangers.

According to the flow direction of the two media: Parallel Plate Heat Exchangers, Counter-Flow Plate Heat Exchangers and Cross-Flow Plate Heat Exchangers.

According to the gap size of the runner: Conventional Gap Plate Heat Exchangers and Wide Gap Plate Heat Exchangers.

According to the corrugated wear ,there are more detailed difference in plate heat exchangers, which will not be repeated:Corrugated form of plate heat exchangers.

According to whether it is a complete set of products: Single Plate Heat Exchanger and Plate Heat Exchanger Unit.

Difference On Feature

Features of Shell-and-Tube Heat Exchanger

High efficiency and energy saving, the heat transfer coefficient of the heat exchanger is 6000-8000W(m2-k).

Production of all stainless steel, long service life, up to 20 years.

The laminar flow is changed to turbulent flow that improves the heat transfer efficiency and reduces the thermal resistance.

Fast heat transfer, high temperature resistance (400 degrees Celsius), high pressure resistance (2.5 MPa).

Small footprint,compact structure,light weight, convenient installation, saving civil construction investment.

The design is flexible, the specifications are complete, the practicability is strong, and the money is saved.

Having wide range of application conditions,suitable for pressure, temperature range and heat exchange of various media.

Low maintenance cost, easy operation, long cleaning cycle and easy cleaning.

The use of nano-thermal film technology can significantly improve the heat transfer coefficient.

Widely used in thermal power, industrial and mining, petrochemical,urban central heating,food and medicine,energy electronics, mechanical light-industry and other fields.

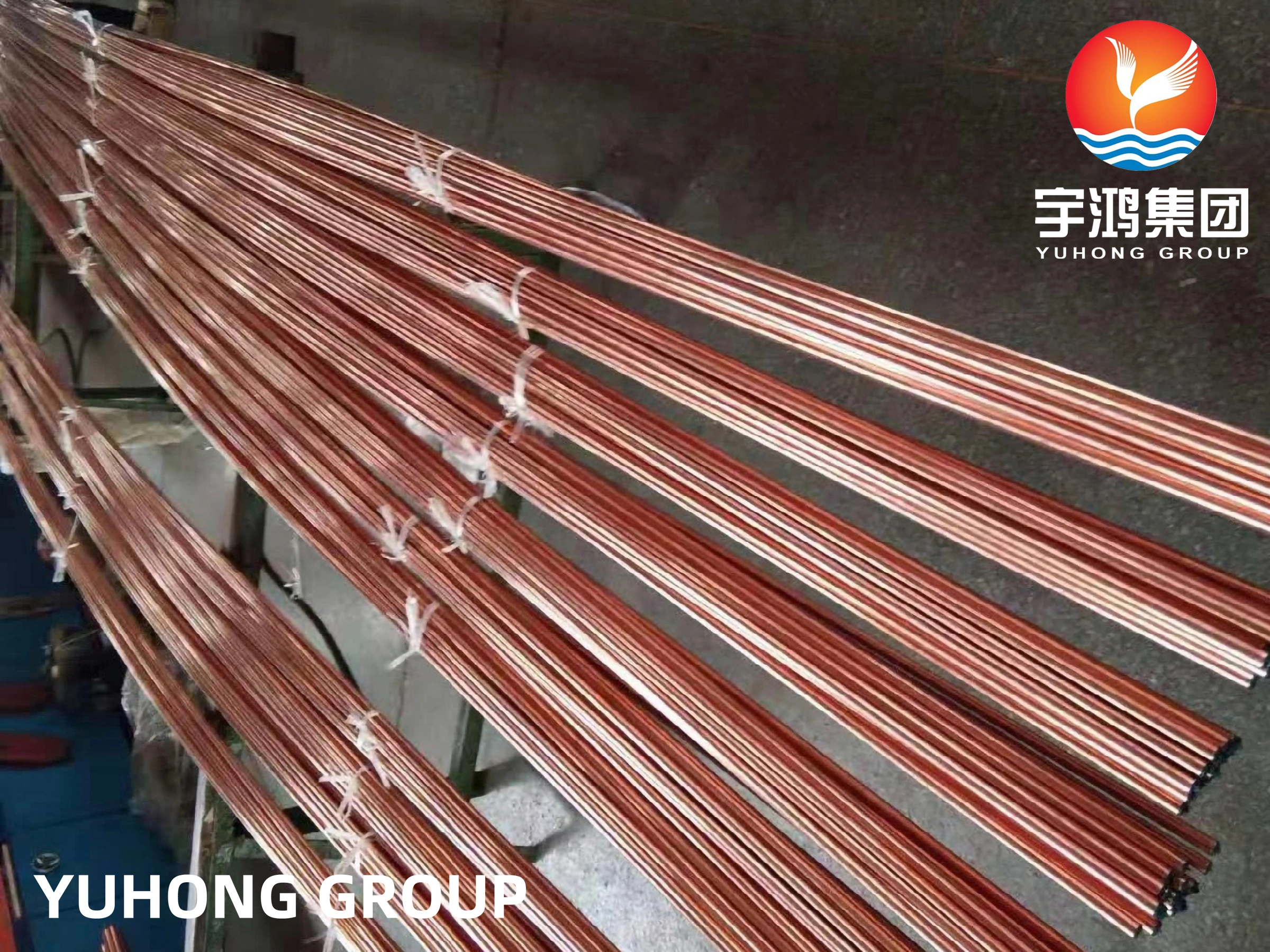

A copper tube with radiating fins is rolled on the outer surface of the heat transfer tube, with large heat transfer area and high thermal conductivity.

Suitable for low viscosity, clean heat transfer oil when the shell side fluid is oil.

Features of Plate Heat Exchanger

Since different corrugated plates are reversed, complex channels are formed, so that the fluid between the corrugated plates flows in a three dimensional swirling flow,so heat transfer The coefficient is relatively high, and the red is generally considered to be 3-5 times that of the shell-and-tube type.

The plate heat exchanger has a compact structure, and the heat transfer area per unit volume is 2-5 times that of the shell-and-tube heat exchanger. Unlike shell-and-tube heat exchangers, it does not require maintenance locations for tube bundle extraction. The footprint of the plate heat exchanger is about 1/5-1/8 of that of the shell-and-tube heat exchanger.

As long as a few plates are added or removed , the purpose of increasing or decreasing the heat transfer area can be achieved.

The plate thickness of the plate heat exchanger is only 0.4-0.8 mm, and the tube thickness of the shell-and-tube heat exchanger is 2.0-2.5 mm.Shell-and-tube heat exchangers are much heavier than plate heat exchanger frames.The plate heat exchanger generally only accounts for about 1/5 of the weight of the shell.

The material of the plate heat exchanger is the same, the heat exchange area is the same, and the price is 40%-60% lower than that of the shell-and-tube heat exchanger.

The heat transfer plate of the plate heat exchanger is stamped and formed, with a high degree of standardization and can be mass-produced.

As long as the compression bolts of the frame-plate heat exchanger are loosened, the tube bundle of the plate heat exchanger can be loosened, and the plate heat exchanger can be removed for mechanical cleaning. This is very convenient for the heat exchange process of equipment that needs to be cleaned frequently.

In a plate heat exchanger, only the shell of the heat exchange plate is exposed to the atmosphere, the heat loss is negligible, and no insulation measures are required.

_recompress.jpg)

English

English

_recompress.jpg)