Stainless steel is mainly distinguished from carbon steel by the fact that stainless steel does not have any artificially added alloy elements other than carbon content. Carbon steel generally does not have corrosion resistance. It has higher hardness than pure iron.

Understanding stainless steel tubing and carbon steel pipe fittings

There are many types of stainless steel, which refers to alloy steel with a chromium content greater than or equal to 13% that does not rust in the atmosphere. There are austenitic stainless steel, ferritic stainless steel, martensitic stainless steel, etc. Stainless steel generally does not have magnetism, but it is not absolute. Austenitic stainless steel does not have magnetism, but ferritic stainless steel does, although it is relatively weak. Different stainless steels have different corrosion resistance capabilities and different resistance to different media.

Carbon steel pipe fittings are generally distinguished from stainless steel by their corrosion resistance. However, stainless steel, with its excellent performance, plays an irreplaceable role in practical applications, such as some heat-resistant stainless steel or stainless steel with excellent surface properties widely used in decorative materials, as well as stainless steel with excellent mechanical properties used in various manufacturing industries. Ordinary steel is carbon steel, which is an iron-carbon alloy. Depending on the carbon content, it is divided into low carbon steel, medium carbon steel, and cast iron. Low carbon steel, commonly known as wrought iron or pure iron, has a carbon content of less than 0.2%; steel has a carbon content between 0.2% and 1.7%; and pig iron has a carbon content above 1.7%.

Differences between stainless steel tubing and carbon steel pipe fittings

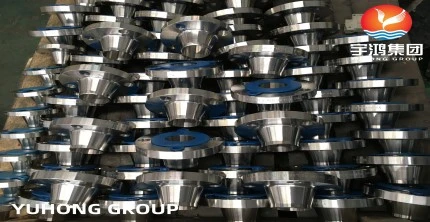

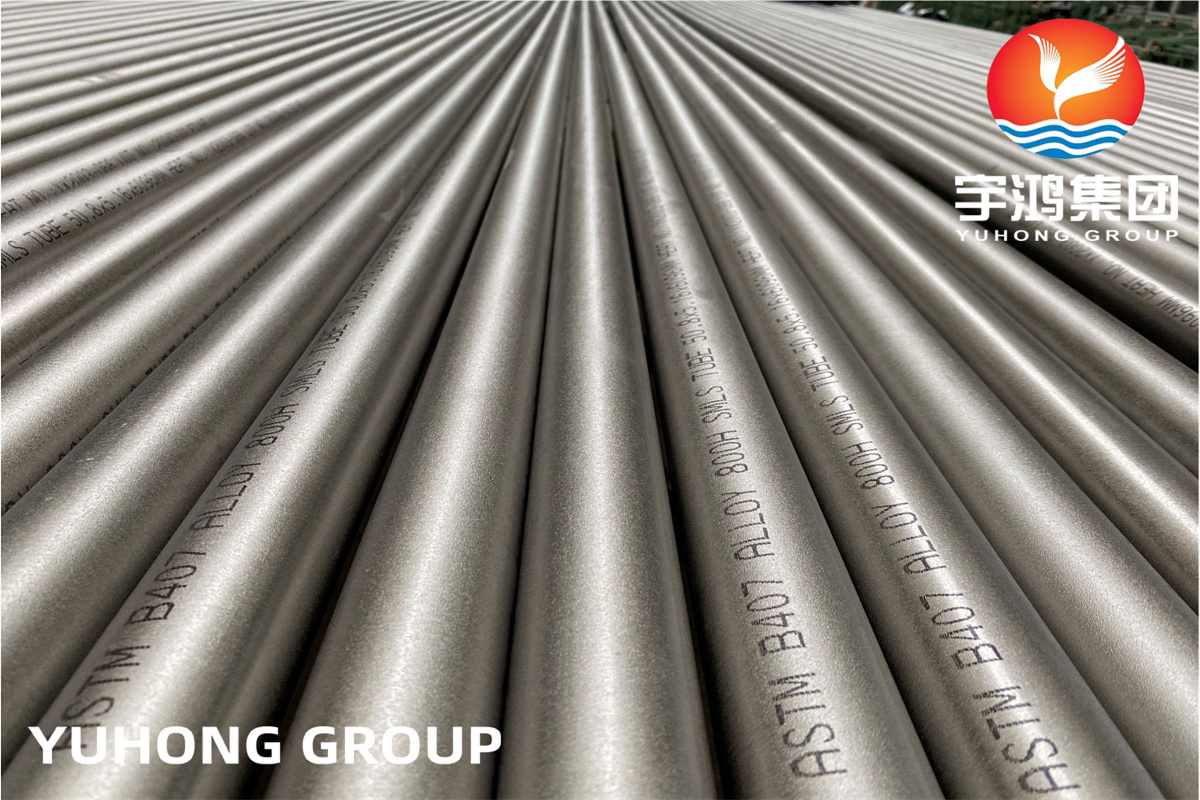

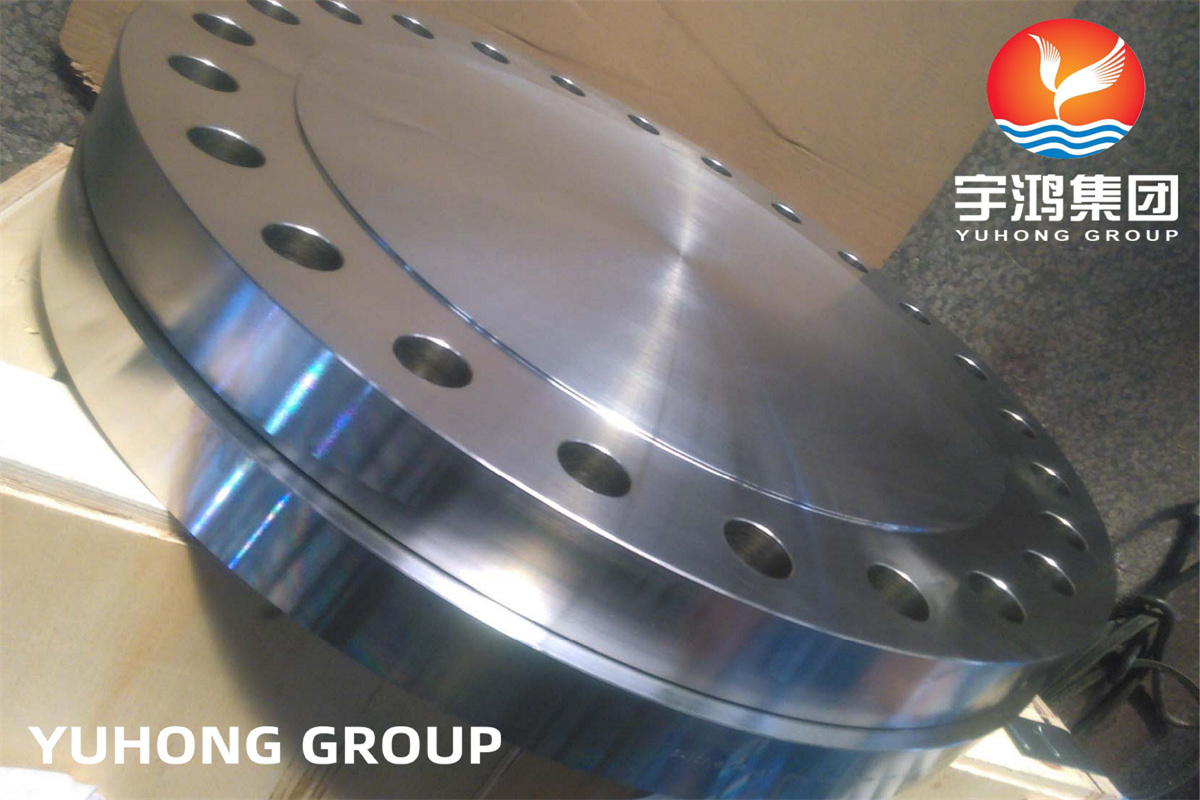

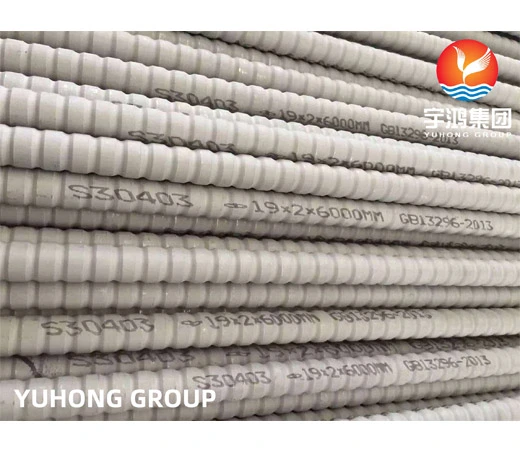

Steel with a chromium content greater than 12.5% is called stainless steel, which has a higher resistance to corrosion from external media (acid, alkali, salt). Depending on the internal structure of the steel, stainless steel tubing can be divided into martensitic type, ferritic type, austenitic type, ferrite-austenite dual phase type, and precipitation hardening type stainless steel.

Austenitic and martensitic stainless steels are the two main types we encounter in daily life. Typical grades of austenitic stainless steel are 0Cr18Ni9, also known as "304", and 1Cr18Ni9Ti. Martensitic stainless steels are used in the production of knives and shears, and the main grades include 2Cr13, 3Cr13, 6Cr13, 7Cr17, etc.

Due to the differences in the composition of these two types of stainless steel, their internal metallic microstructures are also different.

Austenitic stainless steel pipes&tubes are characterized by the addition of higher chromium and nickel content in the steel (chromium content is around 18%, nickel content is above 4%), resulting in a microstructure called austenite, which is non-magnetic and cannot be attracted by magnets. It is commonly used for decorative materials such as stainless steel pipes, towel racks, tableware, and stoves.

Martensitic stainless steel is used for making knives and shears. Because knives and shears have the function of cutting objects, they must have sharpness, and to achieve sharpness, they must have a certain hardness. This type of stainless steel must undergo heat treatment to transform its internal structure and increase hardness before it can be used for knives and shears. However, the internal structure of this type of stainless steel is tempered martensite, which is magnetic and can be attracted by magnets. Therefore, whether it is stainless steel pipes&tubes or not cannot simply be determined by whether it is magnetic or not.

English

English

_副本.webp)