A shell-and-tube heat exchanger is the most common type of heat exchanger in oil refineries and other large chemical processes, and is suited for higher-pressure applications.

It is a class of heat exchanger designs. This type of heat exchanger consists of a shell (a large pressure vessel) with a bundle of tubes inside it.The set of tubes is called a tube bundle, one fluid runs through the tubes, and another fluid flows over the tubes (through the shell) to transfer heat between the two fluids. Tube bundle can be composed of several types of tubes: plain, longitudinally finned, etc.

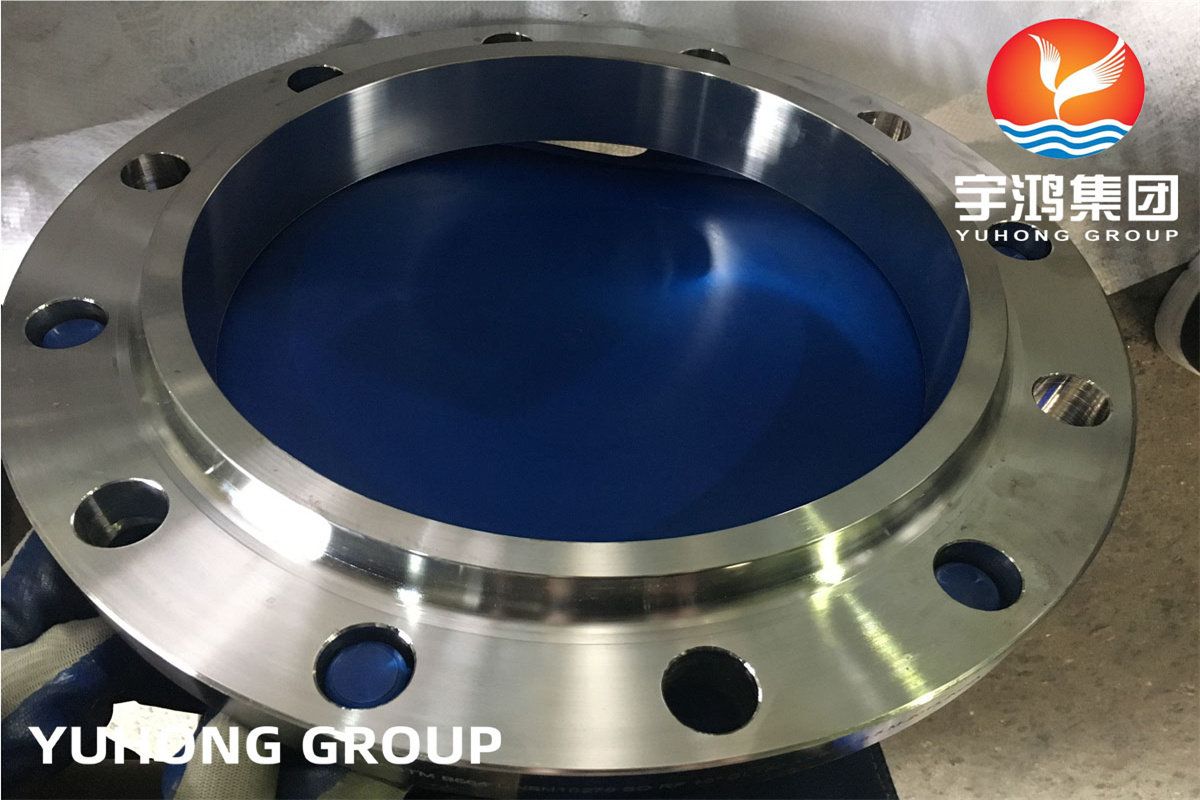

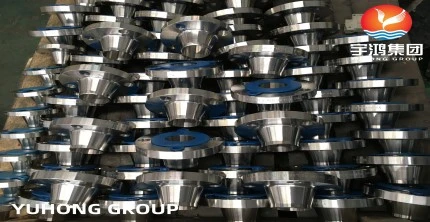

There can be many variations on the shell-and tube-design. Typically, the ends of each tube are connected to plenums through holes in tubesheets. The tubes may be straight or bent in the shape of a U.

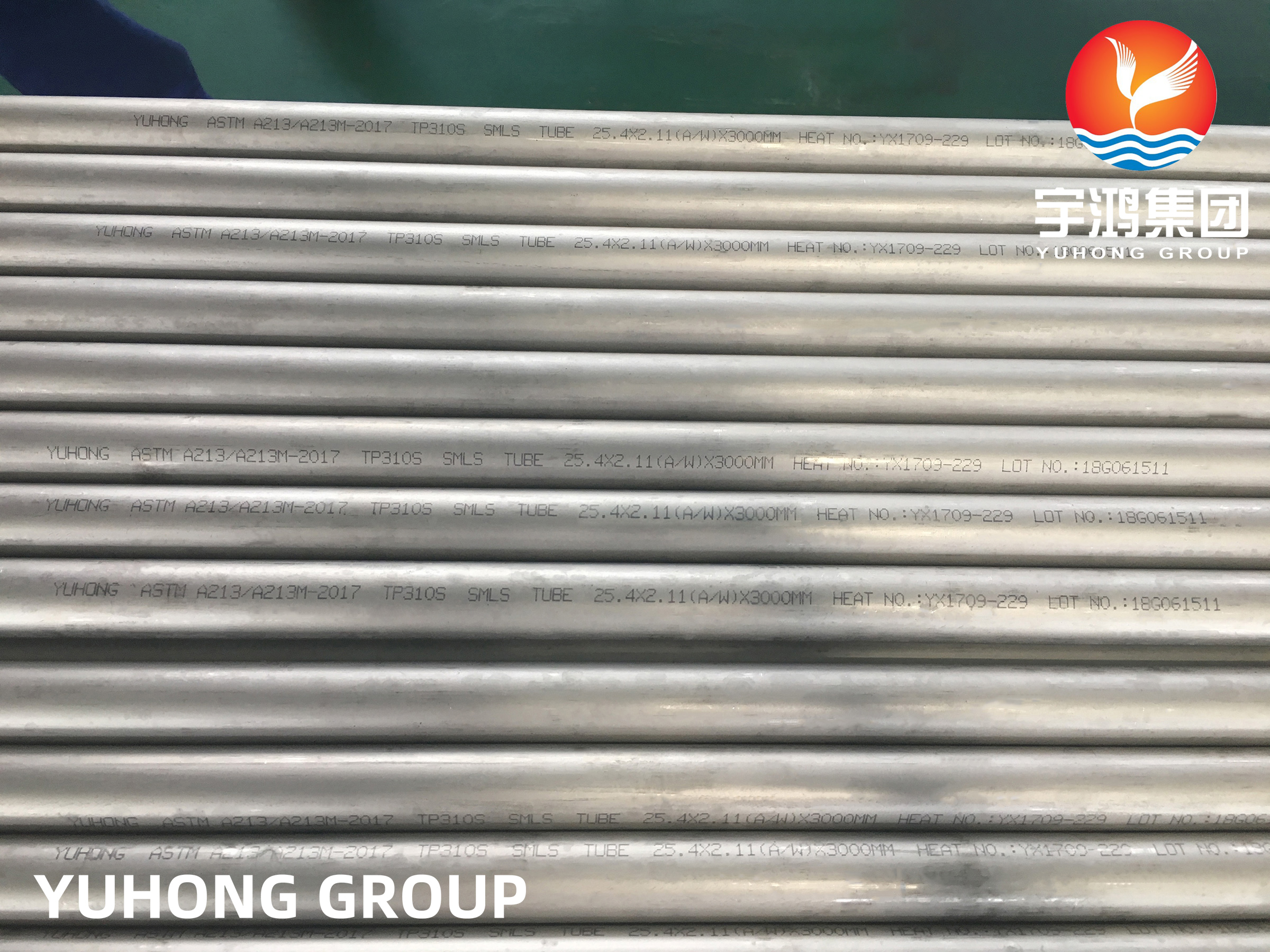

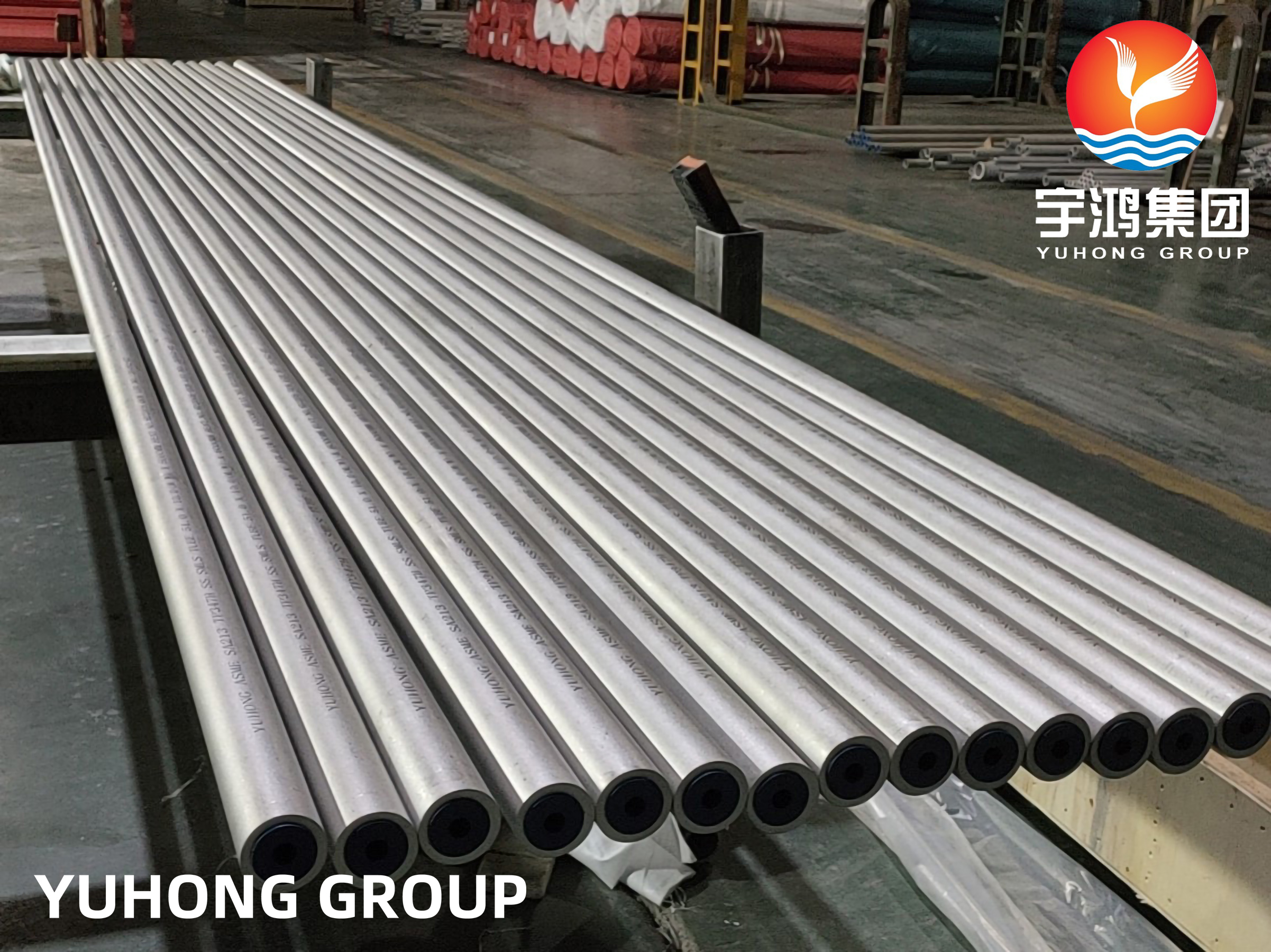

YuHong Group is a heat exchanger tube manufacturer and supplier according to the drawing of clients. Of course, YuHong can also provide tube bundles, tubesheets, baffles and tubes for heat exchanger.

.jpg)

Theory and application

Two fluids with different starting temperatures flow through the heat exchanger. One flows through the tube (tube side) and the other flows outside the tube but inside the shell (shell side). The fluid on the shell or tube side can be liquid or gas.Heat is transferred through the tube wall from one fluid to another, from the tube side to the shell side, and vice versa.

In order to transfer heat efficiently, a large heat transfer area needs to be used, resulting in the use of many tubes. In this way, the waste heat can be used.

Heat exchangers can be divided into 3 types: U tube heat exchanger, Single-phase straight tube heat exchanger , Two-phase straight tube heat exchanger. Two-phase heat exchangers can be used to heat a liquid to boil it into a gas (vapor), called boilers; or to cool the vapors and condense it into a liquid (called condensers), with the phase change usually occurring on the shell side. Boilers in steam engine locomotives are typically large, usually cylindrically-shaped shell-and-tube heat exchangers.

They are also used in liquid-cooled chillers for transferring heat between the refrigerant and the water in both the evaporator and condenser, and in air-cooled chillers for only the evaporator.

.jpg)

Tube material

To be able to transfer heat well, the tube material should have good thermal conductivity. The tube material also should be compatible with both the shell-and-tube side fluids for long periods under the operating conditions (temperatures, pressures, pH, etc.) to minimize deterioration such as corrosion.

Therefore, it is necessary to choose strong, thermal conductivity, corrosion resistance of high-quality pipes, usually metal materials, including copper alloy, stainless steel, carbon steel, non-ferrous copper alloy, inconel, nickel, Hasselloy and so on.

With our expertise and commitment to quality, YuHong Group delivers exchanger tubes that meet the highest industry standards, ensuring long-lasting and cost-effective solutions for your specific needs.

.jpg)

English

English

.jpg)

.jpg)

.jpg)