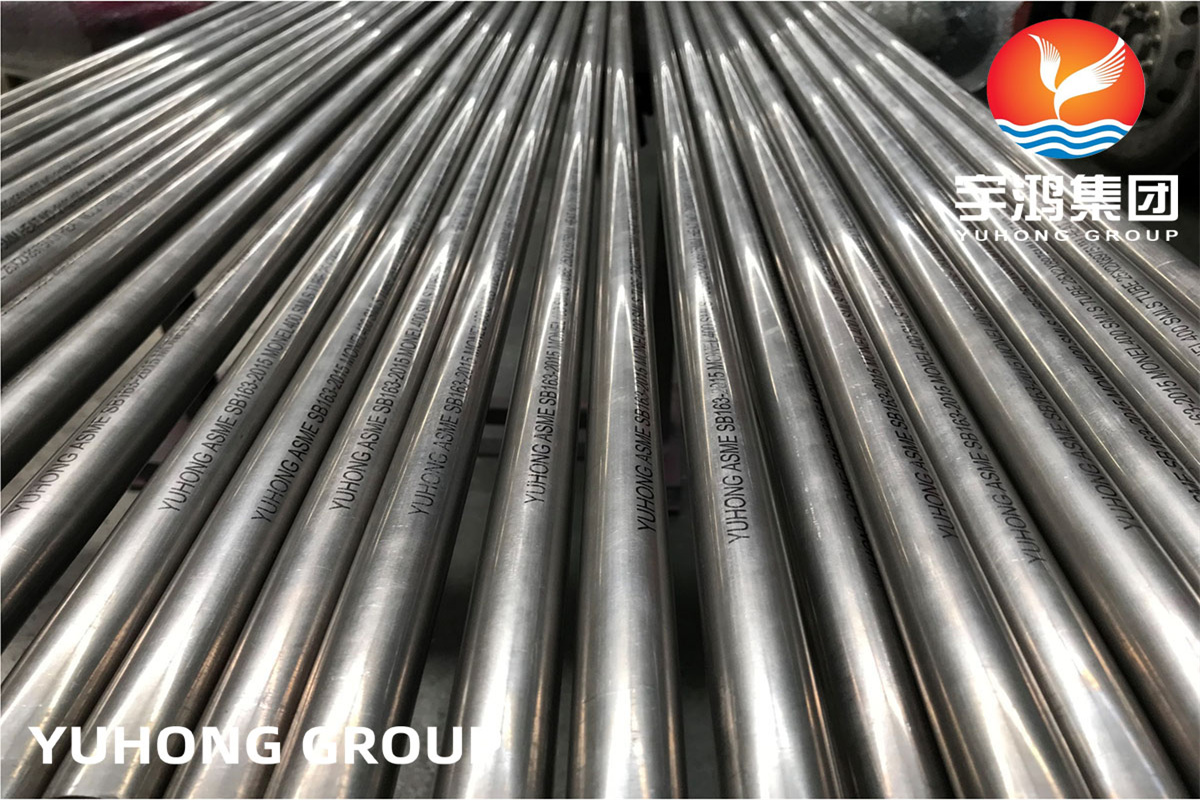

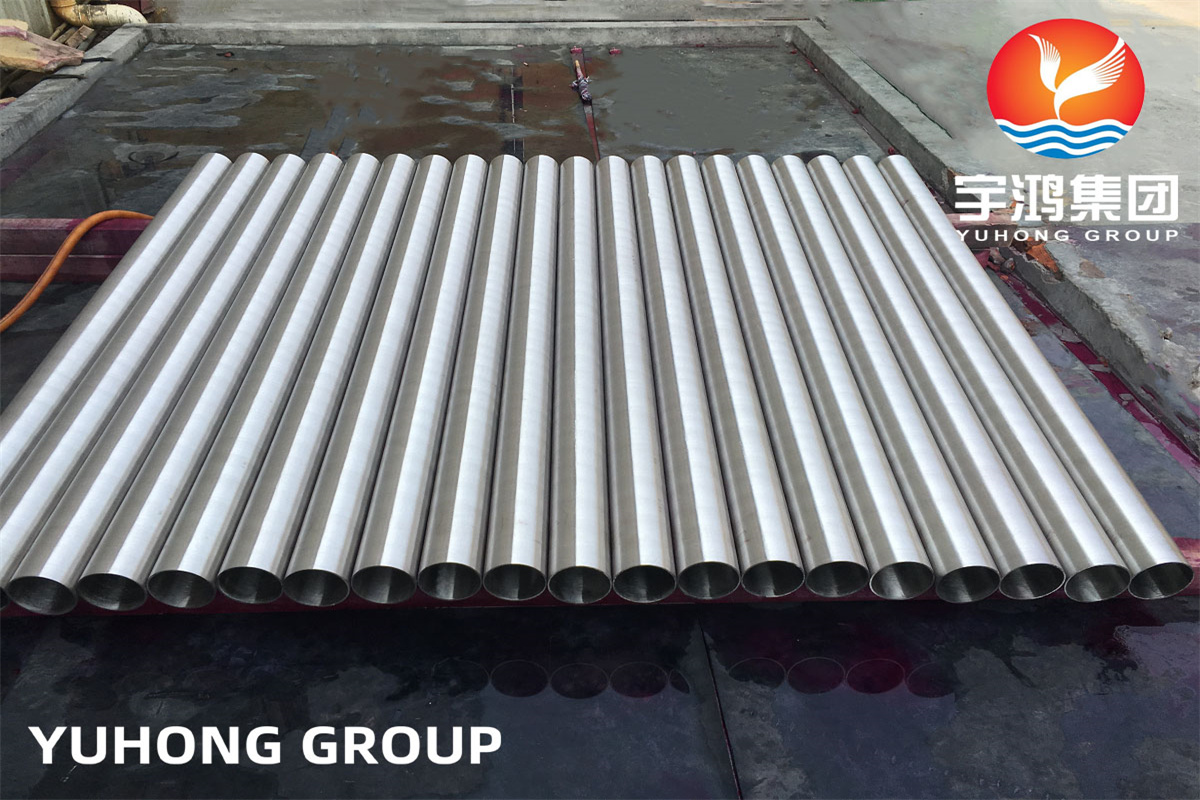

For 304 stainless tubes, the Ni element in their composition is very important, directly determining the corrosion resistance and value of 304 stainless steel. The most important elements in 304 are Ni and Cr, but not limited to these two elements. Specific requirements are specified by product standards. A common industry judgment holds that as long as the Ni content is greater than 8% and the Cr content is greater than 18%, it can be considered as 304 stainless. This is also why the industry refers to such stainless as 18/8 stainless. In fact, the relevant product standards have very clear regulations on 304, and these product standards have some differences for different shapes of stainless.

Factors affecting the price of 304 stainless tubes

Those who do stainless business will pay attention to the price of stainless tubes, and the price of 304 stainless tubes is also related to thickness. What are the thickness factors that affect the price of tubes?

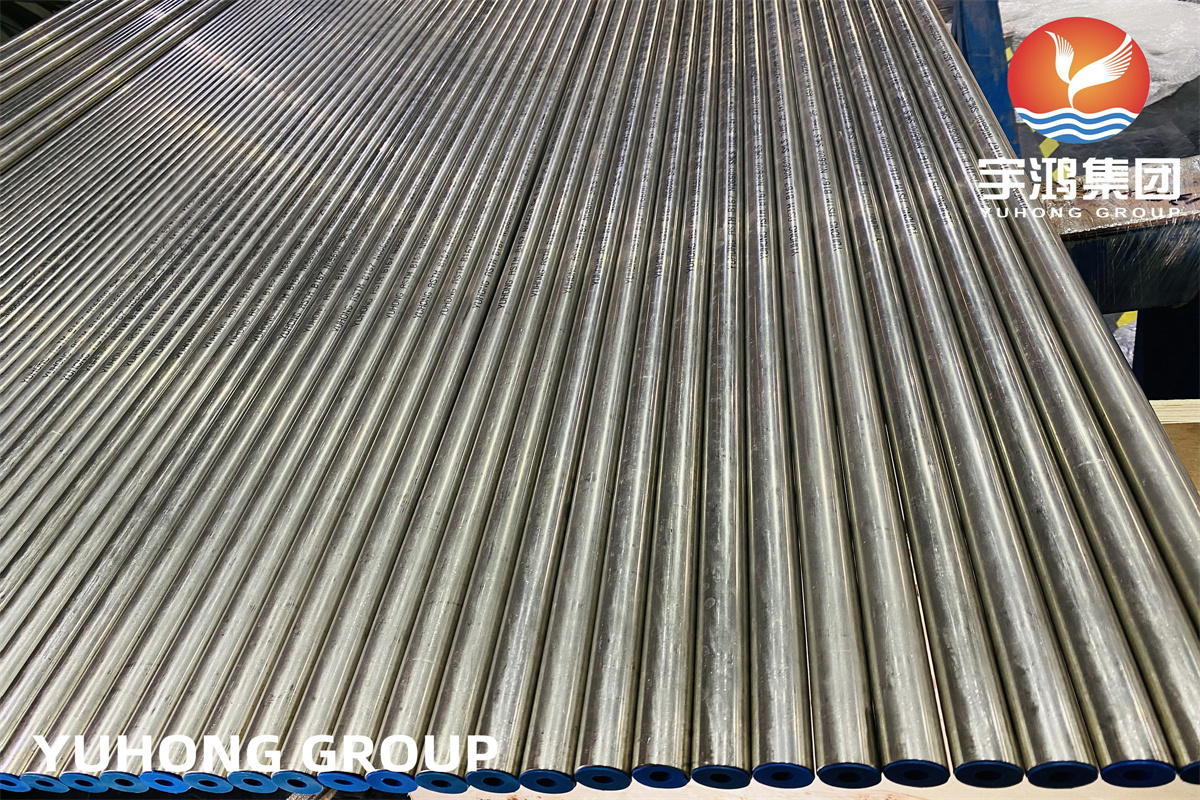

Thickness of the steel strip

The thickness of the steel strip has different rolling fees. The thinner the thickness, the more expensive the rolling and processing fees required. Additionally, thicknesses that are not commonly used or thicker ones will also increase the rolling fees, which directly leads to an increase in the price of stainless tubes.

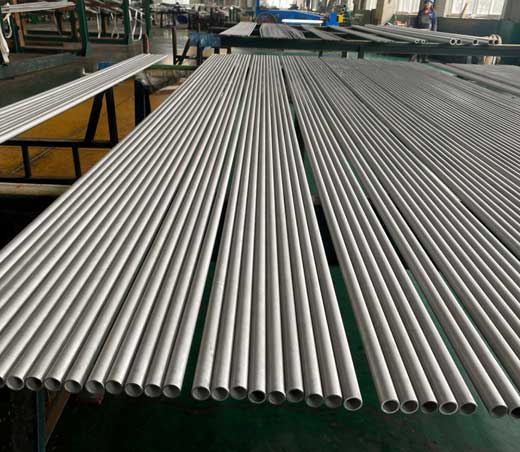

Thickness affects the yield rate of stainless tubes

Each thickness of the tube has its own suitable thickness range. Generally, in the manufacturer's workshop, thicknesses of 0.40mm and above are more popular, as tubes of this thickness have a higher yield rate during tube-making and polishing. However, the reality is that customer demand is constantly changing, and there are also some thin tubes, such as 0.31mm thick 304 stainless tubes. The thickness of this type of steel strip is relatively thin, with higher requirements for tube-making or polishing, resulting in a lower yield rate for stainless tubes, higher waste rates, and higher costs.

Is harder 304 stainless tubes better?

People often ask, "Are stainless tubes better if they are harder?" Many users believe that the harder the stainless tubes, the better the quality, especially for making stainless security windows, railings, and handrails, as they feel that higher tube hardness makes them more solid. However, is this really the case?

Before addressing this issue, let us first understand the element types contained in stainless tubes. Stainless tubes contain metal elements such as nickel, chromium, copper, carbon, sulfur, phosphorus, and manganese. The element that determines the hardness of the stainless tube is carbon, which has the main characteristic of making objects harder. With an increase in carbon content, the hardness of stainless tubes will also increase. However, carbon is a double-edged sword, and as the carbon content increases, the plasticity and toughness of the stainless tube will decrease, and welding, cold bending, and corrosion resistance will also decrease significantly. The higher the carbon content, the lower the content of other metals, so understanding the characteristics of the stainless tube is key to purchasing 304 stainless tubes in a knowledgeable way.

English

English

_副本.webp)

_副本.webp)