In the world of electrical engineering, the choice of materials plays a crucial role in determining the efficiency, reliability, and overall performance of electrical systems. Copper alloy tubes, with their excellent conductivity and versatility, have emerged as key components in various applications within the realm of electrical engineering. This blog explores the diverse ways in which copper alloy tubes contribute to conducting brilliance in electrical systems.

Seamless Conductivity: Enhancing Power Transmission

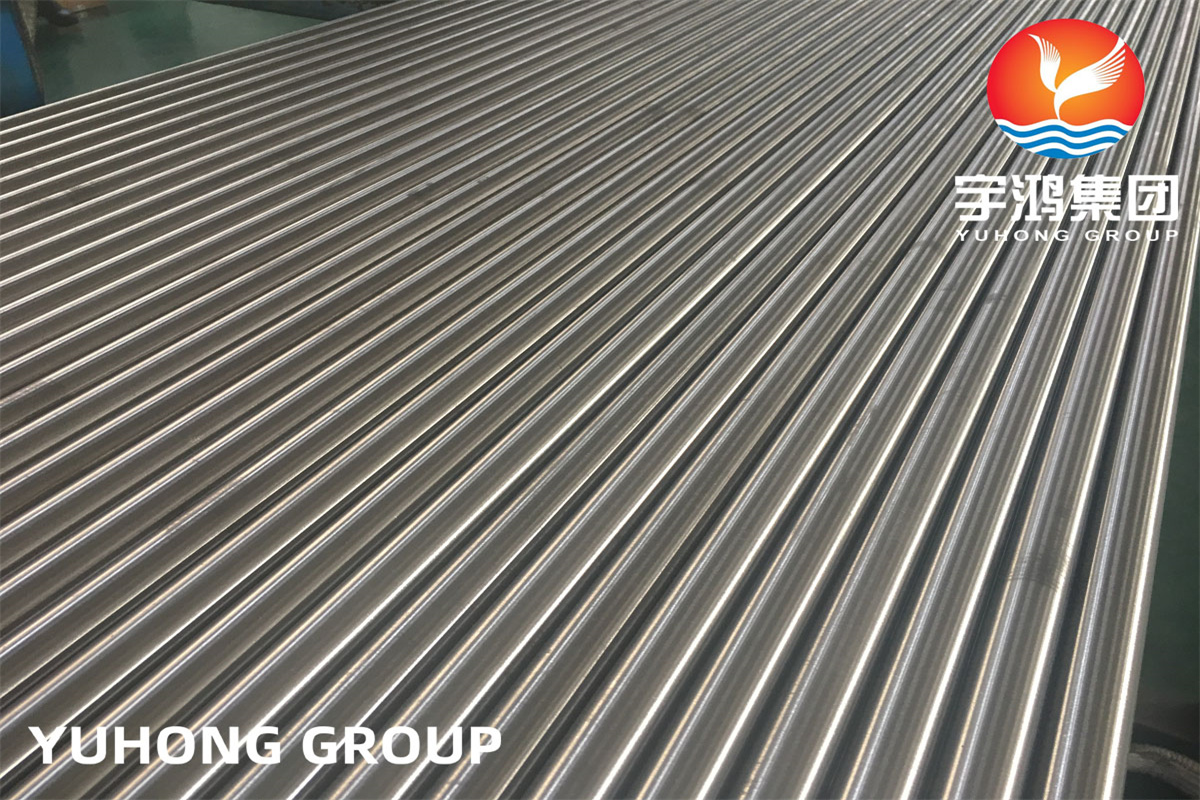

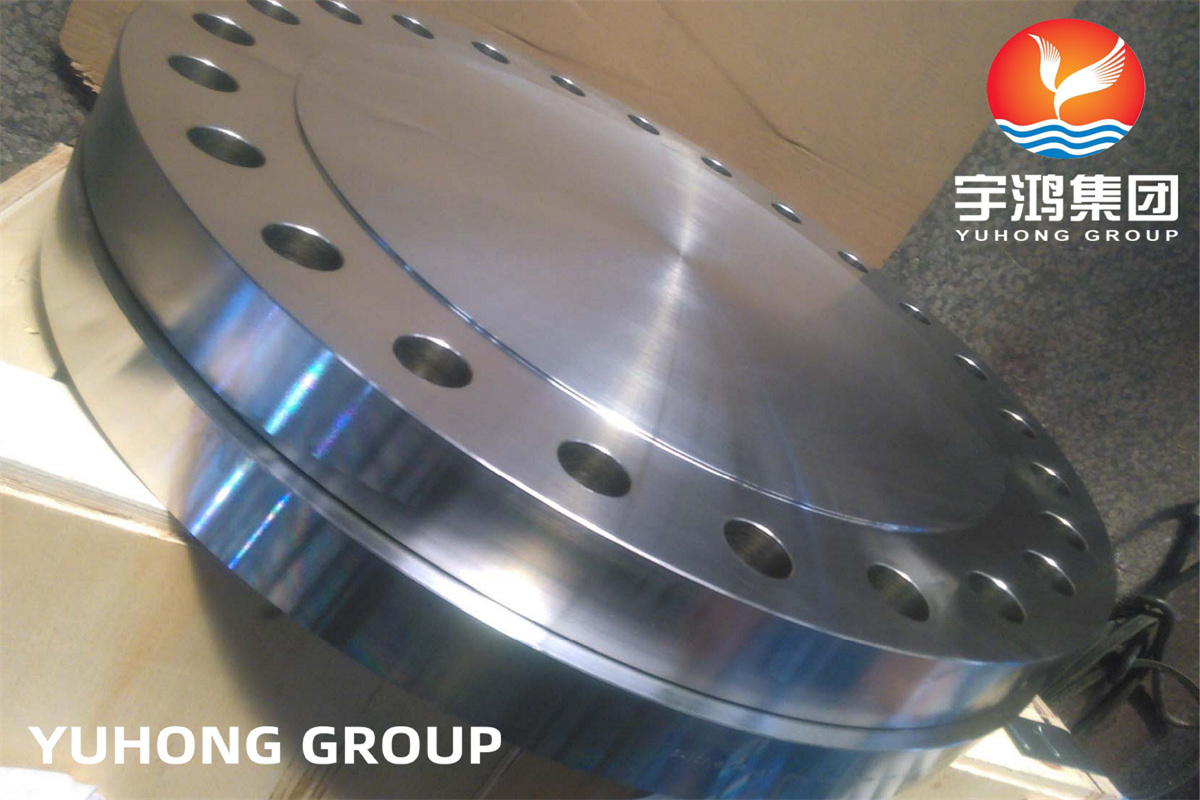

Copper alloy tubes are celebrated for their superior conductivity, making them ideal candidates for power transmission applications. The seamless flow of electrical currents through these tubes minimizes energy loss, ensuring that power is transmitted efficiently across various electrical grids. From substations to power lines, copper alloy tubes form the backbone of reliable and high-performance electrical transmission systems.

Wiring Solutions: Copper Alloy Tubes in Building Electrical Networks

In the construction and electrical wiring of buildings, copper alloy tubes play a pivotal role in ensuring a safe and efficient flow of electricity. The tubes are often used in the manufacturing of conductive wires, providing a reliable medium for electrical currents to travel through walls and infrastructure. Their durability and resistance to corrosion make them a preferred choice for building electrical networks that demand longevity and stability.

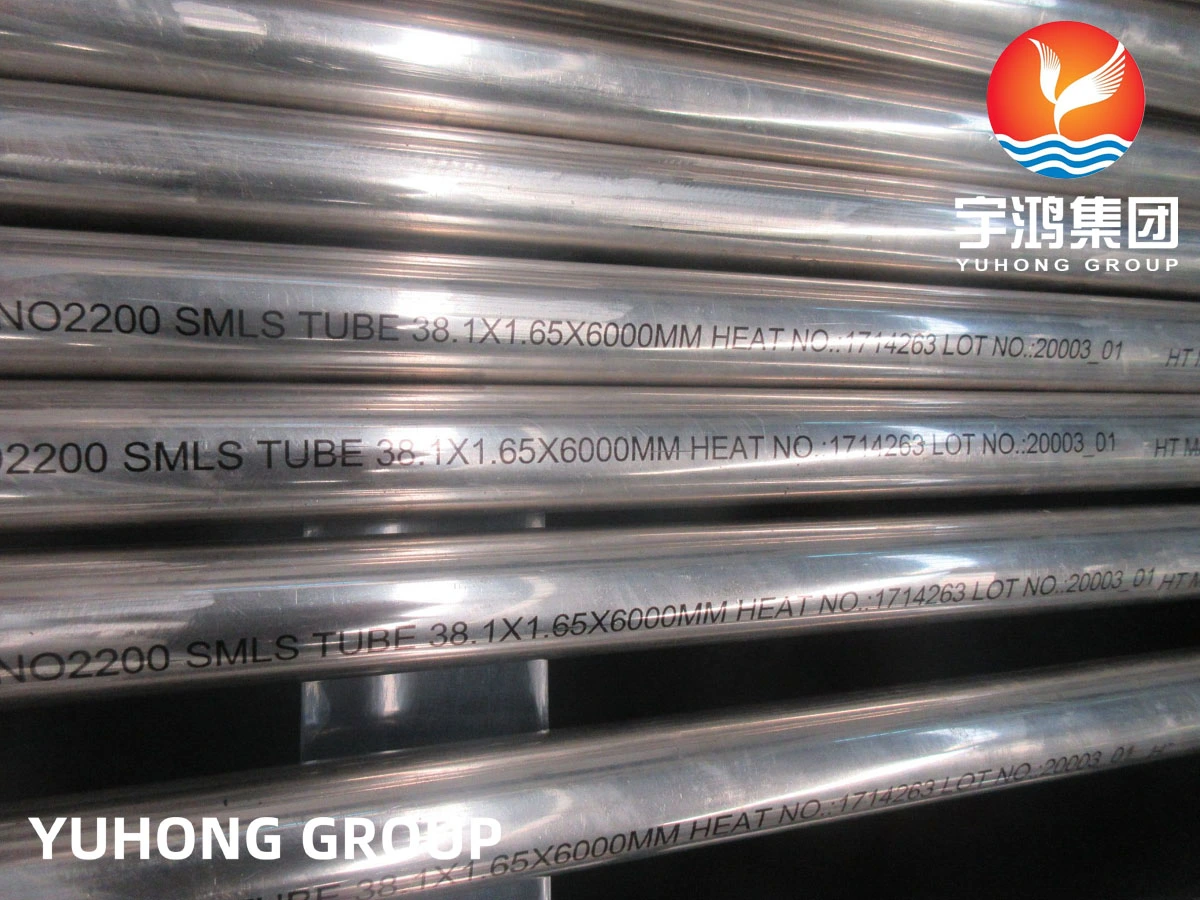

Thermal Management: Copper Alloy Tubes in Heat Exchangers and Cooling Systems

Beyond their electrical conductivity, copper alloy tubes are also renowned for their excellent thermal conductivity. This property finds application in electrical systems where effective heat dissipation is crucial. Copper alloy tubes are commonly integrated into heat exchangers and cooling systems, ensuring that electrical components remain within their optimal temperature range for efficient operation.

Electronics Manufacturing: Microscopic Marvels of Copper Alloy Tubes

At the microscopic level, copper alloy tubes are indispensable in the manufacturing of electronic components. From transistors to microchips, these tubes provide the pathways for intricate circuits within electronic devices. Their malleability and conductivity make them essential in the miniaturized world of electronics, contributing to the seamless functioning of devices we use daily.

Renewable Energy Revolution: Copper Alloy Tubes in Solar Panels

As the world embraces renewable energy, copper alloy tubes find themselves at the forefront of innovation in solar power generation. These tubes play a crucial role in the construction of solar panels, facilitating the efficient conversion of sunlight into electrical energy. Their conductivity and resistance to environmental elements make copper alloy tubes an integral part of the renewable energy revolution.

In the realm of electrical engineering, where efficiency and reliability are paramount, copper alloy tubes stand out as a shining example of conducting brilliance. From power transmission and building wiring to thermal management, electronics manufacturing, and renewable energy, these tubes showcase their versatility across diverse applications. As electrical systems evolve and the demand for efficient and sustainable solutions grows, copper alloy tubes continue to illuminate the path towards a future powered by reliable and high-performance electrical engineering.

English

English

_副本.webp)