We may be deceived when buying pipe stainless due to lack of understanding. Today we will tell you how to identify the hardness of stainless steel. Hardness is also one of the factors affecting the price of stainless steel. At the same time, we will show you the price composition of pipe stainless.

Methods for identifying the hardness of pipe stainless

When judging the quality of stainless steel products, its hardness is a very important parameter. It will affect its service life and performance, so it is very important. The hardness of pipe stainless is usually measured by Brinell hardness, Rockwell hardness, and Vickers hardness. Its price will be affected by the hardness of the product. The details are described below.

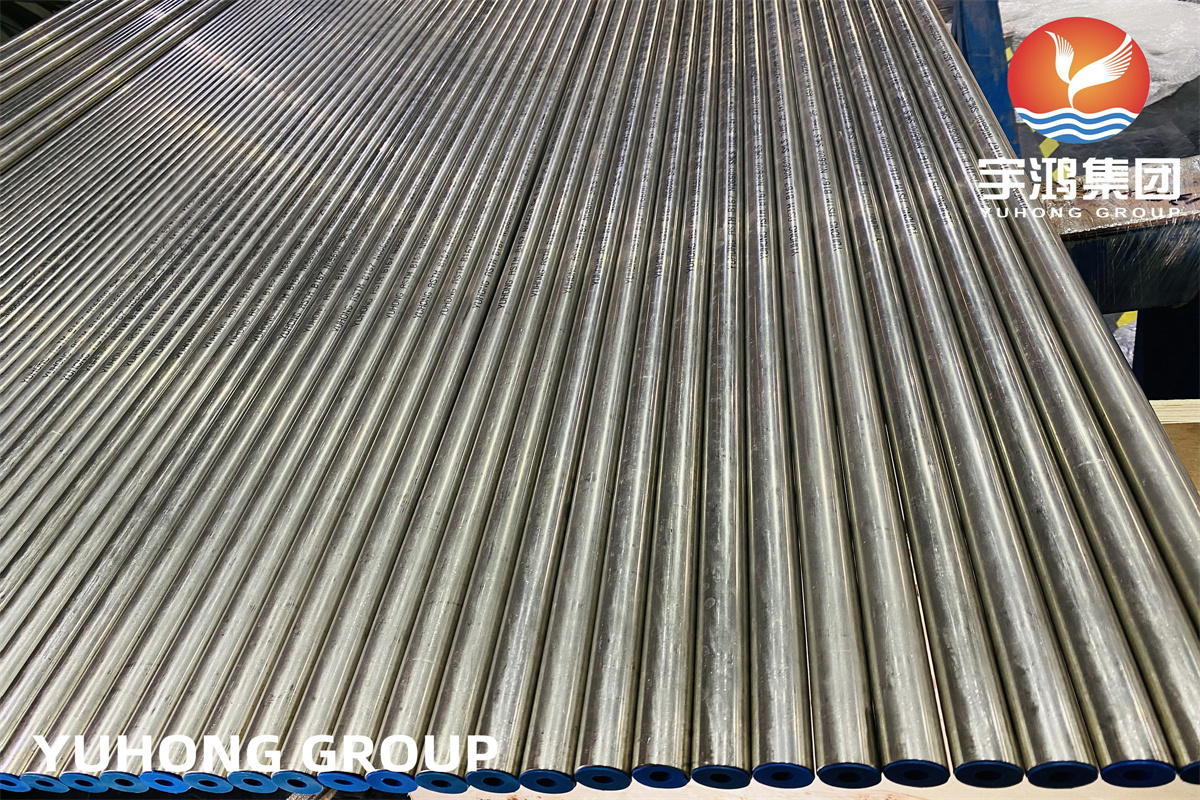

The Vickers hardness tester can be used for annealed pipe stainless with an inner diameter above 6.0mm and a wall thickness below 13mm. This method is quick and easy, suitable for rapid non-destructive qualification inspection.

For pipe stainless with an inner diameter greater than 30mm and a wall thickness greater than 12mm, the Rockwell hardness tester should be used to test the hardness of HRB and HRC. If the inner diameter is greater than 30mm and the wall thickness is less than 1.2mm, the surface Rockwell hardness tester should be used to test the hardness of HRT or HRN.

For pipe stainless with an inner diameter less than 30mm and greater than 4.8mm, a special Rockwell hardness tester should be used to test the hardness. When the inner diameter is greater than 26mm, the Rockwell or surface Rockwell hardness tester can also be used to detect the hardness of the inside wall of the pipe.

The above are the details and testing methods of how the price of pipe stainless is affected by hardness. It can be found that the price of the product will not only be affected by its hardness, but also by different specifications. That is to say, if we choose stainless steel products with different specifications but the same hardness, their prices will differ.

The function of thick-walled pipe stainless

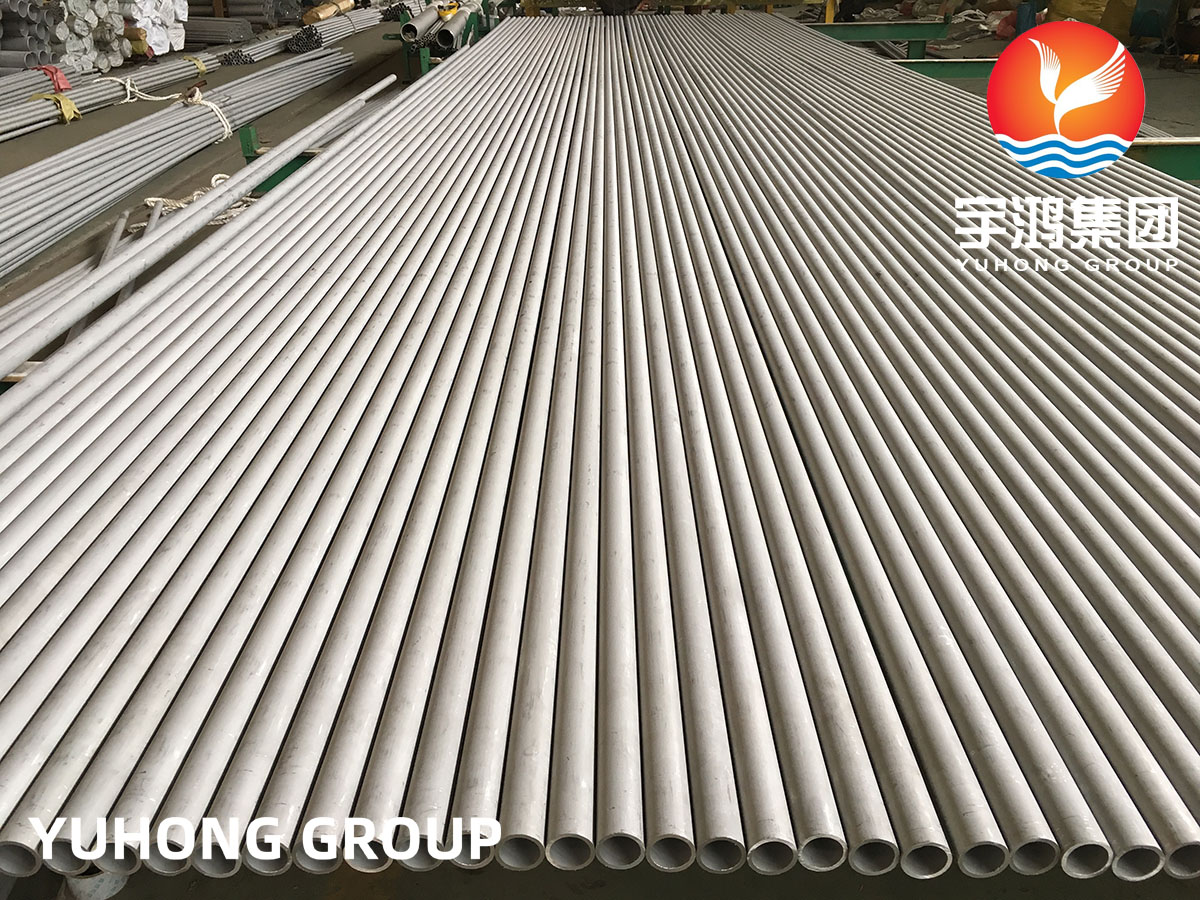

The scale covered by seamless steel pipe wall thickness is relatively wide, which can achieve small diameter and large wall thickness and large diameter and large wall thickness, but the length is generally limited. The wall thickness of stainless steel welded pipes can be relatively thin, and large diameter and small wall thickness and small diameter and small wall thickness can be achieved. Theoretically, how long the coil is, the welded pipe can be produced. Generally speaking, seamless pipes are more suitable for thicker walls, while welded pipes are more suitable for thinner walls.

In terms of wall thickness uniformity and concentricity, stainless steel welded pipes are better than stainless steel seamless pipes. Because the thickness tolerance of cold-rolled plates is relatively uniform and the deformation is uniform during the forming process. However, there are convexities in the welds, and different companies and specifications have different requirements for the weld height. In special cases, it can be welded first and then cold-drawn or cold-rolled. Seamless pipes are affected by equipment accuracy and material performance during rolling, and there are problems of uneven thickness and concentricity, but the roundness is better than that of welded pipes.

The uniformity and surface quality of pipe stainless welded pipes are better, and the bulging function is better. The uniformity of the cold-rolled plate is better than that of the pipe material, and the welded pipe generally uses online solid solution, and the heat treatment is uniform and the performance is more stable. But now the low-end and mid-range stainless steel welded pipes on the market do not have a heat treatment process, so the quality varies greatly. Stainless steel seamless pipes are sampled in different positions on the same pipe, and the performance is different, and some may vary greatly. During the heat treatment of seamless pipes, there is uneven heating and inconsistent cooling rate when the heat pipes are bundled and processed.

On the corrosion resistance function, the welded seam has been heat-treated to meet the material requirements. If the stainless steel welded pipe is not heat-treated, the corrosion resistance function is significantly lower than that of the stainless steel seamless pipe.

English

English