Petrochemical processing plants demand robust and corrosion-resistant components to withstand harsh environments and ensure operational efficiency. Inconel flanges, known for their exceptional strength and resistance to high temperatures and corrosive substances, are a popular choice in these settings. This guide will walk you through the essential steps on how to install Inconel flanges in petrochemical processing plants, ensuring a reliable and durable piping system.

Understanding Petrochemical Environments

Before diving into the installation process, it's crucial to comprehend the challenging conditions within petrochemical processing plants. Exposure to corrosive chemicals, extreme temperatures, and high pressure necessitates the use of materials like Inconel that can withstand such harsh environments.

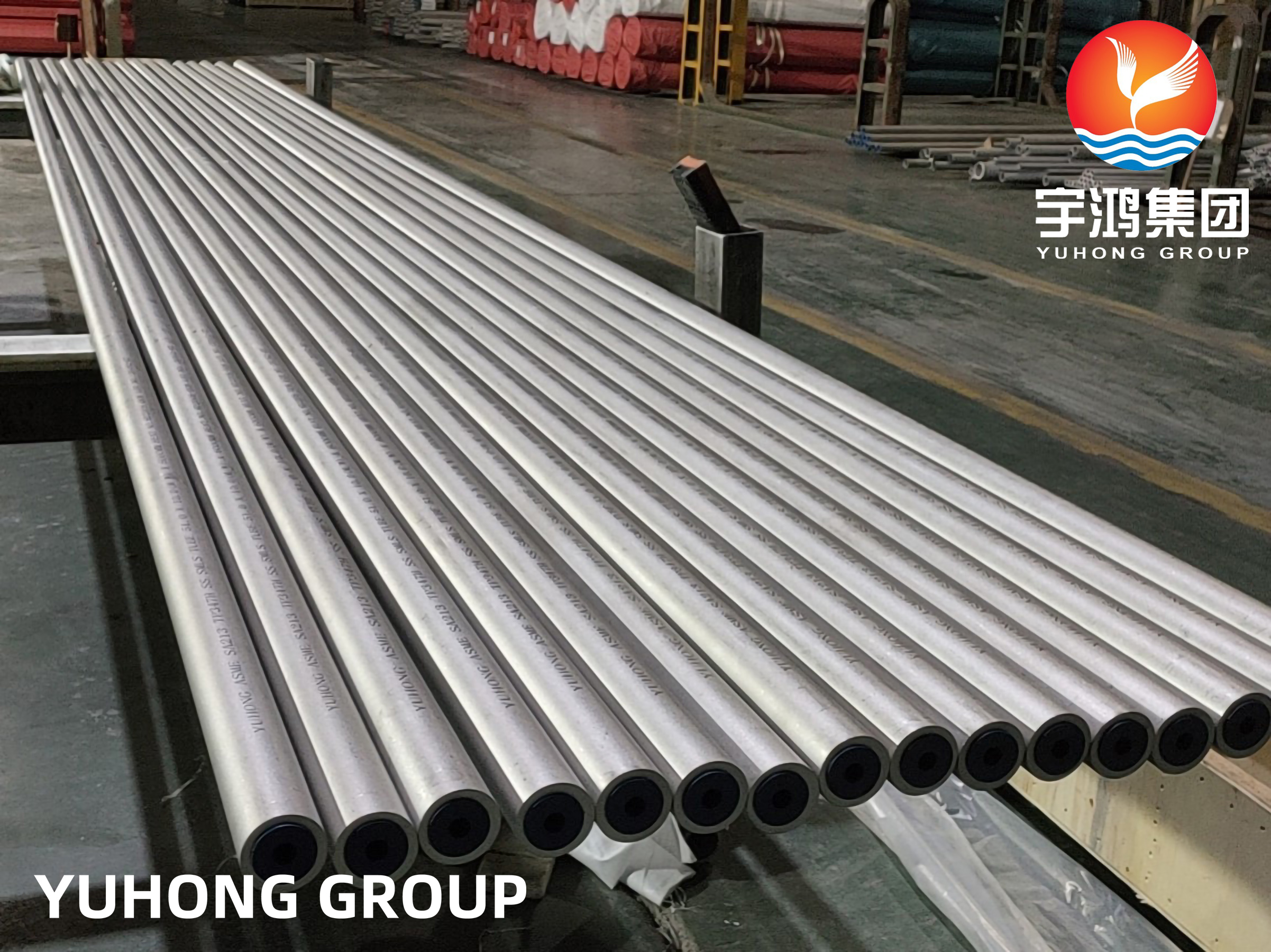

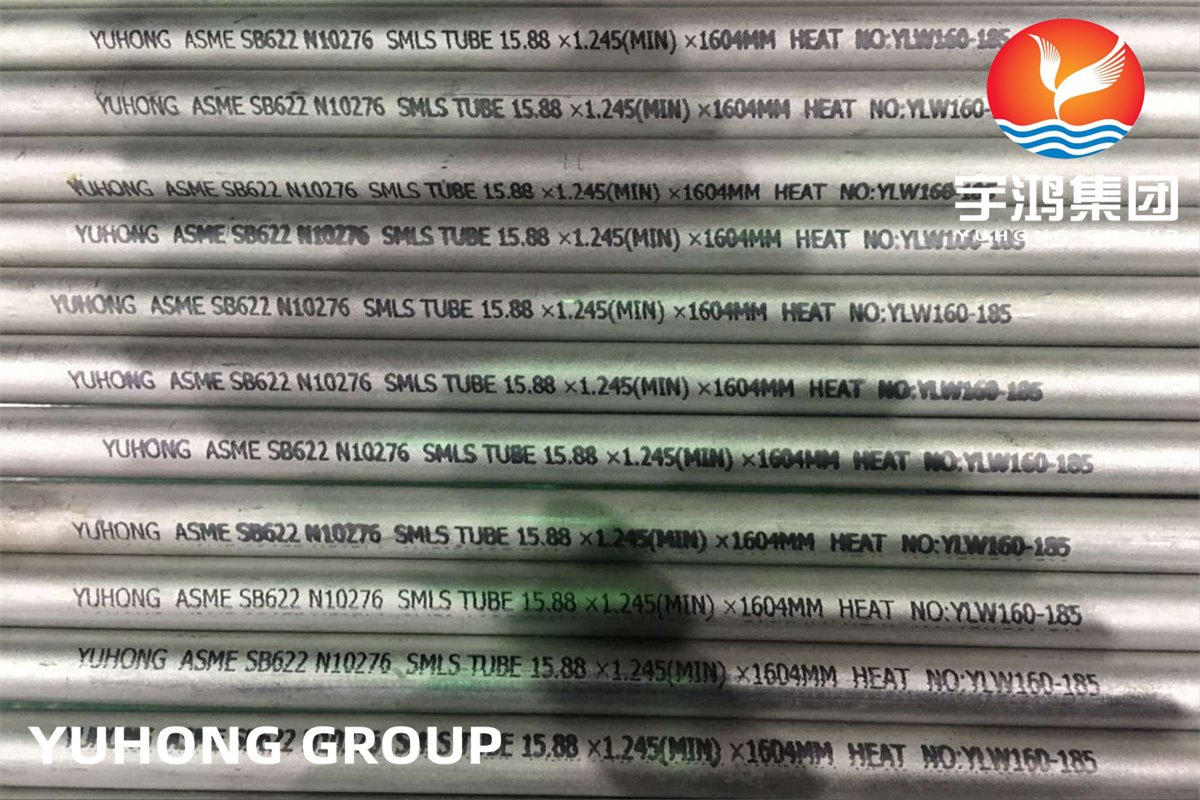

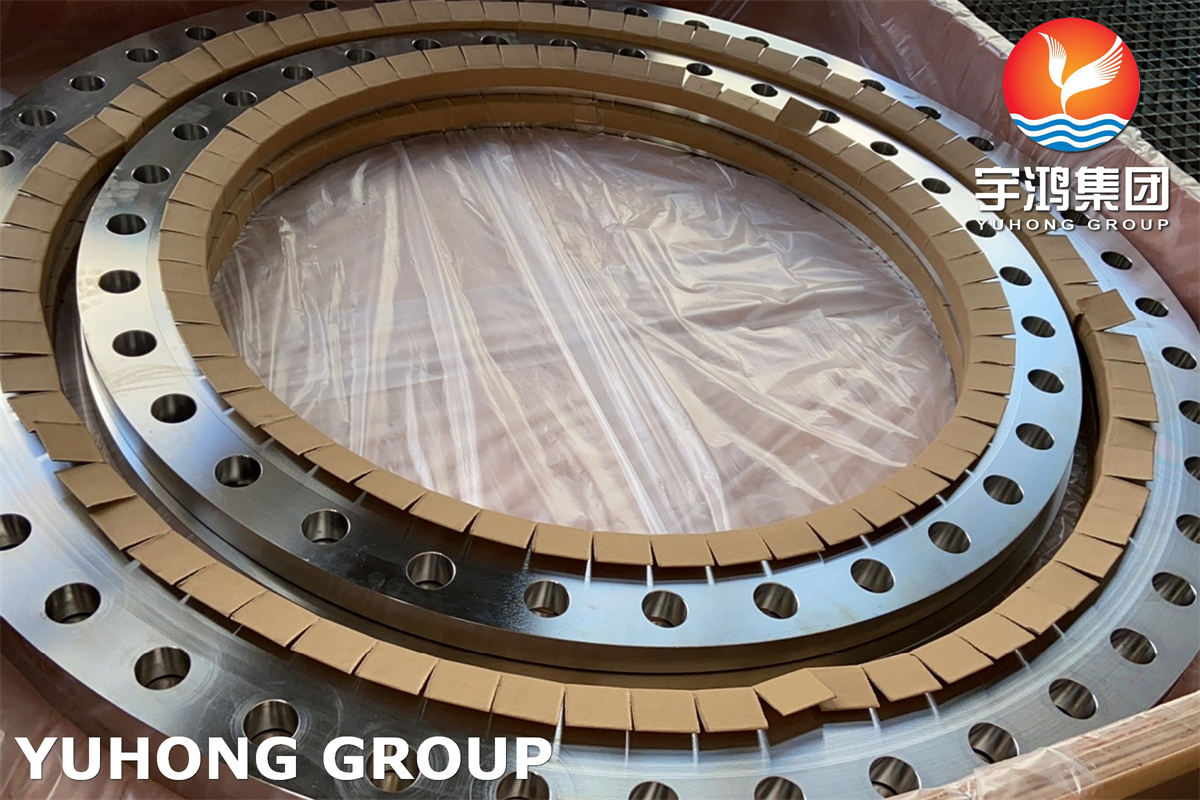

Selecting the Right Inconel Flanges

Choosing the appropriate Inconel flanges is a critical step in ensuring the longevity of the piping system. Consider factors such as flange size, pressure rating, and temperature resistance. Verify that the selected flanges meet industry standards and adhere to plant-specific requirements.

Pre-Installation Inspection and Preparation

Thoroughly inspect each Inconel flange before installation to identify any defects or damages. Clean the flanges to remove any contaminants and ensure a proper seal. Additionally, inspect the mating surfaces to guarantee they are smooth and free from imperfections that could compromise the integrity of the joint.

Flange Alignment and Bolting

Proper alignment is essential for a secure and leak-free connection. Align the Inconel flanges accurately, using alignment pins if necessary. Begin the bolting process, tightening the bolts gradually and evenly in a crisscross pattern to distribute the load uniformly. Refer to the manufacturer's torque specifications for the correct tightening sequence and torque values.

Quality Assurance and Testing

After installation, conduct thorough quality assurance checks to confirm the integrity of the Inconel flange connections. Perform non-destructive testing methods such as visual inspection, dye penetrant testing, or ultrasonic testing to identify any potential issues. Pressure testing should also be carried out to ensure the system can withstand the operational conditions.

Installing Inconel flanges in petrochemical processing plants demands precision, attention to detail, and adherence to industry best practices. By following the outlined steps, you can contribute to the reliability and efficiency of the piping system, ensuring that it can withstand the demanding conditions inherent in petrochemical processing. Always consult with industry experts and adhere to relevant safety standards to guarantee a successful and long-lasting installation.

English

English

_副本.webp)